Printing Academy

Welcome to PrintNinja’s Printing Academy!

At PrintNinja, we constantly strive to better our process and ourselves. We love learning more about all the cool things that we can achieve with offset printing. If you share the same passion for advancing your knowledge, here’s an intro guide to the entire offset printing process, complete with videos, photos, and expertise from those in the printing business. Exploring the pages in our Printing Academy will help you learn more about the process, so you’ll be able to understand what’s happening when you get your project printed with us. And we think that’s pretty cool!

Freshly updated customer reviews from TrustPilot

Introduction to Printing

This article serves as a basic introduction to offset printing.

Offset printing, also called lithography, uses a large printing press with a series of printing plates that transfer ink onto paper, which is then cut, folded, and bound to form a final product.

When you think of offset printing, think of the word transfer. Each step in this printing technique involves the transfer of images (text and art) from one material to the next. First, your images are digitally transferred onto a set of plates, which collect ink to transfer your images onto a rubber blanket that transfers images onto paper.

There are two primary types of offset printing: sheet-fed and web. The most common alternative to offset printing is known as digital or print-on-demand.

Sheet-Fed Offset

PrintNinja uses sheet-fed presses. These machines use pre-cut sheets of paper, called parent sheets, that are fed through the printing press one sheet at a time. They are best used for short or mid-range runs (250 to 10,000 units).

Pros:

- Highest quality printing

- Wide range of specialty options

- Low per-unit costs

Cons:

- High setup costs

- Medium minimum order sizes

Web Offset

Web offset printing presses use a roll of paper that is continuously fed through the printing press. They are far more complicated than sheet-fed presses and can be as large as an entire building. Web presses are used for high-volume printing (10,000+ units).

Pros:

- Extremely low per-unit cost

Cons:

- Extremely high setup costs

- Large minimum order sizes

- Lower quality than sheet-fed

Digital (POD)

Digital printing (also known as Print-On-Demand or POD) is not an offset printing method, but it’s a good one to understand. Digital printing uses equipment similar to a large home laser or inkjet printer. This approach is best used for small runs (1 to 150 units).

Pros:

- No setup costs

- No minimum orders

Cons:

- High per-unit costs

- Less consistency in color and quality

- Fewer specialty options

Digital Offset

Digital offset is a recent technological innovation in the printing industry. It offers the best of both digital and offset: there are no setup costs and low minimum orders, there’s a fast turnaround, and the quality is superior to traditional digital and comparable to traditional offset. Like traditional offset, the process still involves an image plate. The printing imaging plate is electrostatically charged using lasers inside the press, then the areas of the plate with charge attract ink from various coated ink rollers, which is then transferred to a rubber blanket and, finally, your project.

This process is made possible through the patented technology of the HP Indigo line of printing presses and is essentially a fusion of digital and offset printing. Indigos use ink and paper like traditional offset, whereas other digital printing is commonly toner based.

Pros:

- No set up costs

- Low minimum orders

- High quality printing

- Fast production time

Cons:

- Limited specialty options

- More expensive than offset at high quantities

What Can You Print with Offset?

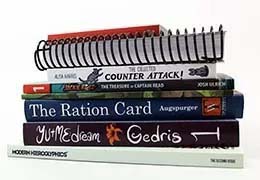

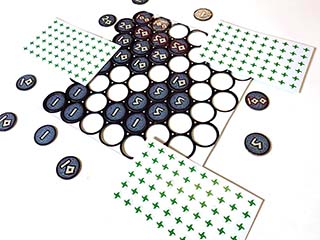

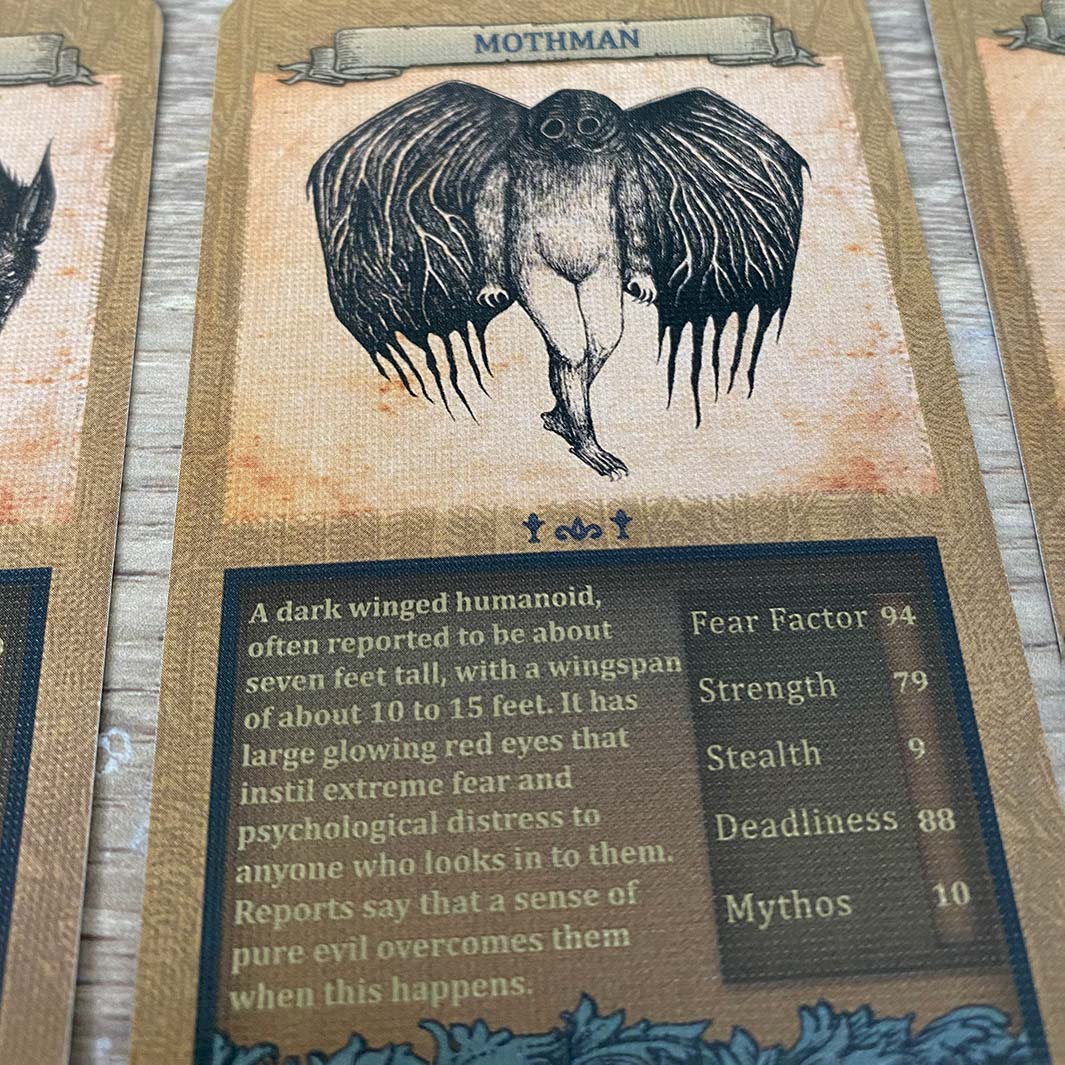

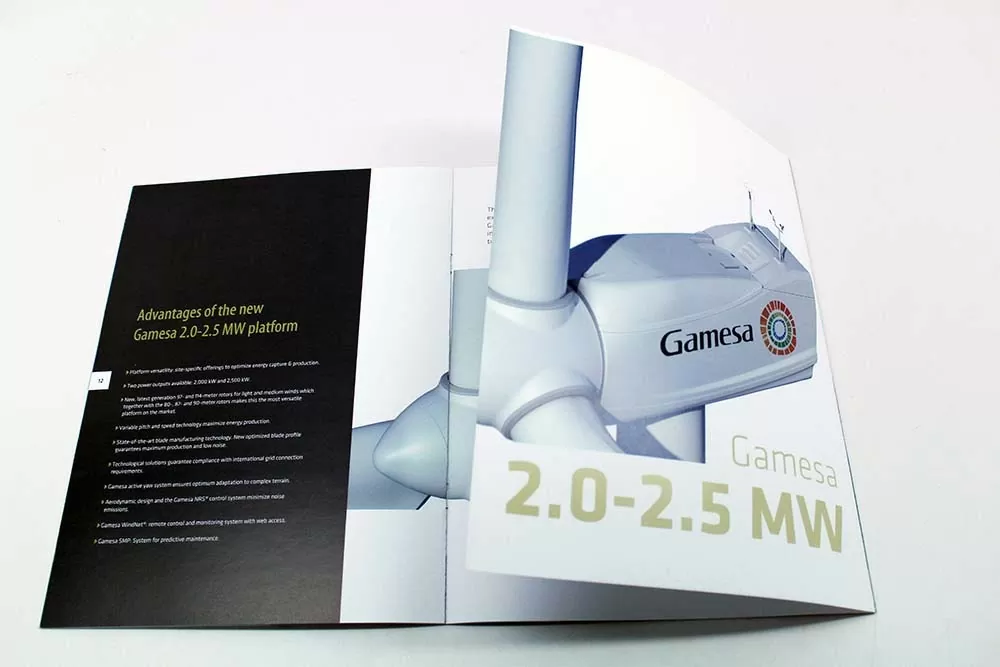

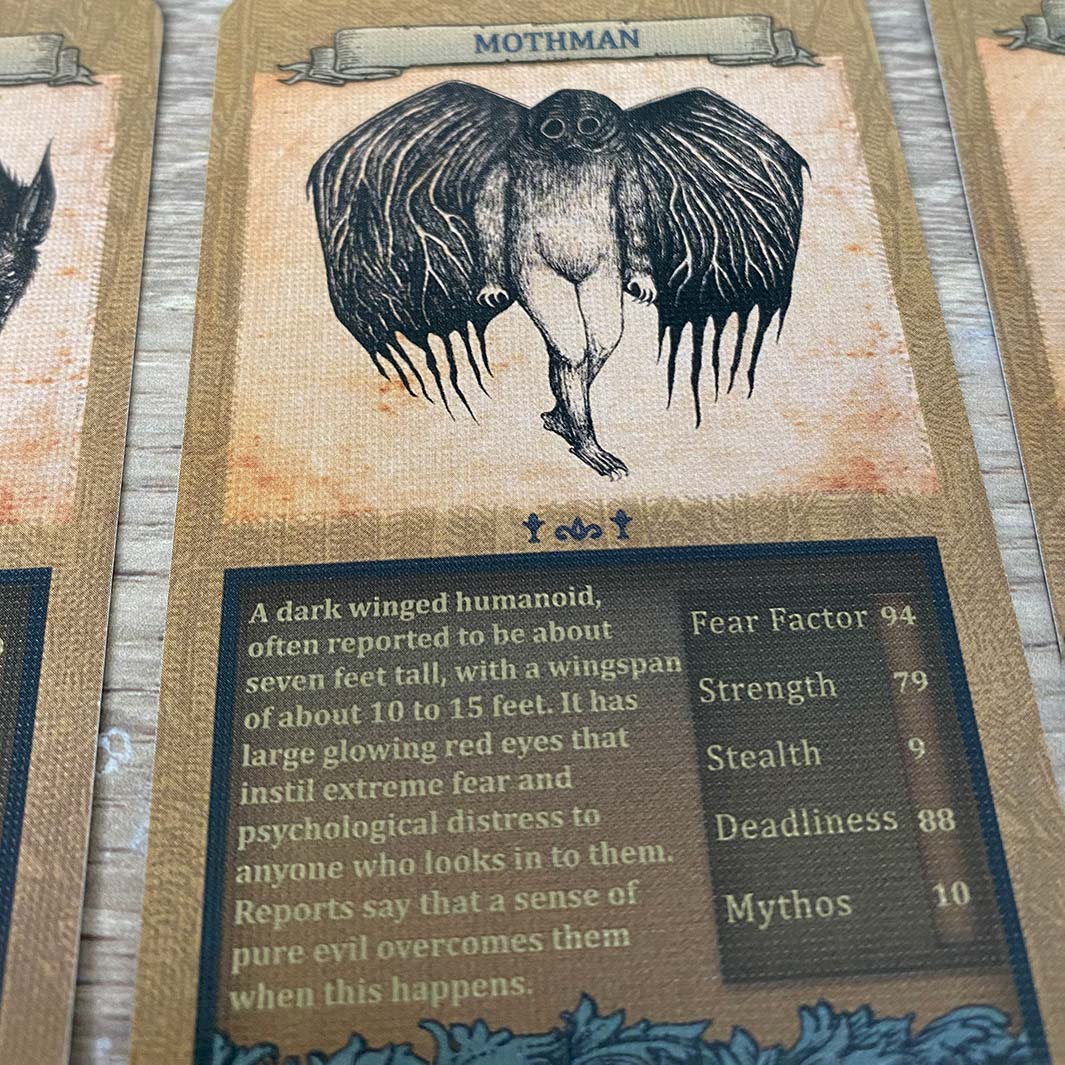

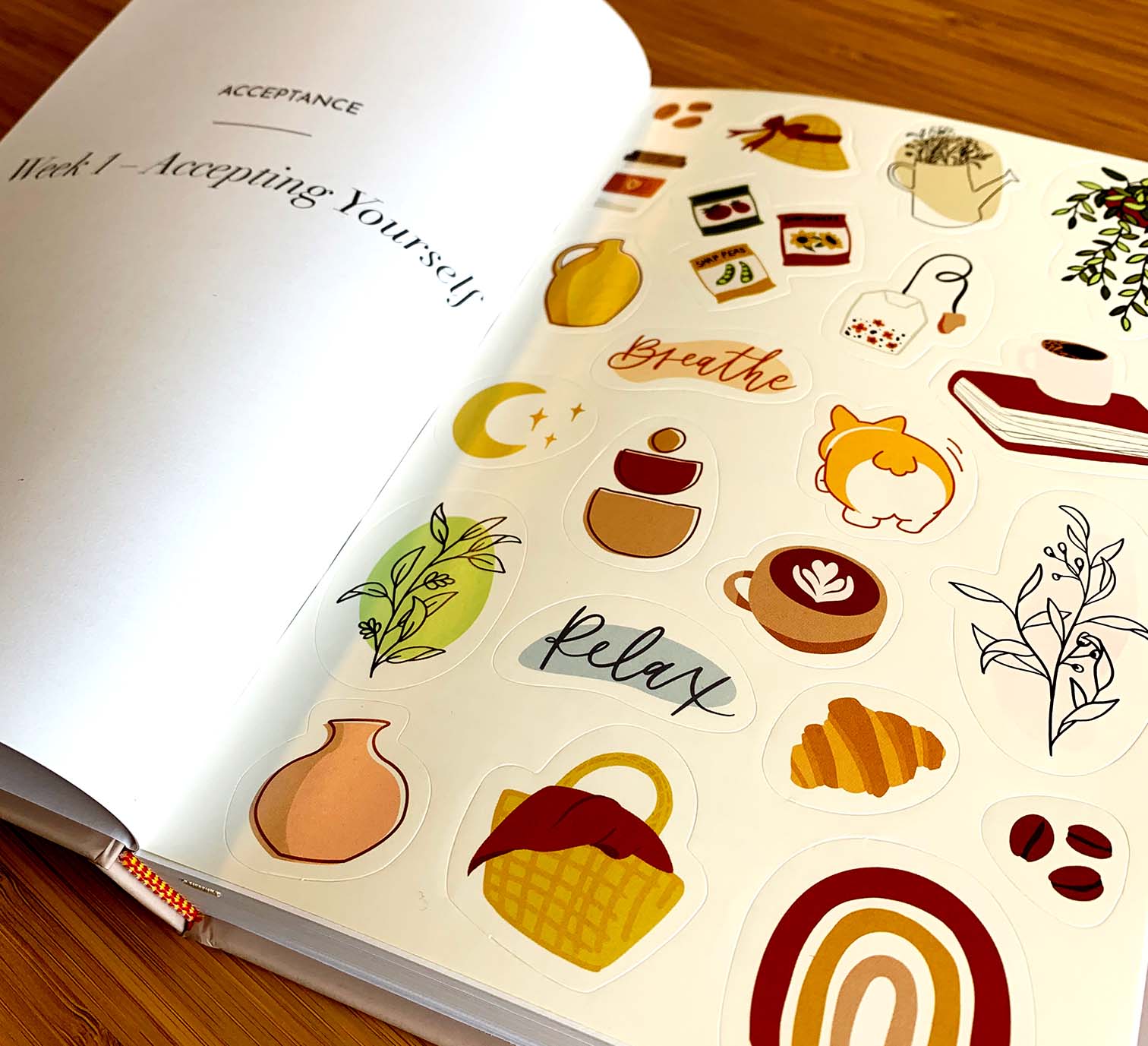

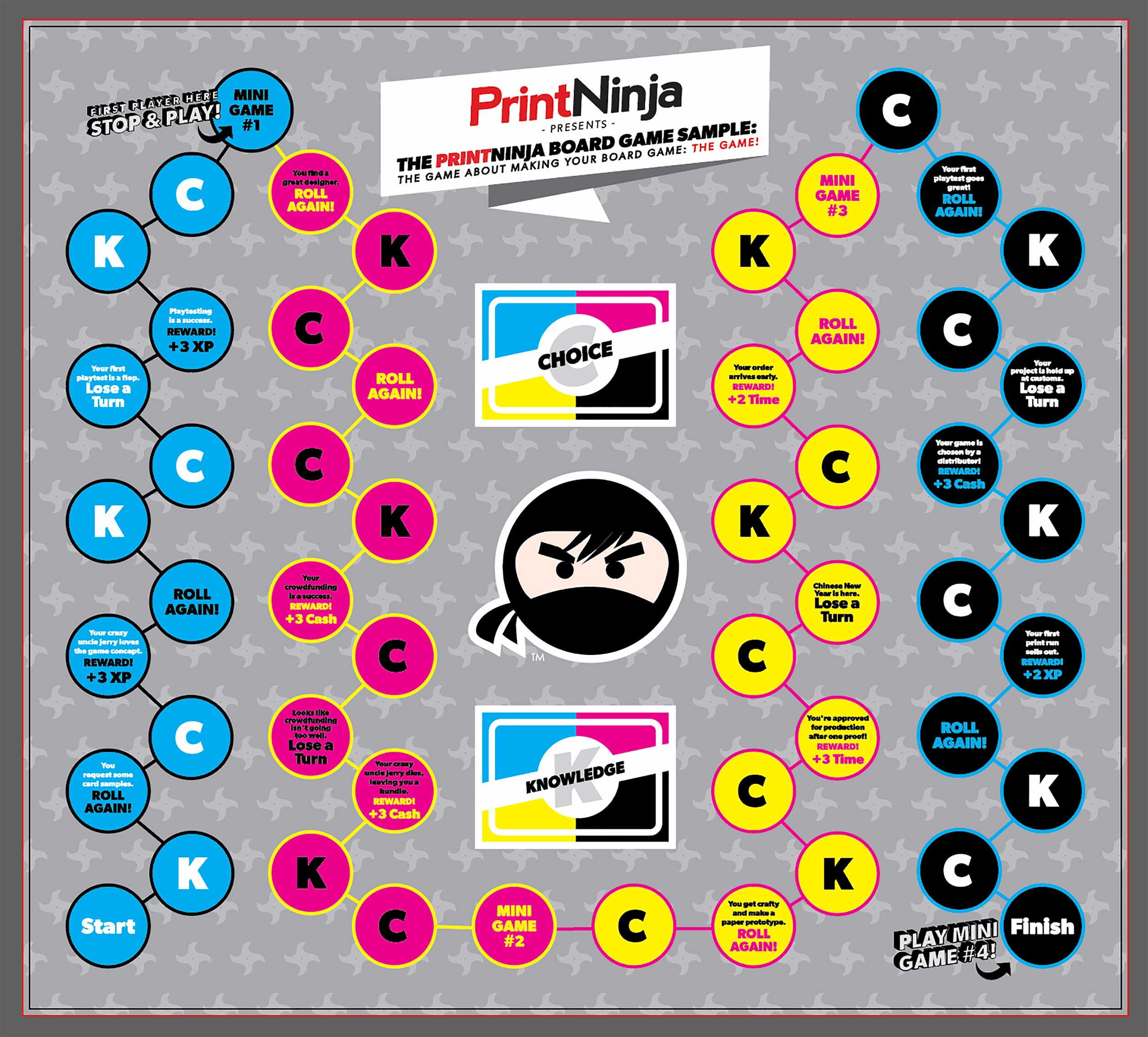

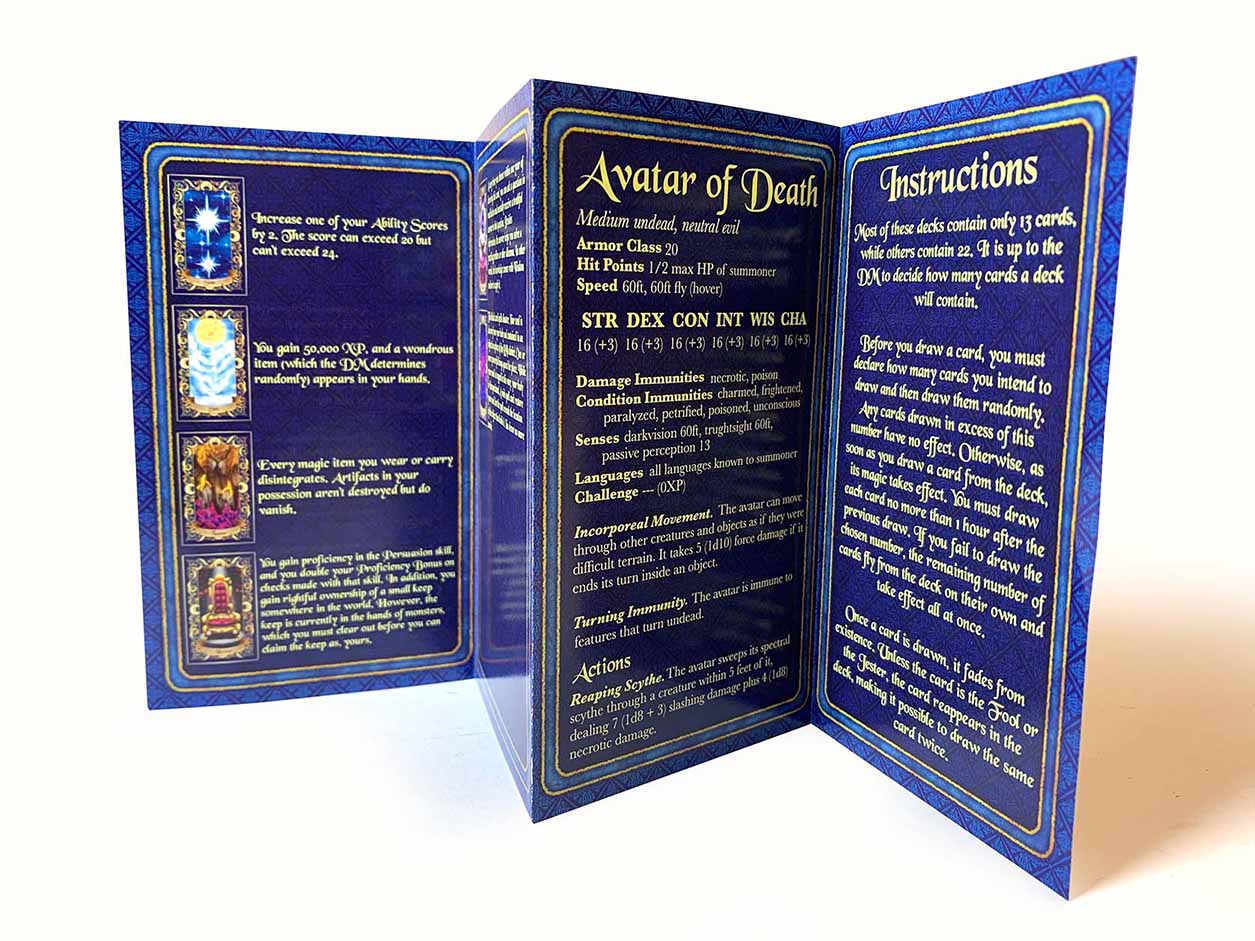

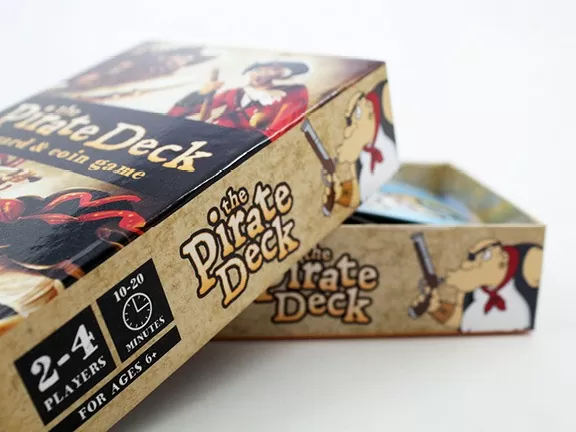

Offset printing can be used to print on paper, cardboard, plastic, and even chocolate! This printing method is a popular choice for card and board games, record jackets, and multi-page projects. Games and books follow the same printing process, but post-press is where the similiarties end.

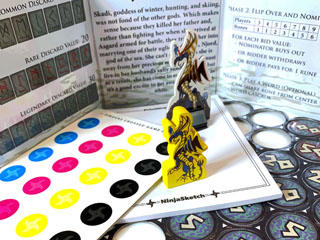

Most of our Printing 101 resource pages focus on four-color sheet-fed offset printing since those are the machines used by PrintNinja’s factories. These presses use four colors of ink — Cyan, Magenta, Yellow, and Black (CMYK) — to produce the vast majority of full-color projects printed worldwide.

Most of our Printing 101 resource pages focus on four-color sheet-fed offset printing as well as digital offset printing, as those are the machines used by PrintNinja’s partner facilities and domestic print shop. These presses use four colors of ink — cyan, magenta, yellow, and black (CMYK) — to produce the vast majority of full-color projects printed worldwide.

Freshly updated customer reviews from TrustPilot

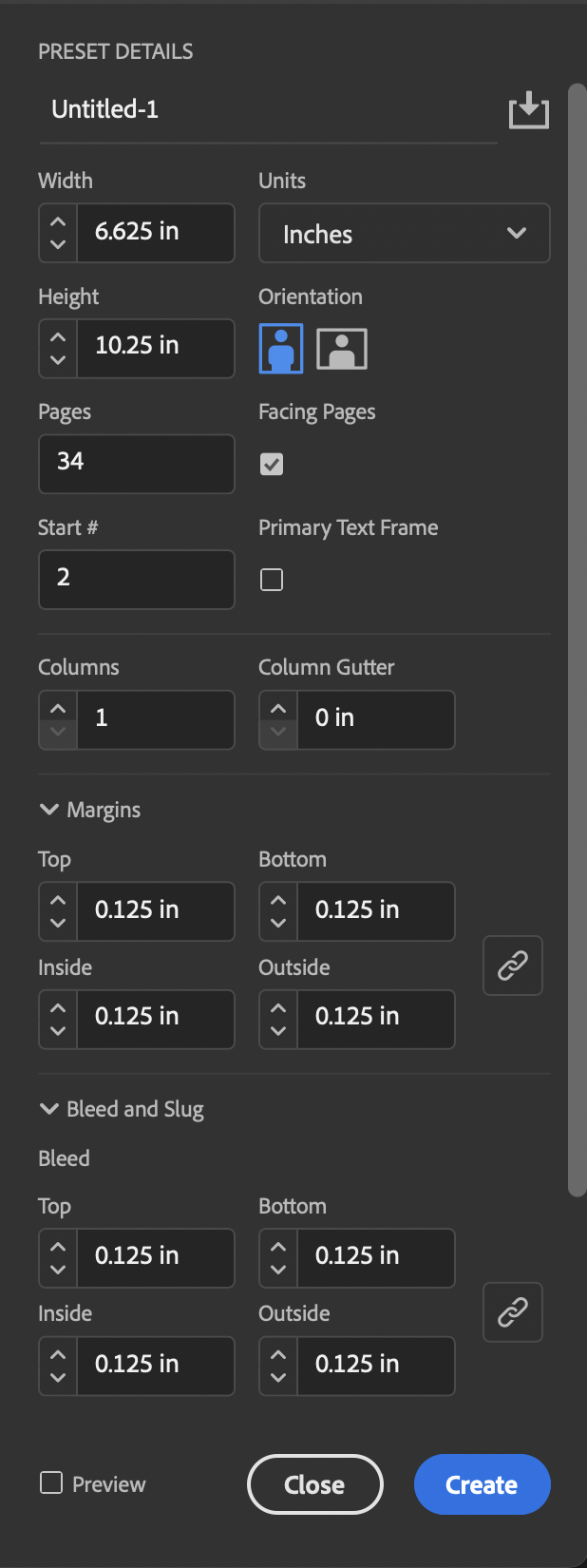

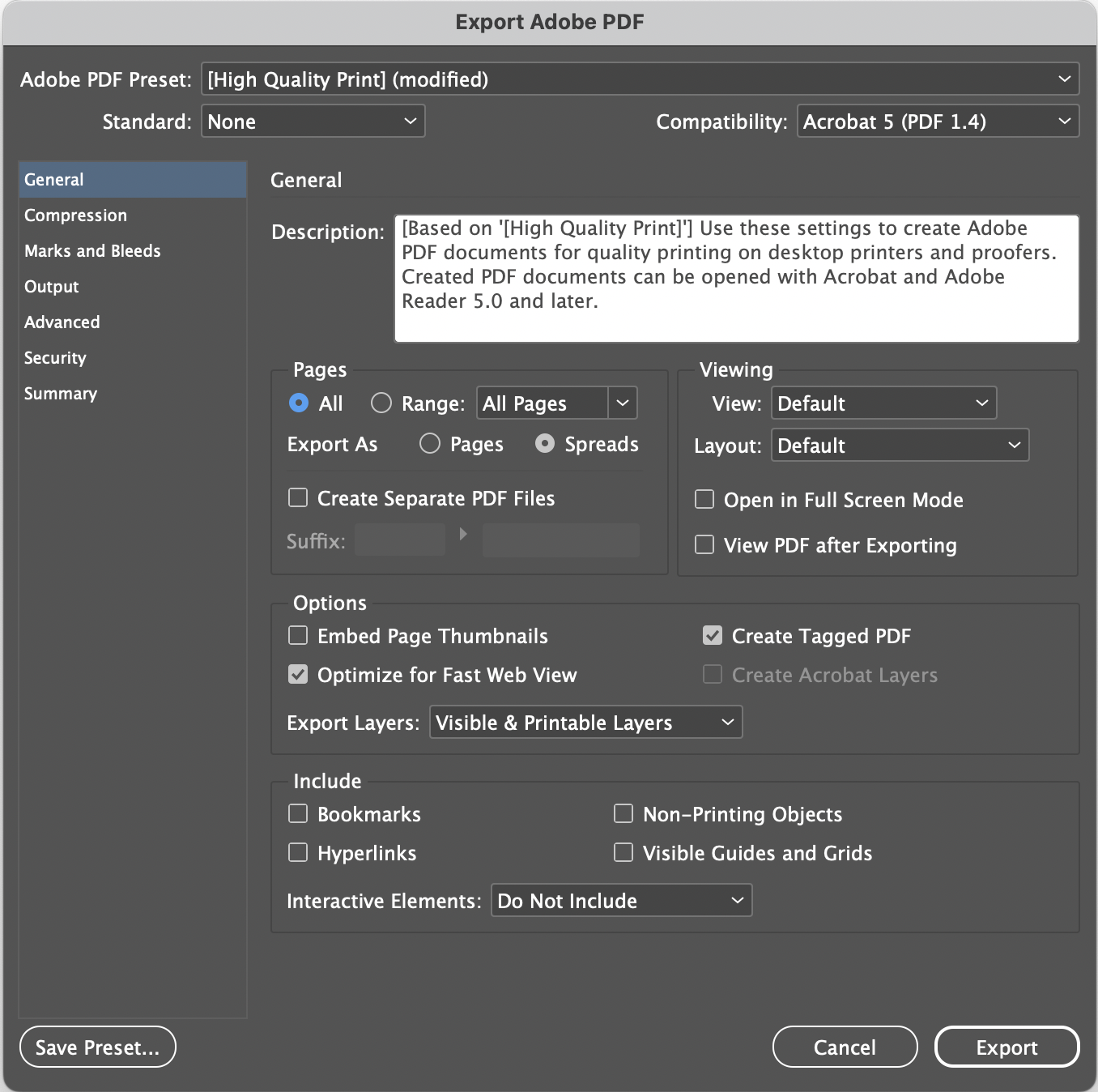

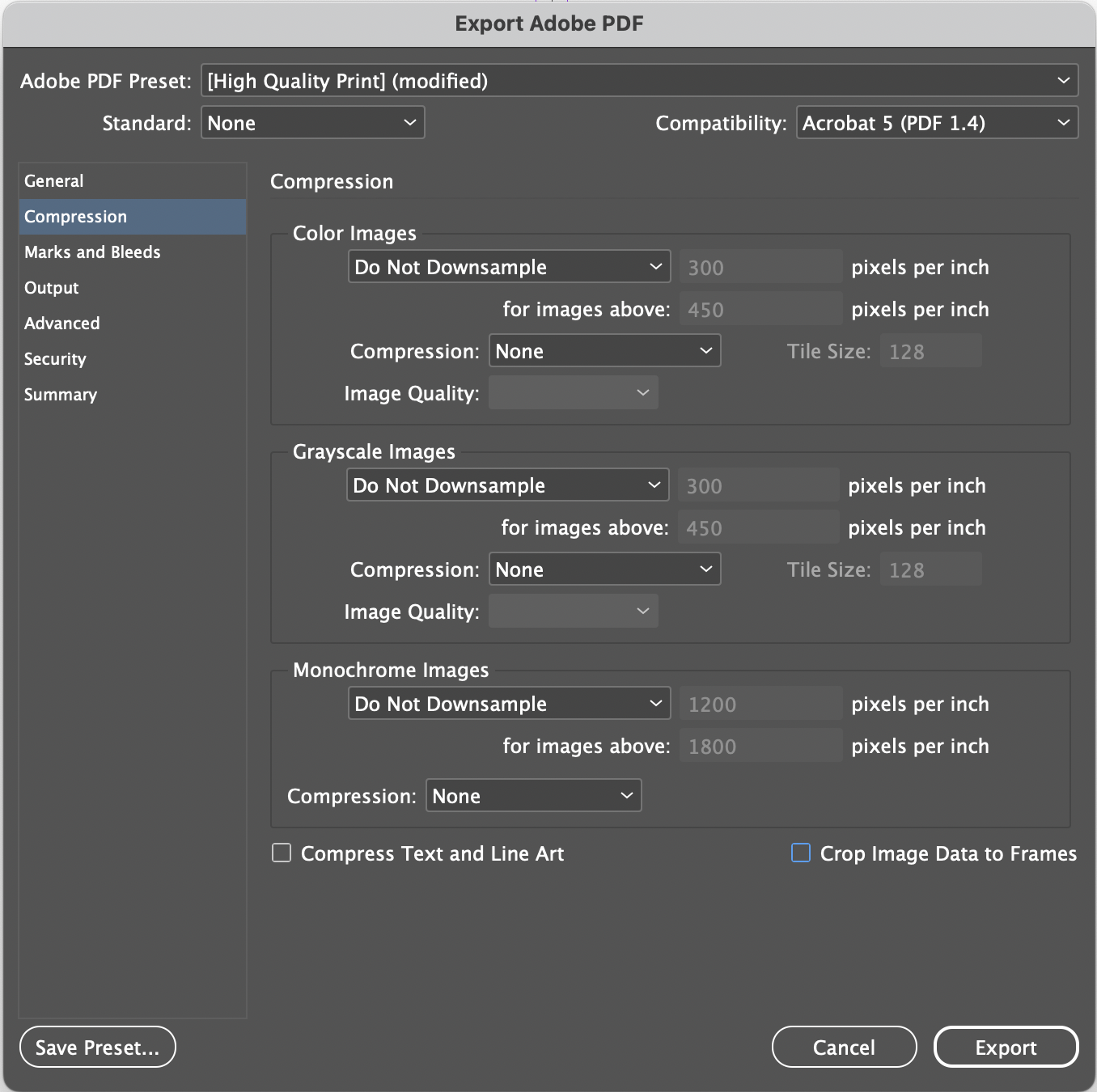

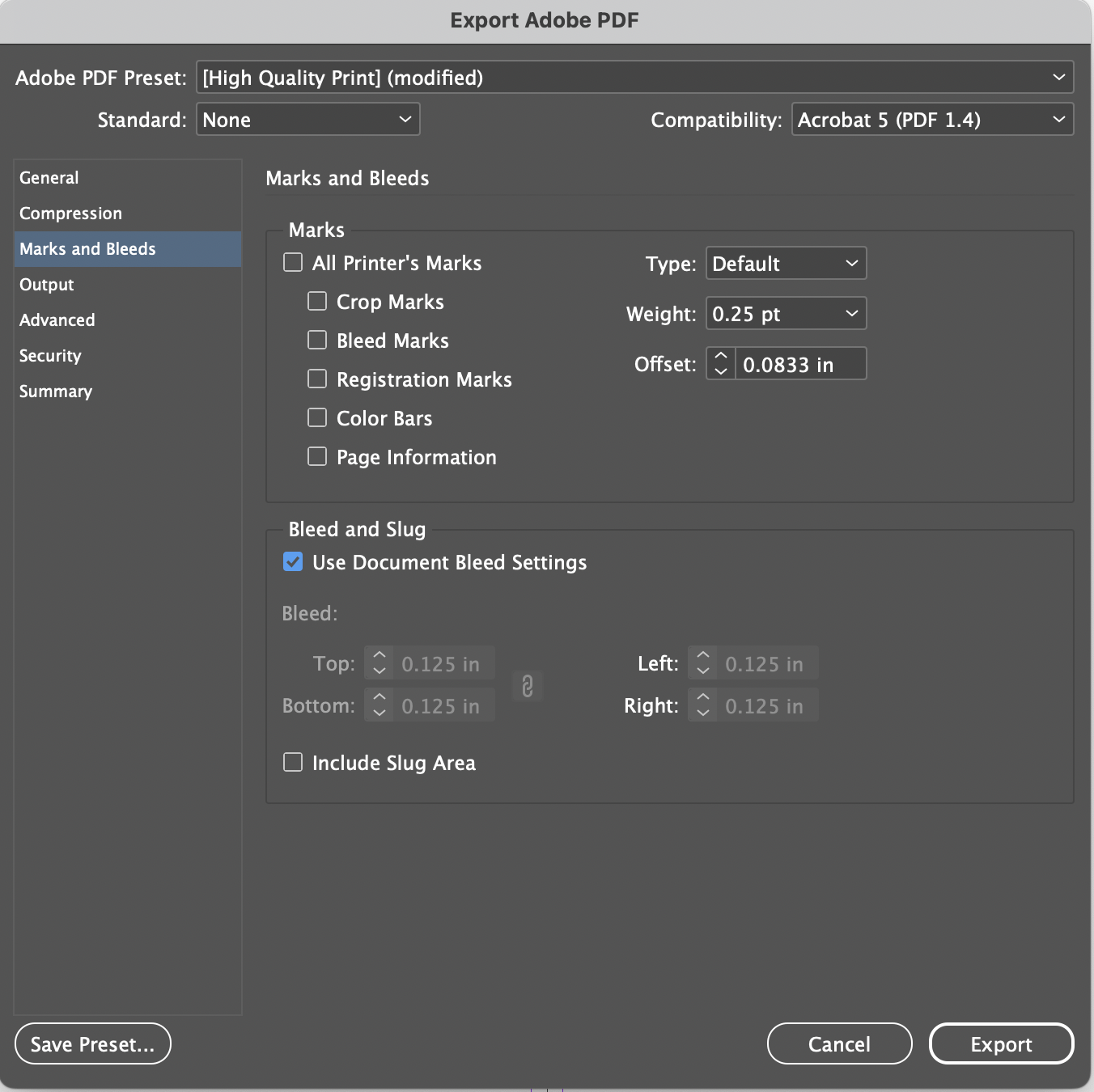

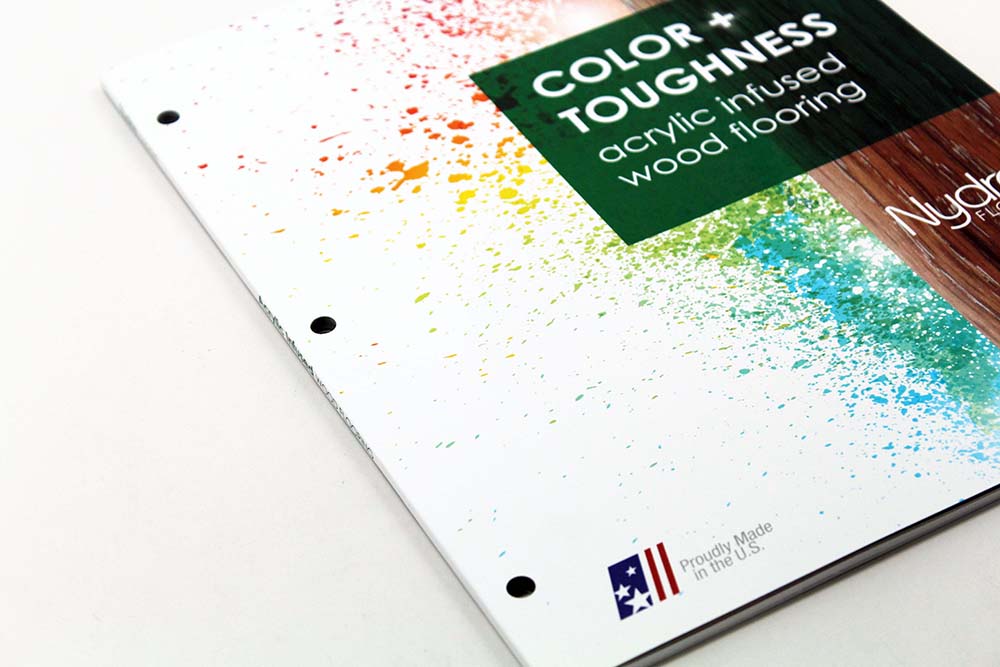

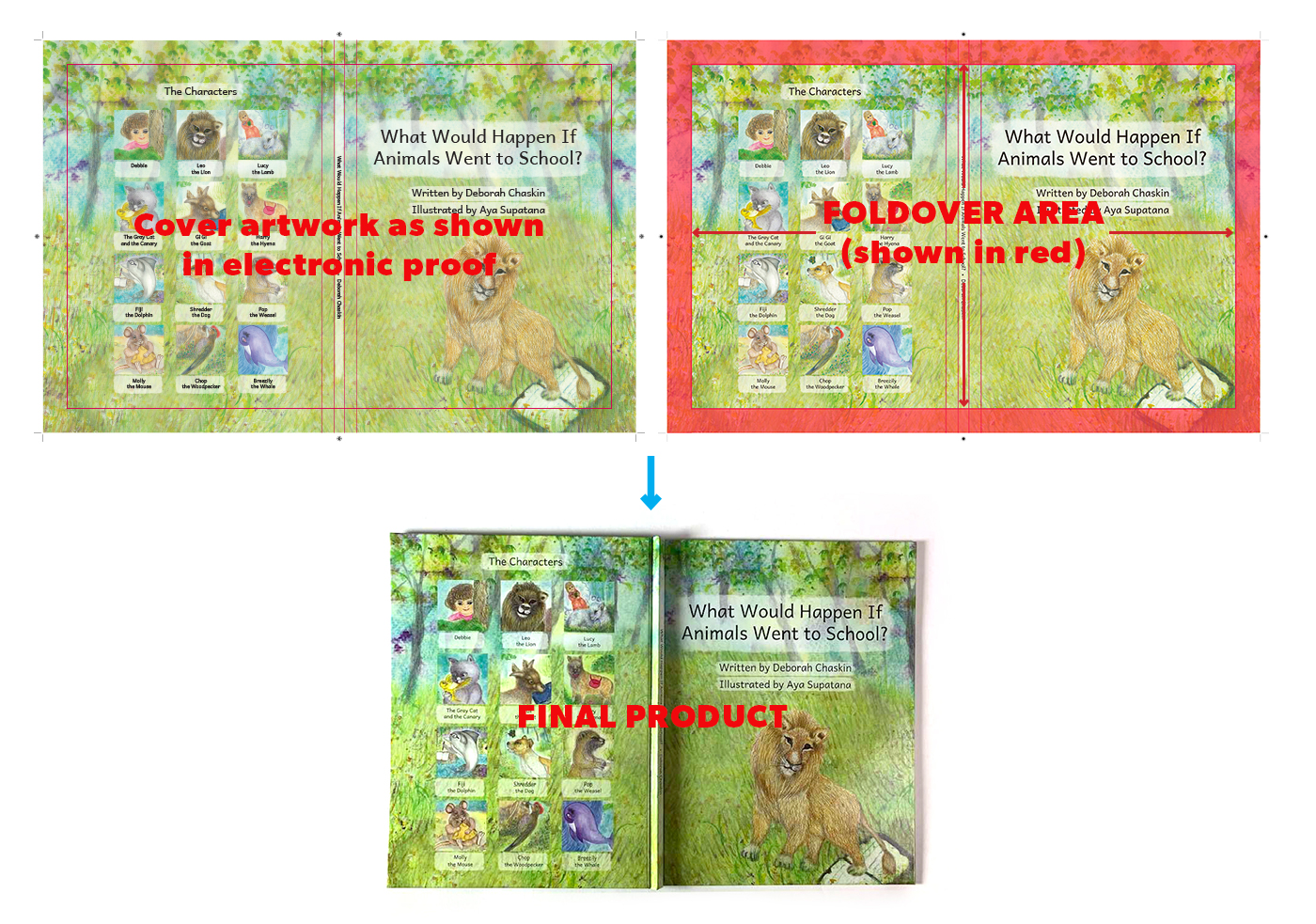

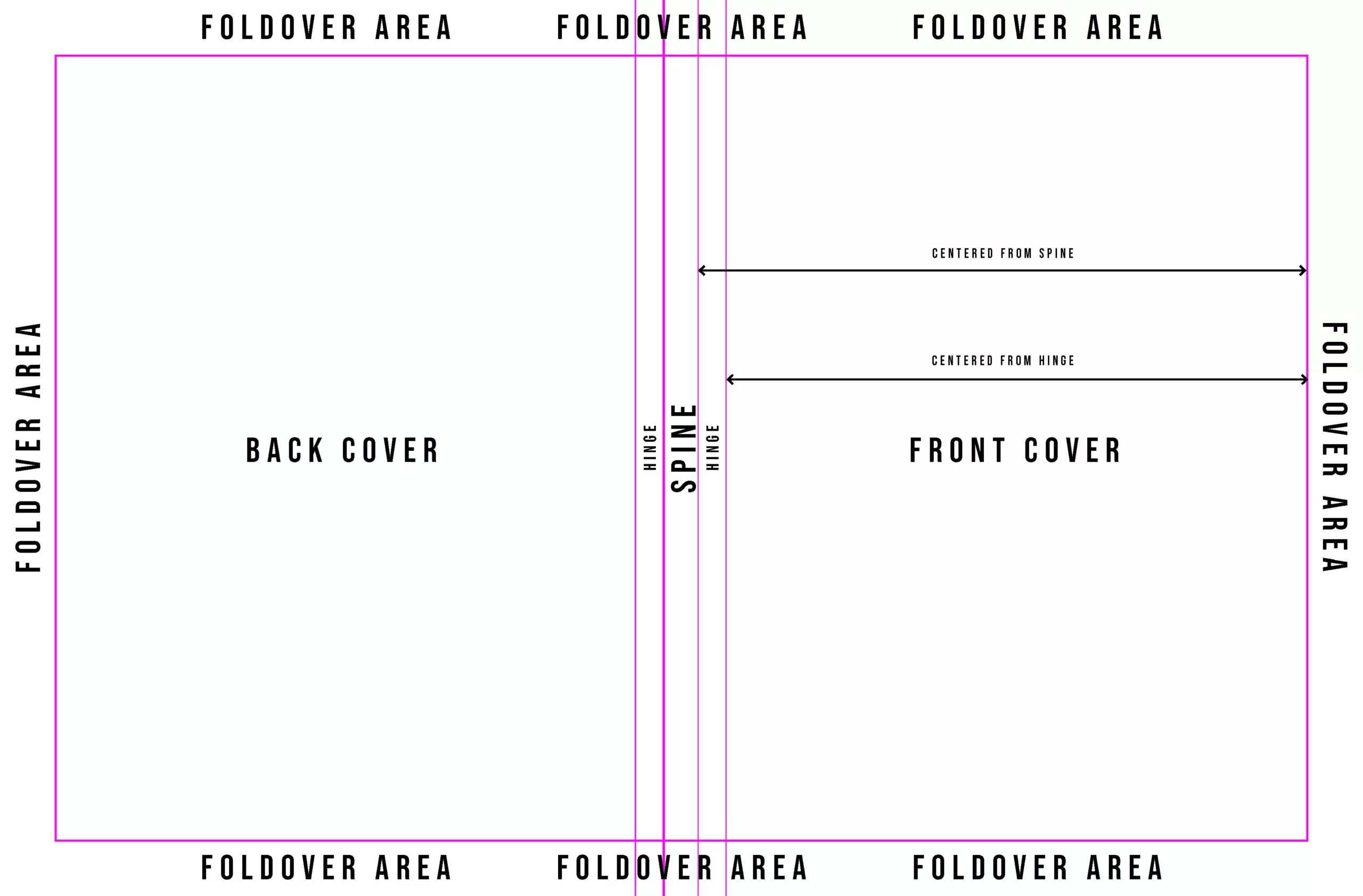

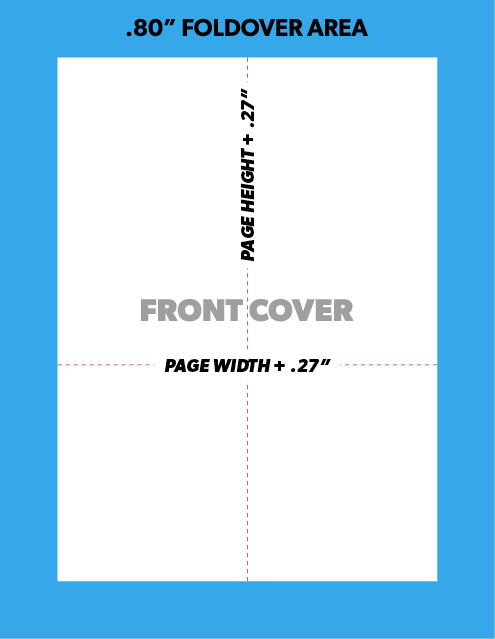

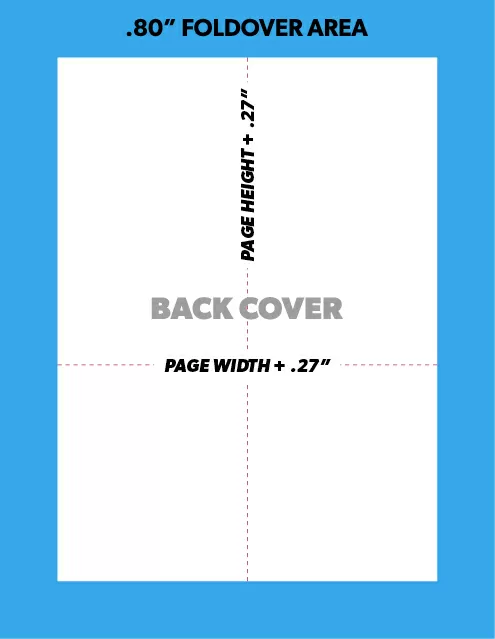

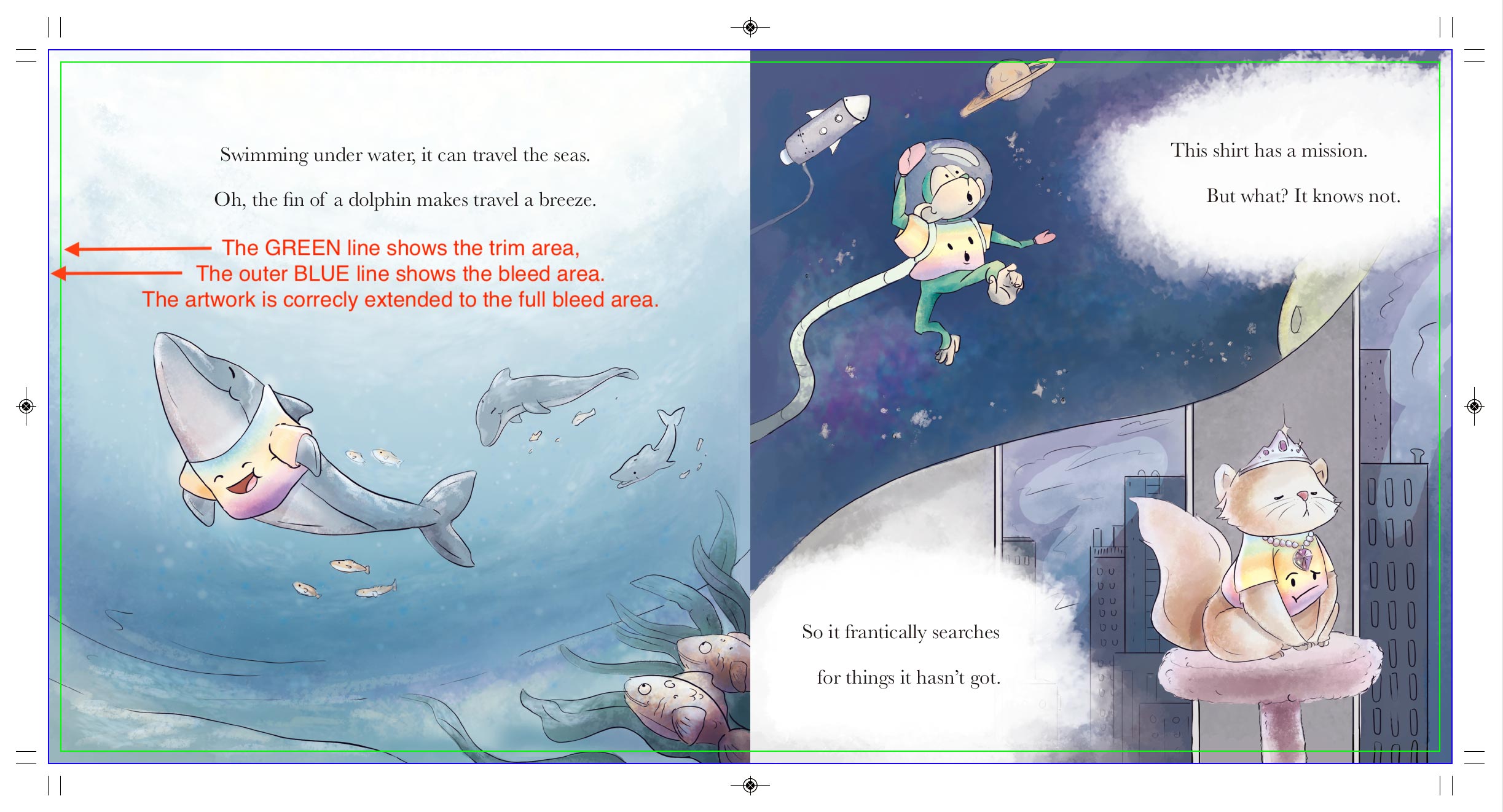

Pre-Press

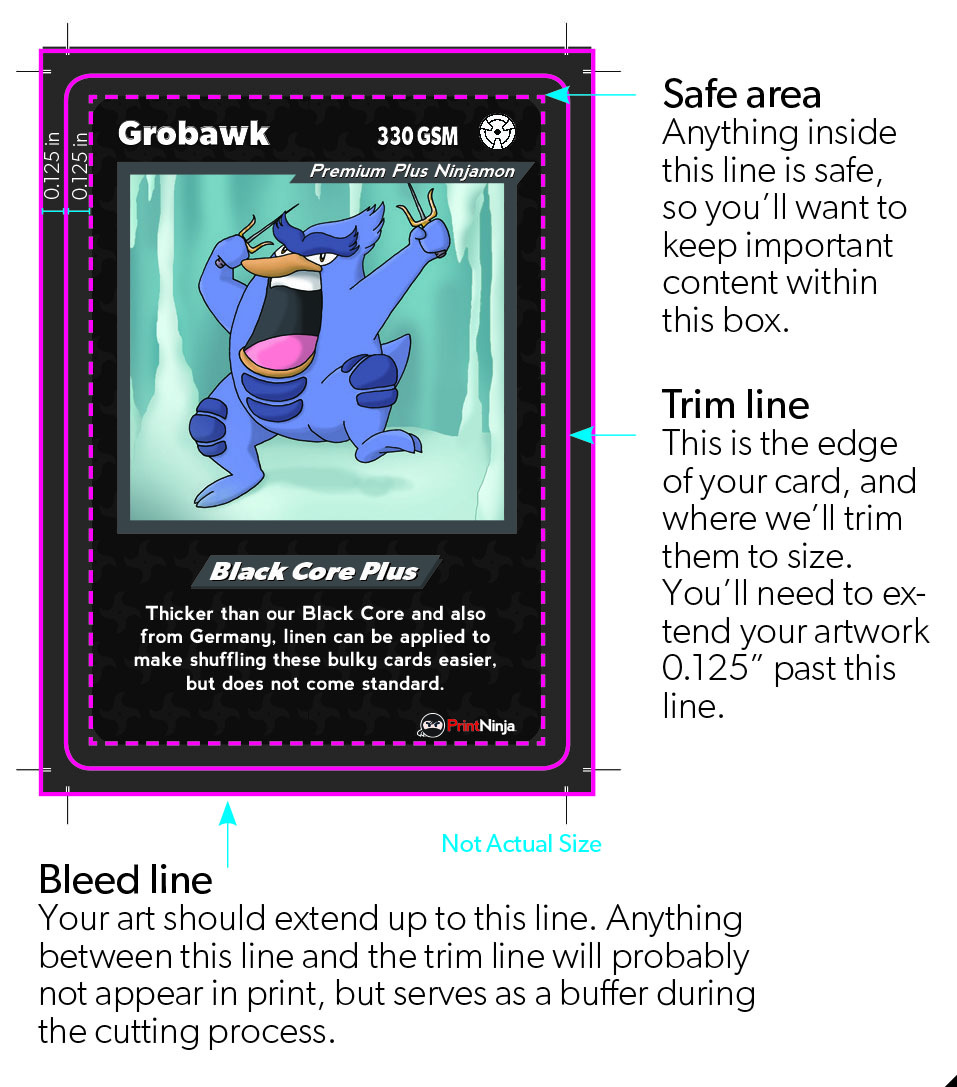

In the prepress production phase, an expert technician will review your files, both manually and through preflight software, for any sign of a problem that may cause production errors. An electronic proof is issued once your PDF files pass the preflight inspection. We provide electronic proofing to all of our customers for free, and all projects are required to go through this process — unless you’ve printed with us before and are using the exact same production files. When you receive your electronic proof via email, you may have suggestions from your prepress expert for changes that should be made to your files before sending them into production. You’ll also notice that printer’s marks have been added to your files. These are special marks to indicate different elements such as trim, bleed, and center. If requested, hard copy proofs (for books and games) may also be created and sent to you for approval, usually for color purposes.

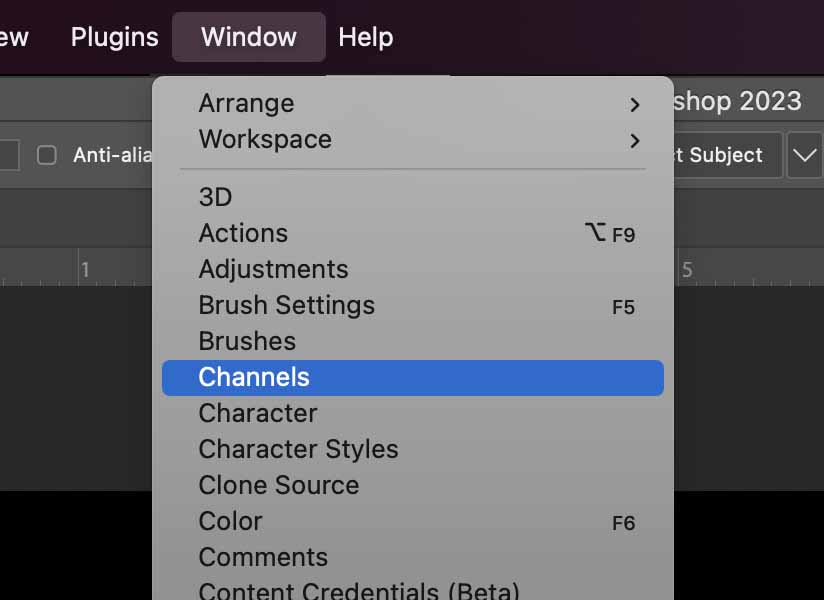

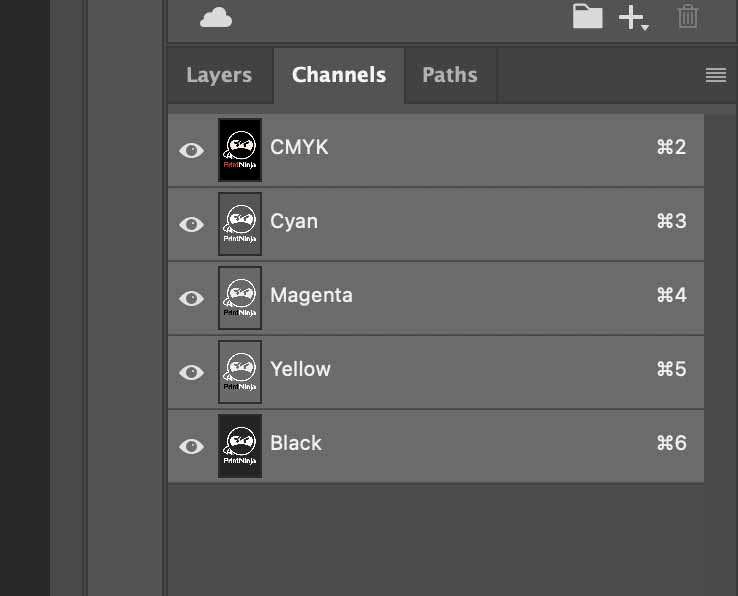

Once you have approved your proof and sent your files to press, the next phase in prepress production is that your files are output through a process called the RIP (Raster Image Processing). During this part of the prepress production process, your images are separated into four colors and output onto four metal printing plates – one plate for each of the colors of cyan, magenta, yellow, and black (CMYK). These thin metal plates are sturdy enough to be used for many thousands of printing impressions, yet also flexible enough to wrap around a rotating cylinder inside the printing press.

Pre-Press Production Chapters:

Freshly updated customer reviews from TrustPilot

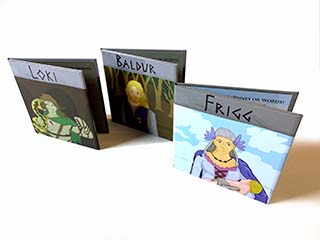

Proofs

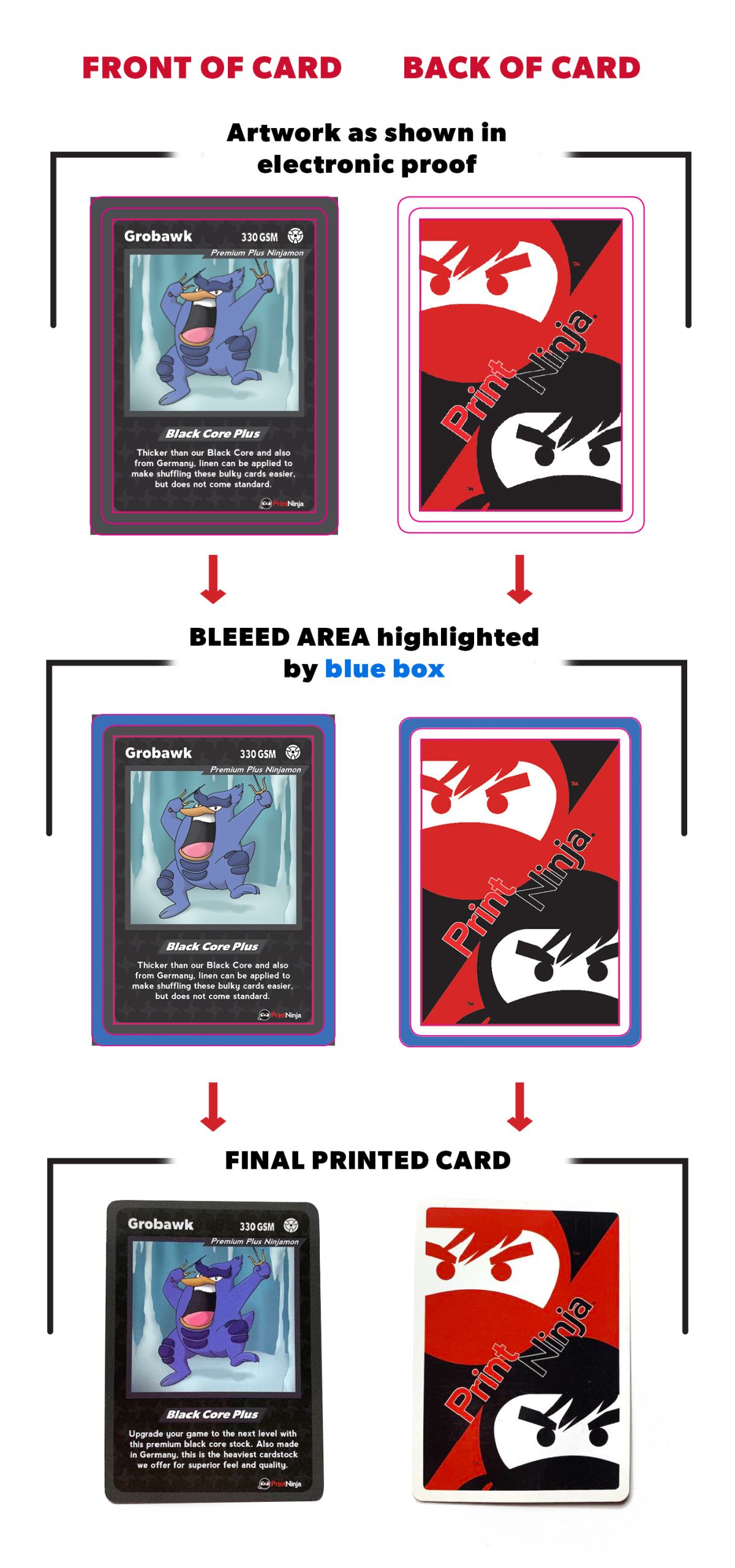

A proof is an electronic file or physical product meant to give an idea of the way your project will turn out when printed.

Electronic Proofs

Also known as a soft proof, most printers will provide electronic proofs for free because generating them is a necessary step that must be taken before printing. An electronic proof is done for any file that will be printed: interior pages, book cover, game board, game box, cards, instructions, etc. A prepress expert will look over your files for a number of issues, usually putting them through preflight software to do computerized checks as well.

A few preflight fundamentals:

- Image Resolution (300dpi minimum)

- Color Profile (CMYK, not RGB)

- Inclusion of Bleed

- Safe Zone Issues

- Pagination Issues

Prepress experts will double check that everything is accurate and may provide some suggestions if they find problems with your files. They’ll also typically add printer’s marks to indicate where the files will be trimmed, and then they’ll send the final file to you for your approval.

In general, electronic proofs are effective for double-checking content, pagination, and layout. However, electronic proofs cannot accurately portray how colors will look when printed.

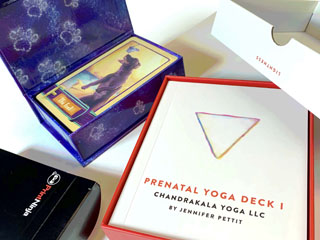

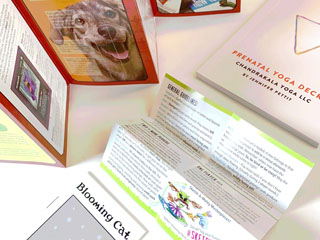

Hard Copy Proofs – Books and Cards

Hard copy proofs, also known as physical proofs, are highly recommended for those who are printing offset for the first time as well as for those who have specific color requirements. This option typically includes one or several press sheets of a project (usually 8 pages of content per press sheet) printed on an offset press using the actual paper and finishes to be used in the final product. Overall, physical proofs give a much more accurate feel for the way that color translates to the printed page.

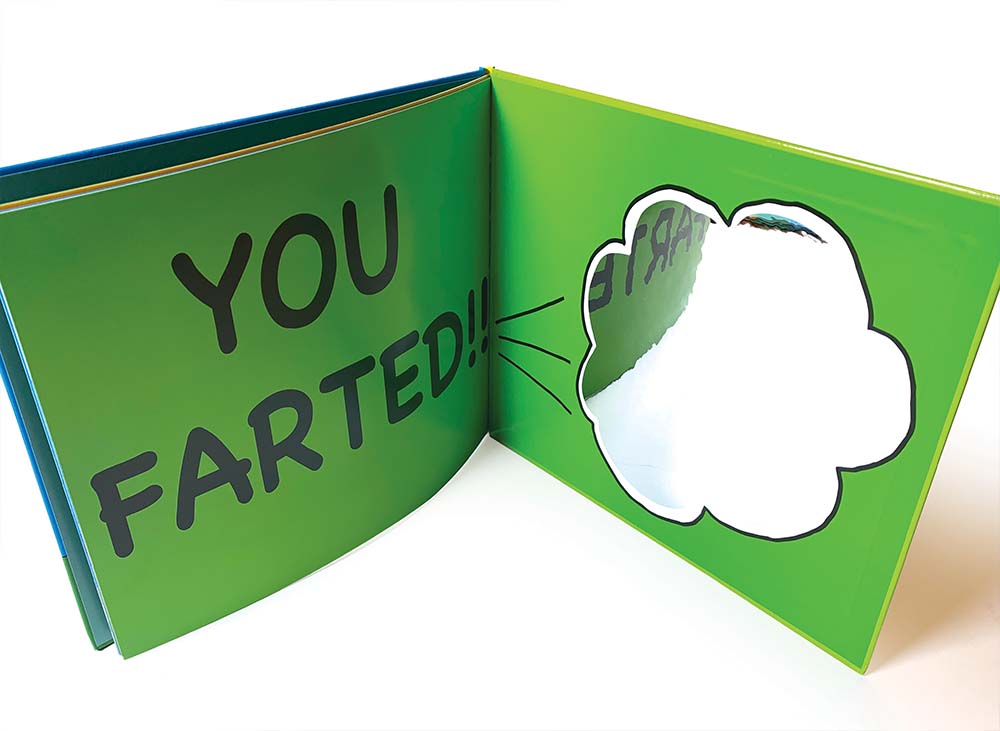

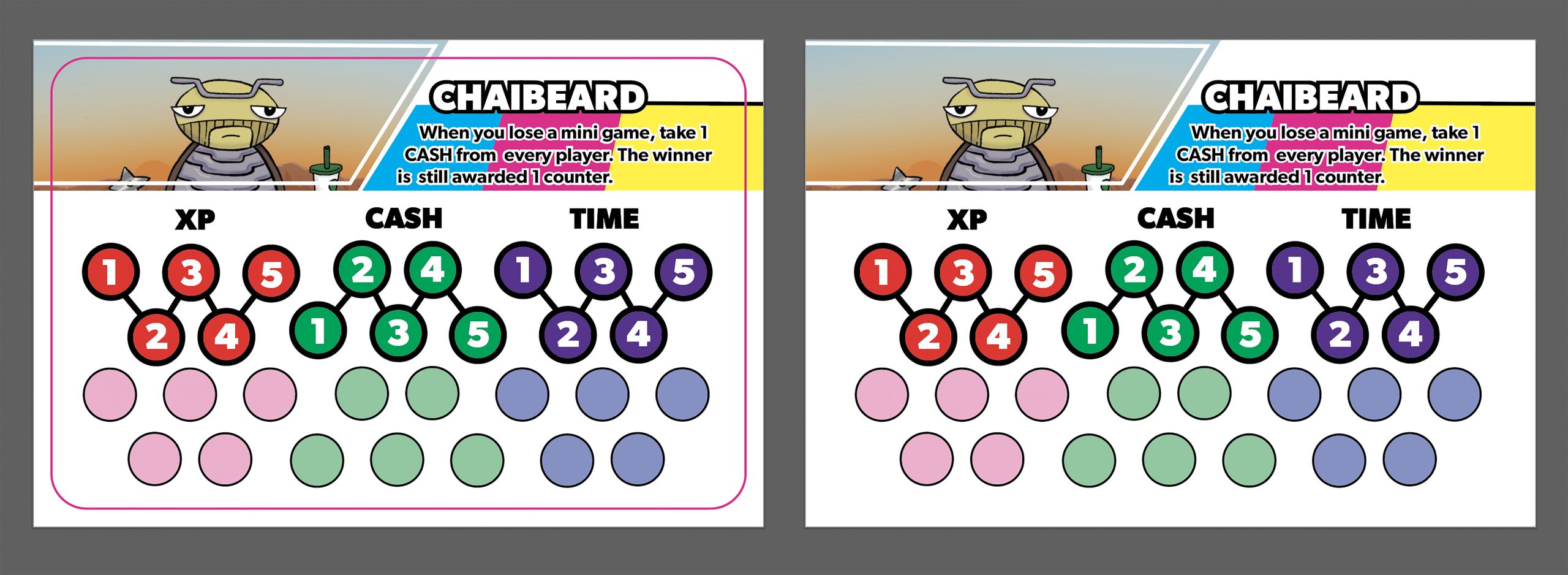

Hard Copy Proofs – Board Games

Hard copy proofs are not prototypes, although they can act as one. A prototype is typically your minimum viable product, while a proof is a closer representation to your final product. Both terms are used interchangeably in the industry, but in our experience a prototype consists of blank boards and cards printed on computer paper – the best way to start making your game. A hard copy proof is your full, printed game and is used to judge your printer’s quality and material. Again, this can make a great advanced prototype for play-testing, but is pricey for a prototype. Due to the complex process of offset game printing, some of your pieces will be printed digitally. Any component that is digitally printed will not be color accurate.

Freshly updated customer reviews from TrustPilot

Printer’s Marks

Printer’s marks are special marks that are added to your PDF files and to the edge of your parent sheets to assist the offset printing press in proper alignment, trimming, and color values. These printer’s marks are trimmed off once printing is complete.

Color Bars

Color bars, or color control strips, are printed in the trim area of a parent sheet. Press operators use the color bars to check for ink density, overprinting, grey balance, and more. Color bars are so efficient that they can reveal issues with ink hue, rubber blanket, and impression cylinder miscues.

Registration

Registration is the process of precisely lining up cyan, magenta, yellow, and black printing plates so that their overlap produces the full color spectrum. Registration marks (crosshairs) are added to your PDF files and your plates. As printing takes place, the pressman makes sure that both sets of registration marks line up, adjusting their alignment as needed. Once all four colors are printed, the crosshair should be a solid black circle; otherwise, the press operator will know the job isn’t being printed correctly and will make more adjustments. Without registration, your images can appear blurred, as the four colors may not line up and will exhibit the ‘ghosting’ that you often see in newspaper color photos (since the large web presses used to print newspapers frequently have registration issues).

Freshly updated customer reviews from TrustPilot

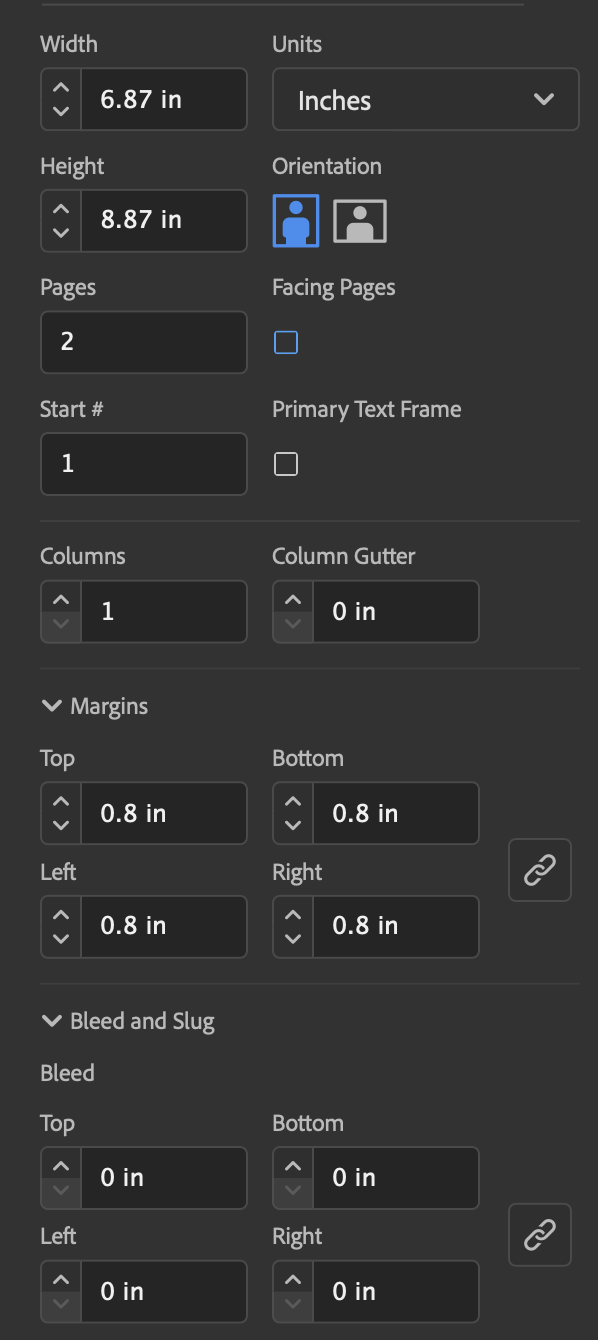

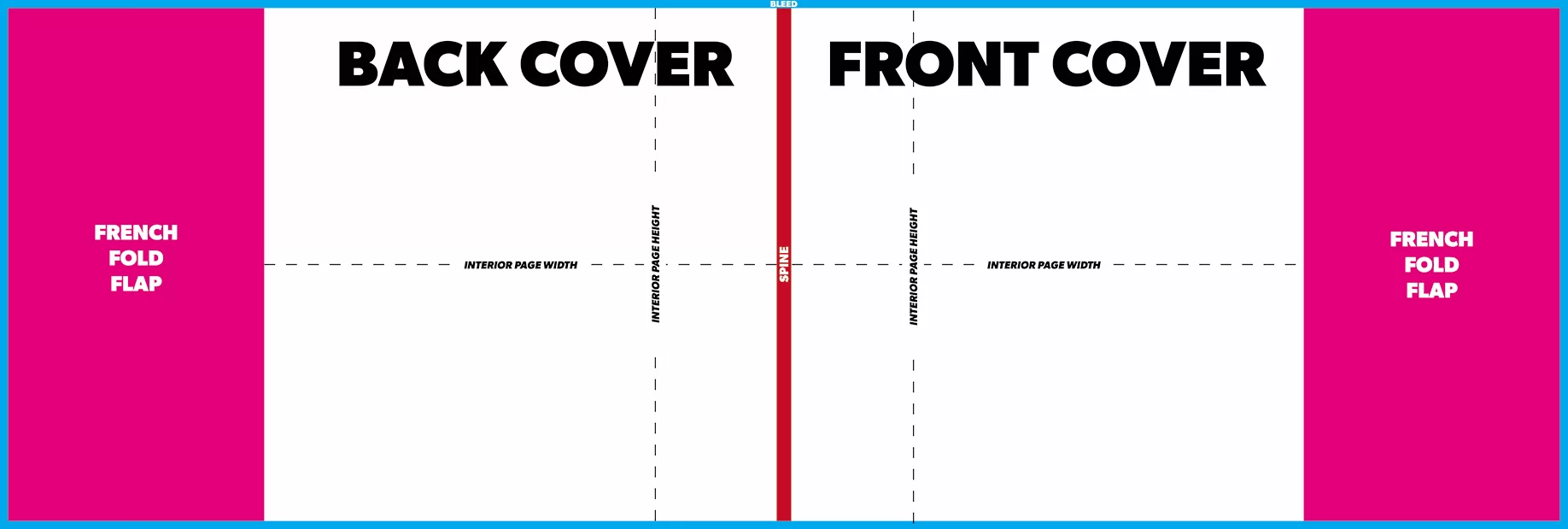

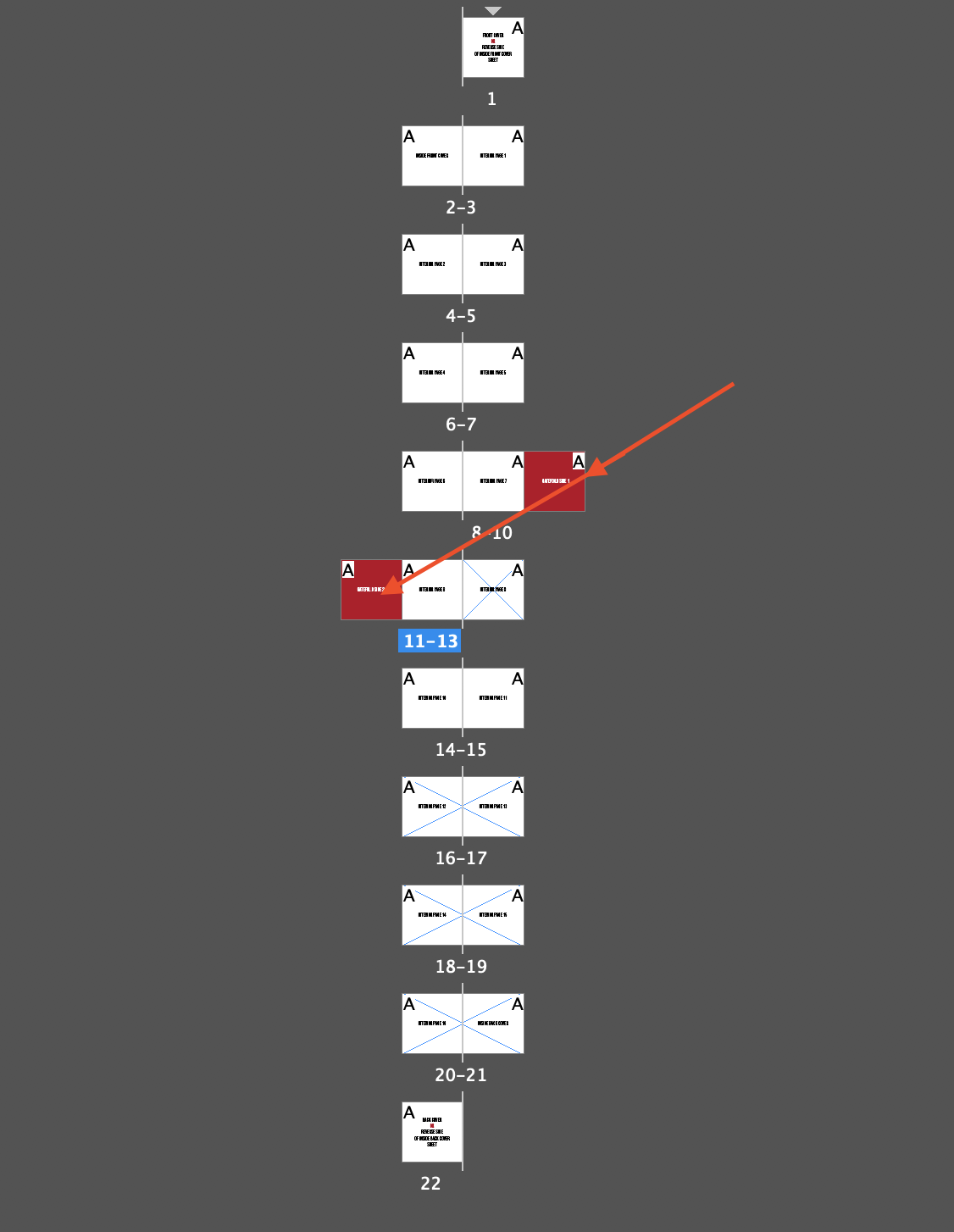

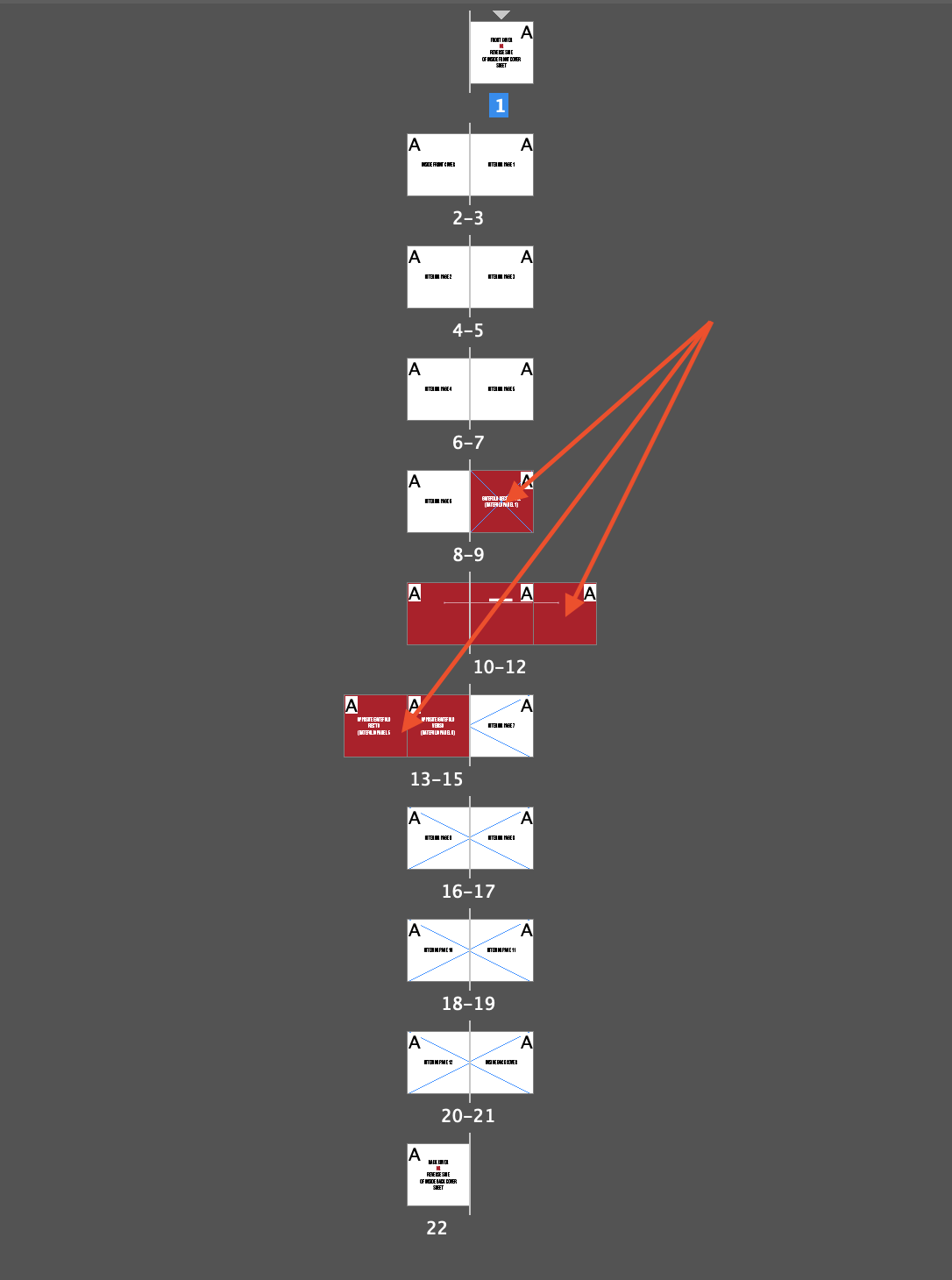

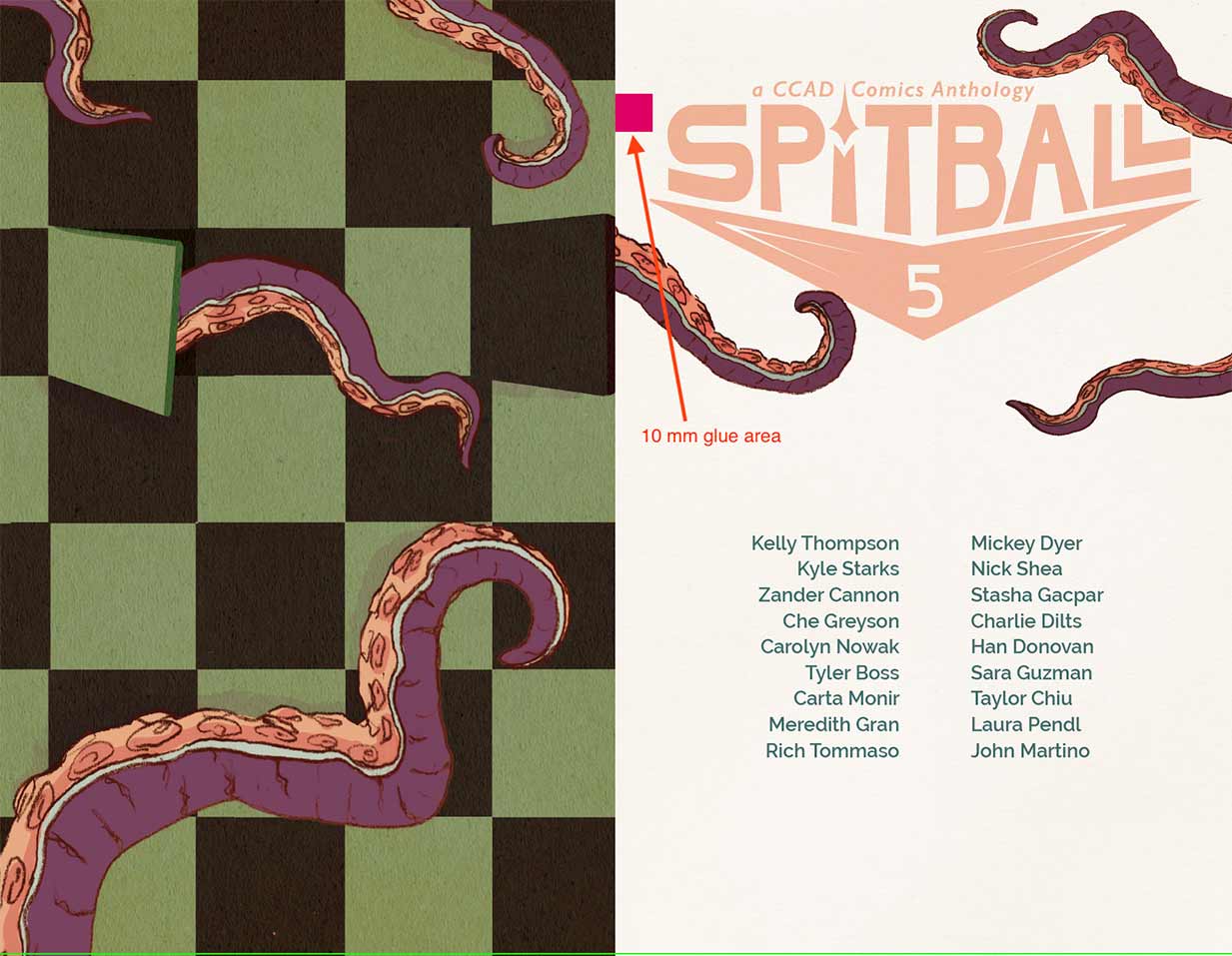

Imposition and Pagination

Imposition is the arrangement of individual pages or cards onto press sheets, also known as parent sheets. Our press operators use imposition software to translate PDF files into a format and layout that can be engraved onto printing plates that will be installed into the offset press.

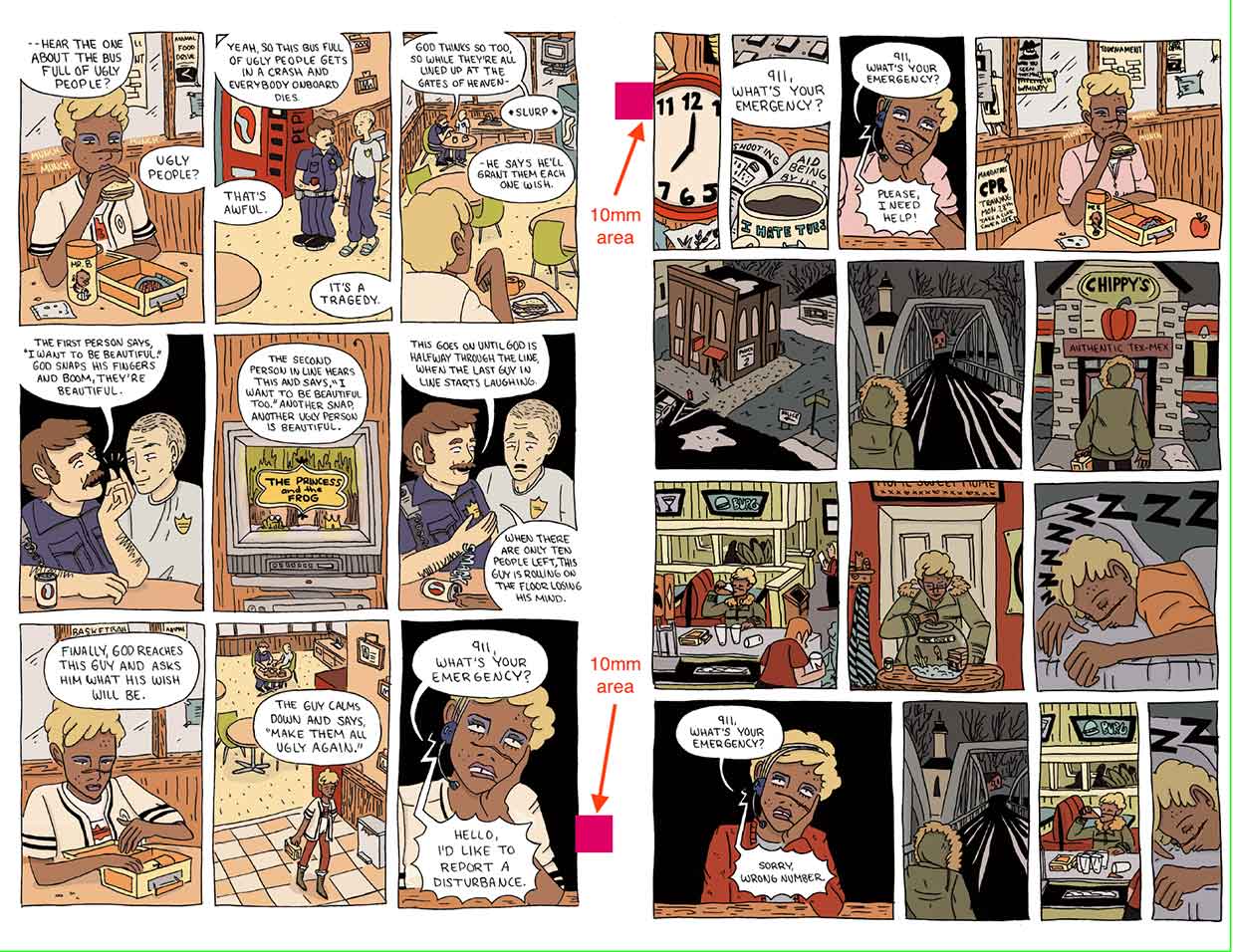

Book Printing Layout

For offset printing, the most common layout has 8 pages per side of a parent sheet, meaning each parent sheet will have 16 total pages when printed on both sides. Small-format projects (6″ x 9″, for example) may have 16 pages per side of a parent sheet, and large-format projects (larger than 9″ x 12″) may only have 4 pages per side. We use a smaller parent sheet size for digital-offset printing, which generally means that fewer pages can fit on one parent sheet. Depending on the size of the project, we can run files at 4-up or 8-up (4 art files per sheet of paper or 8 art files per sheet of paper).

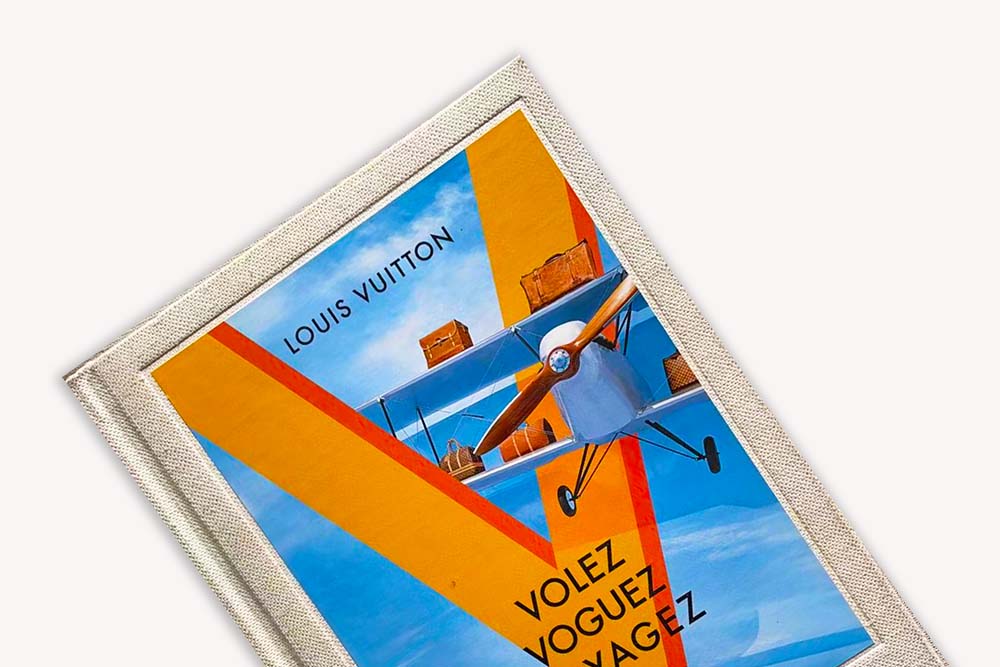

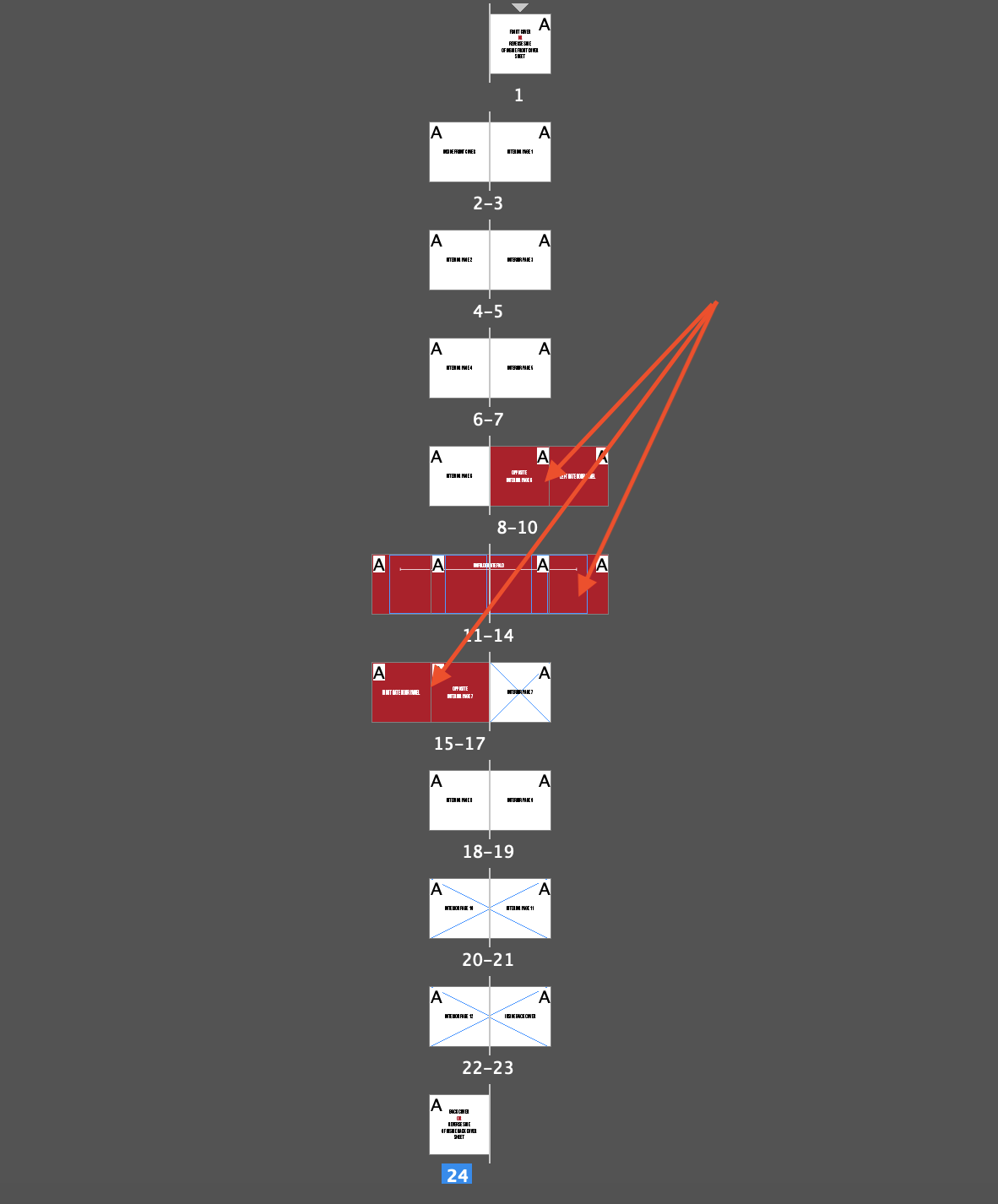

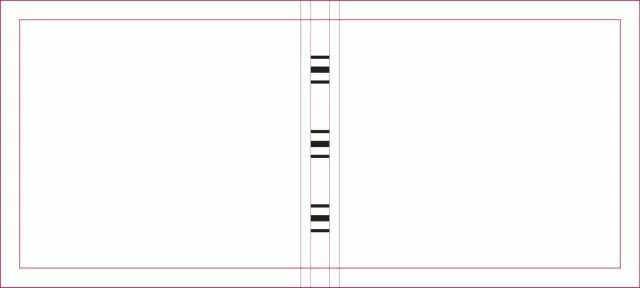

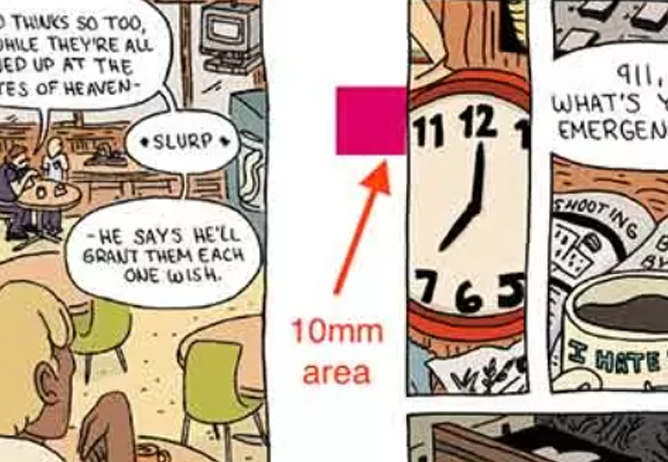

Below, you can see how a typical 16-page section of a book is laid out for offset printing. This parent sheet will be folded to the size of the final project, and this grouping of pages is known as a signature. Don’t worry! You don’t need to submit your art files in this format. PrintNinja will figure out the proper pagination to ensure that all pages are printed, folded, and bound in the correct order.

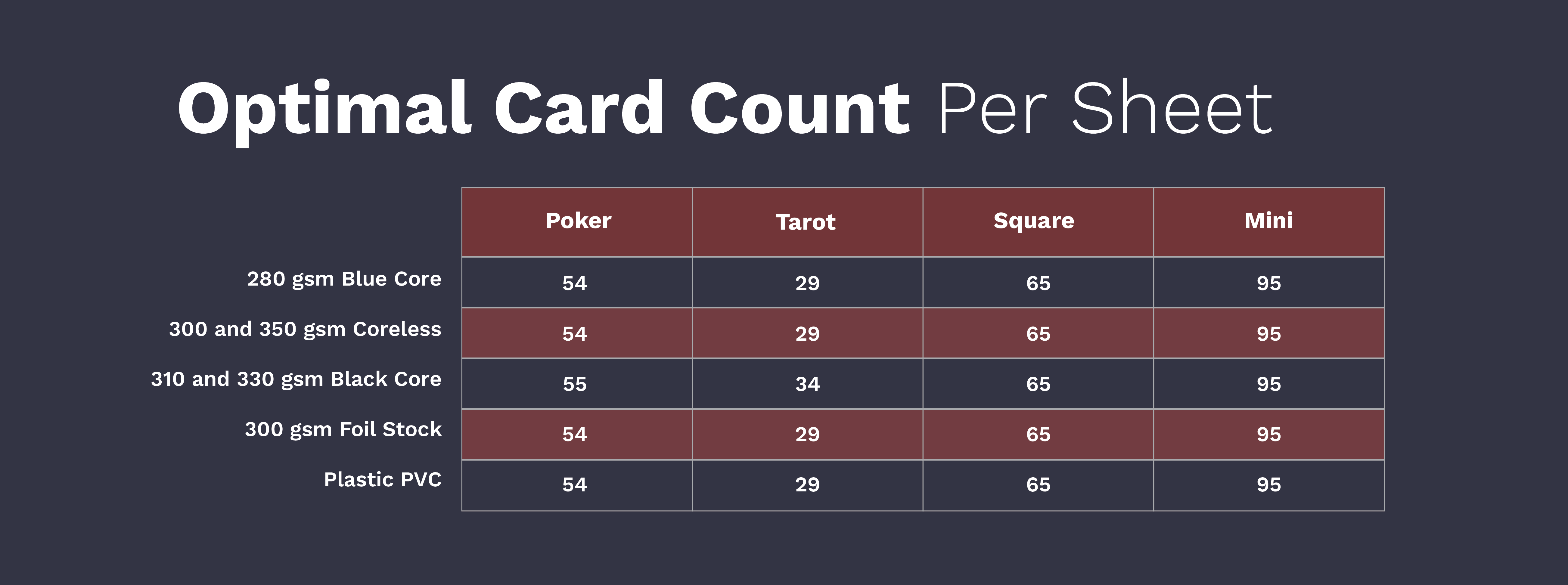

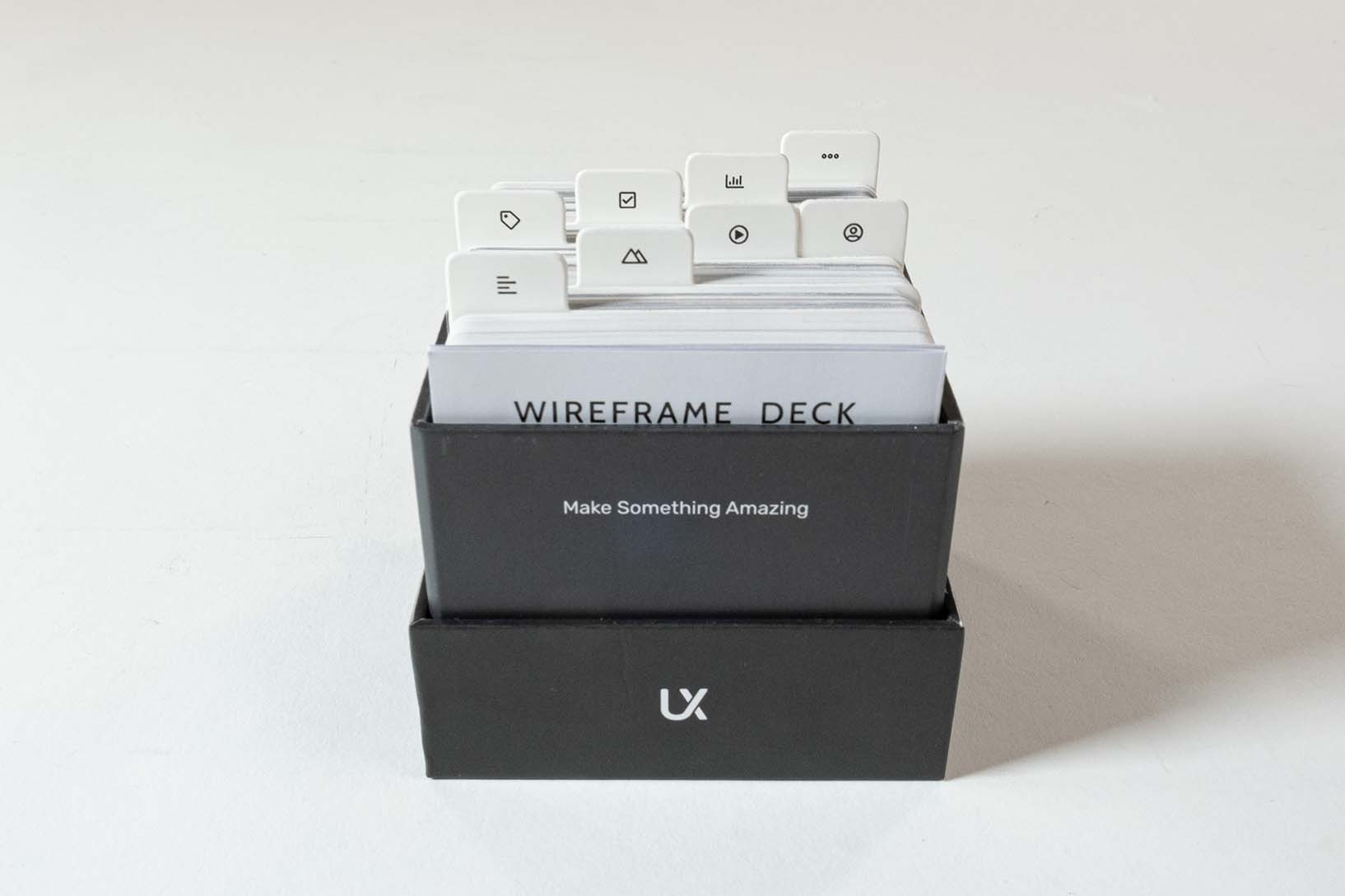

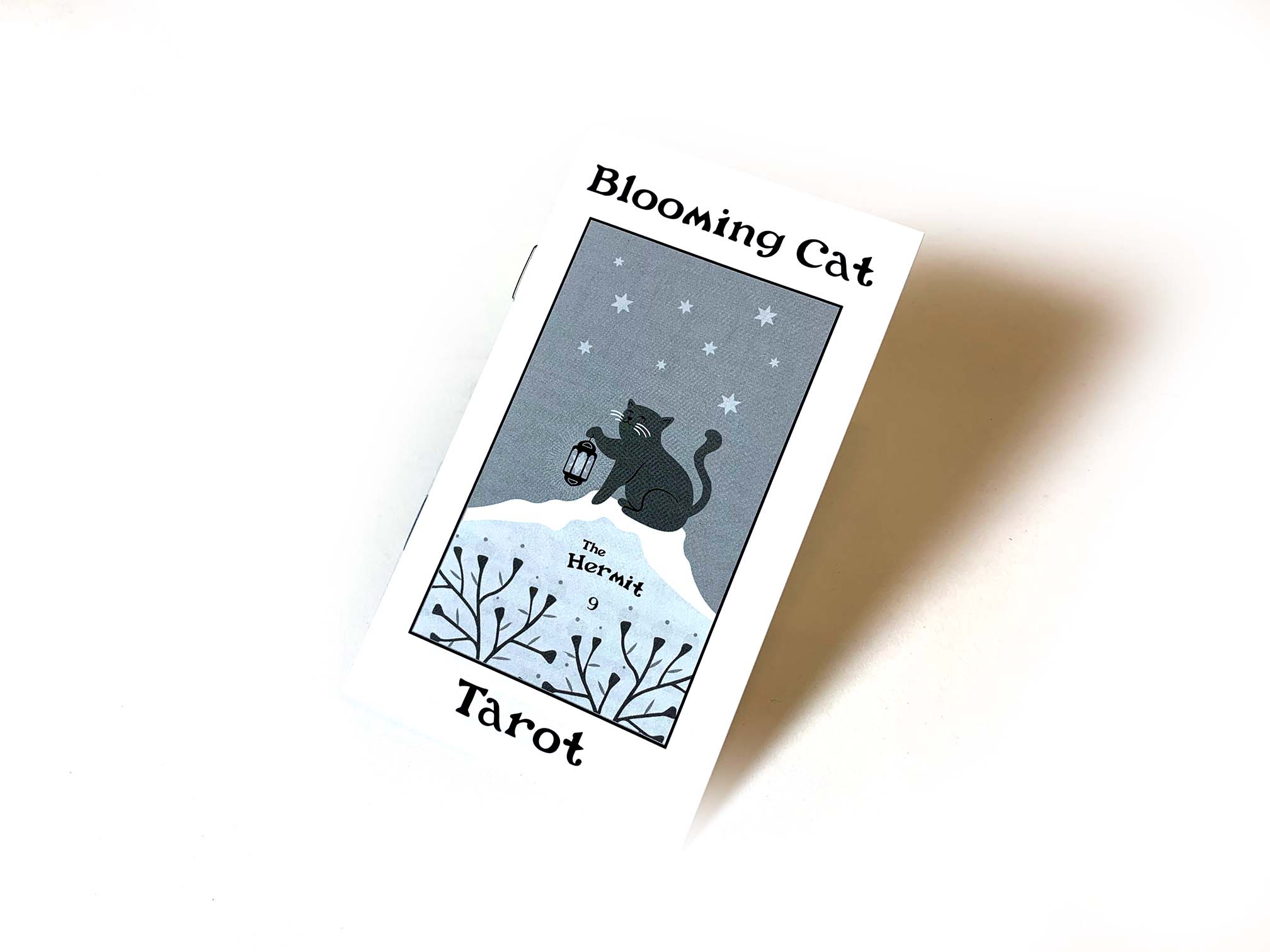

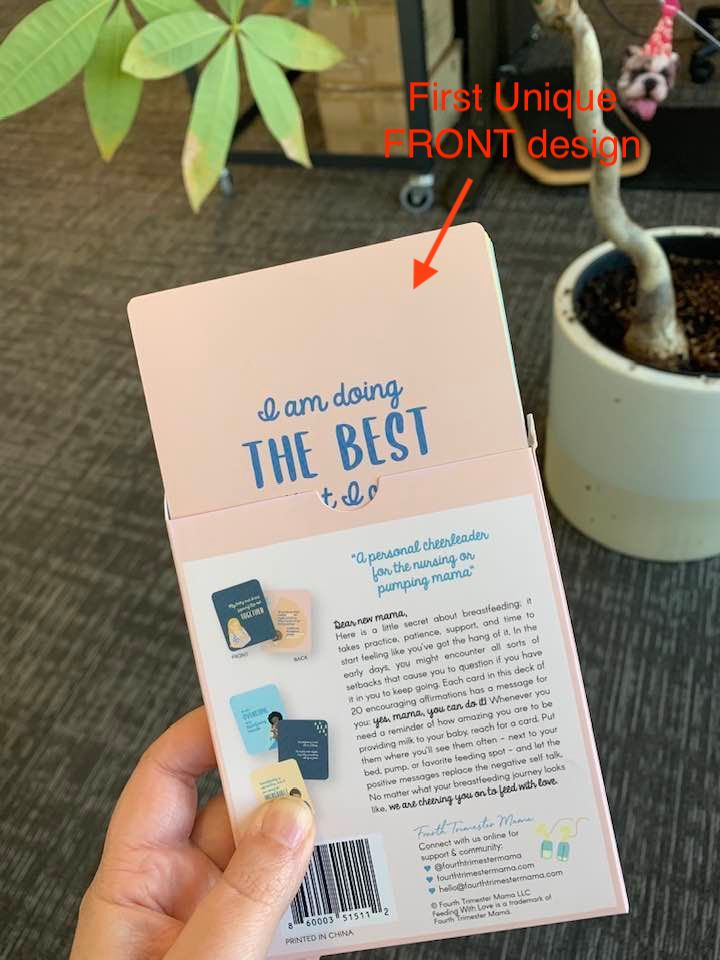

Playing Card Printing Layout

Playing cards are similar to books in that there’s an optimal card count for each card size and card stock. Card stock (Blue Core, Black Core, Coreless) parent sheets come in different sizes, which affect how many cards can fit on one sheet. Of course, different card sizes (Poker, Tarot, Square, Mini) will fit differently on each parent sheet. The smaller your cards, the more you can fit on one sheet.

Press Check & Pagination

After imposition, each full parent sheet is printed with a large-format proof printer. These high-end printers produce reliable colors that press experts use to color-match against offset printed sheets.

The operator will also use this sheet to check for pagination, or the order of pages, by folding the parent sheet to the final product size. This process confirms that all the pages will be printed in the proper order and that they will appear right-side up when bound together. Although most printers use computer systems to automate pagination, sometimes a press operator will override the computer to manually adjust the pagination as needed.

Page Count Explained

For most books, your page count has to be a multiple of four. The easiest way to understand this is to find a piece of paper and fold it in half three times. Each time you make a crease, you increase your page count by four. This folded sheet is how your pages will be inserted and bound into your book as a unit.

There are just a few exceptions to this rule. Board books, spiral bound books, and wire bound books use different binding methods, so they simply require your page count to be a multiple of two.

Freshly updated customer reviews from TrustPilot

Manufacturing Printing Plates

How are printing plates made?

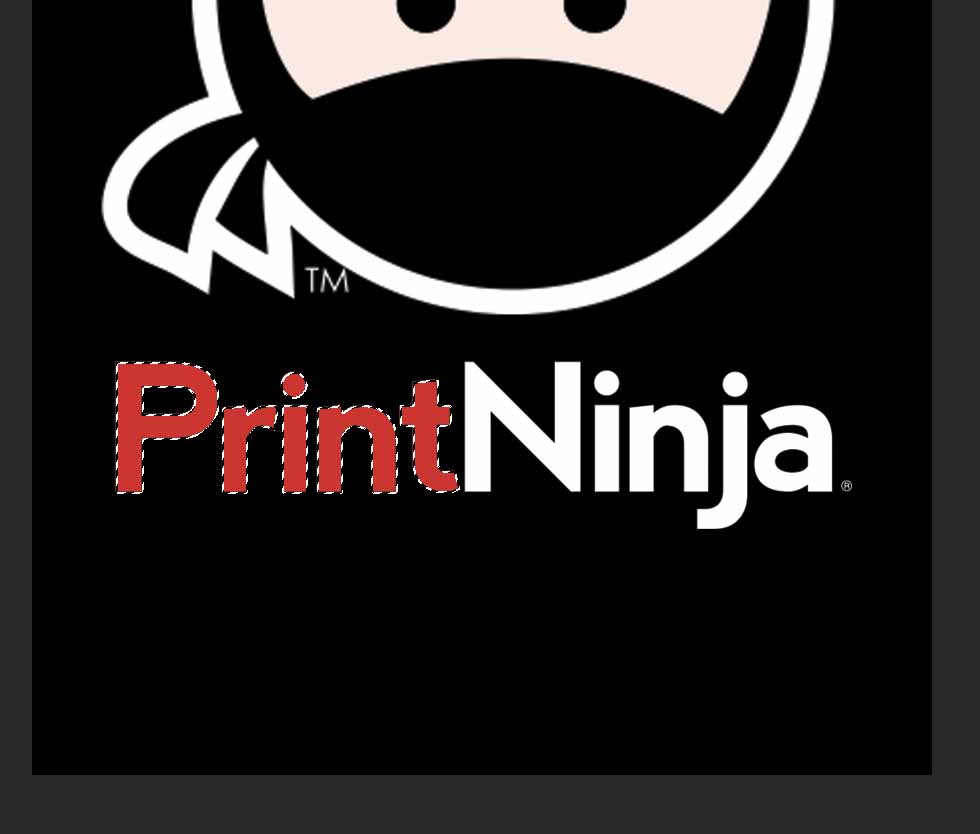

After imposition, each parent-sheet-sized art file is split out into four separate files, one for each color of ink: cyan, magenta, yellow, and black (CMYK). From there, each separated file is laser-engraved onto its own plate to be installed into the printing press.

These thin metal plates are sturdy enough to be used for many thousands of impressions, yet also flexible enough to wrap around a rotating cylinder inside the printing press:

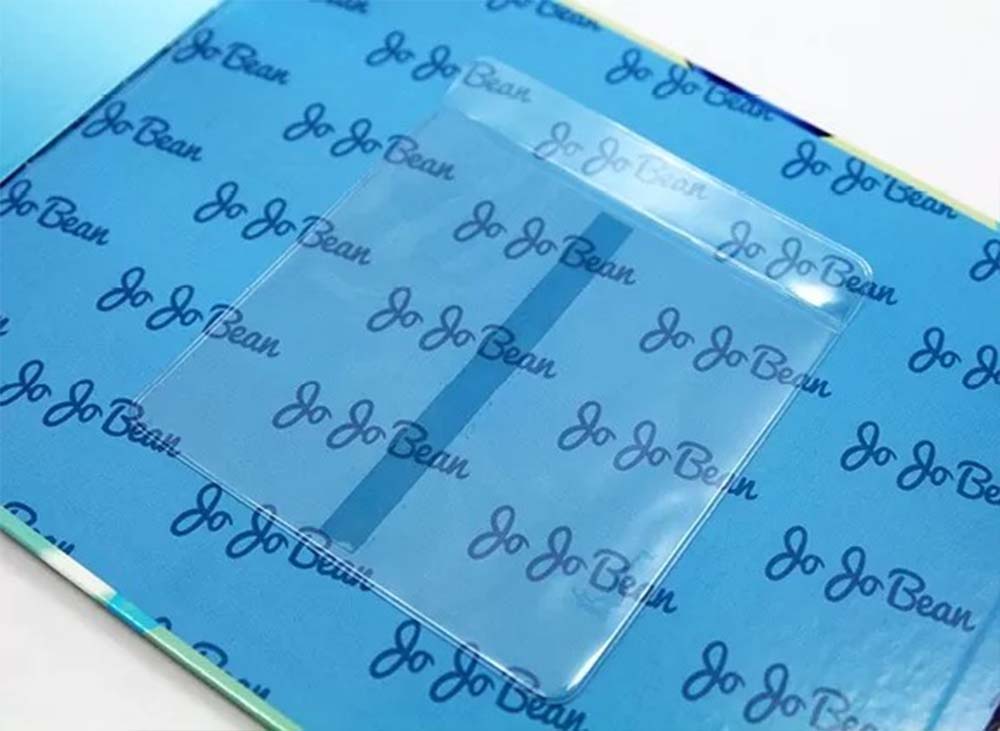

Don’t be fooled by the color: the coating on printing plates is blue, but this has no bearing on the color of ink the plate will apply.

In the past, many printers used a photographic process to create printing plates, but these days most modern print shops use large Computer-To-Plate (CTP) machines like the one pictured here:

First, a coated thermal plate is inserted into the CTP image setter (large compartment to the right in the photo above), where lasers are used to output the image by heating areas of the plate to different degrees depending on how much ink each area should collect. The plate rolls out of the laser compartment and moves through a special cleaning solution that washes away the heated parts of the coating, leaving a negative of the image.

Watch how your plate is rinsed to reveal your images.

Remember, each parent sheet actually needs four plates, one for each color of ink to be applied. Below are four used printing plates that were just uninstalled from the press after being used to print a full-color parent sheet. It can be tricky to see which colors of ink are which due to the underlying blue color of the plates, but from left to right you can see the yellow, magenta, cyan, and black plates used on this job.

Freshly updated customer reviews from TrustPilot

Press

What is a press run, and what does it entail?

Prepress is finally complete. Proofs have been approved, imposition and pagination have been done, and the printing plates have been manufactured. Now it’s time for the next step: the press run. Here, sheets of paper are fed through the press while the plates transfer ink from the rollers to rubber cylinders, and then to the paper itself. This two-step process is why this printing process is called “offset.”

Most offset printing presses function similarly, but the quality of the final product depends on several factors – perhaps most importantly, a certified team of press operators and quality control specialists. That’s why we make sure you’re aware of the quality assurance steps our vendors take: there are many quality control checkpoints throughout the entire process, from file and production prepress to printing and binding. Perhaps the most vital is checking parent sheets as they’re coming off of the press. In our partner facilities in China, press operators will randomly cross-reference printed sheets with a previously printed proof to confirm color accuracy, making sure that quality stays high throughout the entire print run and that the colors and registration aren’t drifting away from where they need to be as the run progresses.

Press Run Chapters:

Freshly updated customer reviews from TrustPilot

Paper and Card Stock

The whole printing process begins with paper. Paper comes in a variety of weights and finishes, and every printing company offers different options depending on their paper suppliers and presses. You’ll find the widest variety of paper options when working with offset printers because operators can calibrate the press based on thickness and coatings.

Parent Sheet Size

Parent sheets are large pre-cut pieces of paper, typically designed to fit 4–16 pages of a project on each side or 55 poker cards. They come in many weights and are often pre-coated with gloss or matte.

One of the major factors in the cost of a printing project is how many parent sheets will be used, which is why certain standard sizes (8.5″ x 11″, 6″ x 9″, 9″ x 12″) and page counts (multiples of 16) are usually the most cost-effective choices since they can maximize the parent sheets used.

Paper Weight

Paper weight refers to a particular thickness of paper stock. There are many different weight classifications, including text, cover, index, bond, bristol, and more, as well as the metric system classification of grams per square meter. When comparing within a specific classification of paper, a lighter weight indicates a thinner paper.

Make sure to include both weight and classification when comparing paper stocks, especially when comparing quotes from different countries. For example, many US printers may give you a quote for “80 lb. cover” which is much heavier than “80 lb. text”. If you’re not sure where to begin, you can always use our industry standards pages to help with your decision.

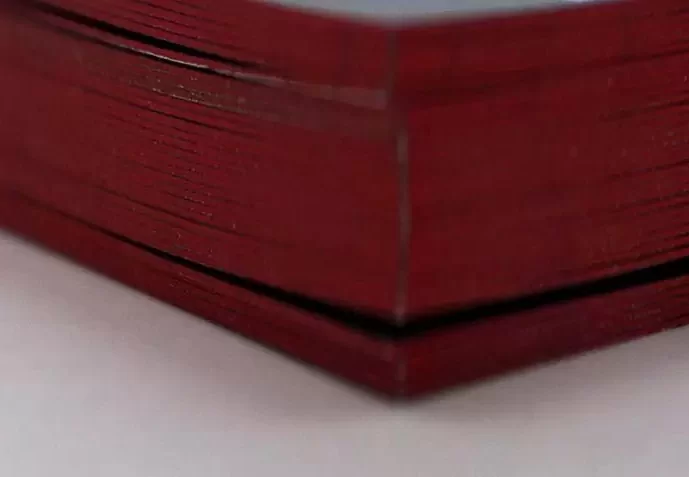

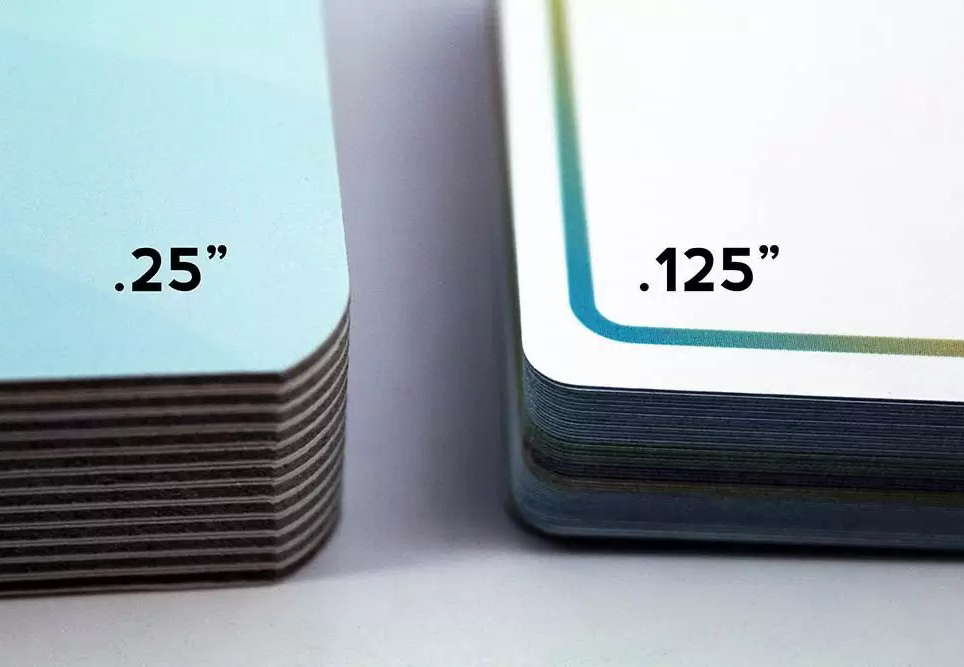

Cardstock

The GSM (grams per square meter) measurement mentioned in the paper weight section above, often applies to playing cardstock. The higher the number (300gsm, 310gsm, 330gsm, 350gsm) the thicker the card stock. Keep in mind that GSM does not always equate to the rigidity of a card. For example, 100lb Cover Linen Card Stock is 270gsm while our 12pt Coreless Stock is 260gsm. The 12pt Coreless stock feels more rigid in your hand, even though the 100lb Cover Linen stock is technically thicker at 270gsm. When selecting a paper weight for your playing cards you need to also consider the core, the material placed in-between the two pieces of paper that make up your card (i.e. 300gsm Blue Core, 330gsm Black Core).

What Does a Card Core Do?

The job of the core is to make your card less transparent and more durable. From lowest quality to highest, the cores range from: coreless, grey, white, blue, and black. Many card printers use different terms to explain the cores, so be wary of the name and request a sample when possible. You can determine a cards core by ripping the card in half — the core color should be visible.

Selecting a Card Core

Most often board game creators will select a coreless cardstock since their cards will not be handled frequently. On the other hand, our card game creators lean towards blue and black core since their games revolve around cards, which are typically held in players’ hands the entire game.

Paper Coating

Coating is applied during the paper manufacturing process. Coating affects the way that inks are absorbed by the paper, making halftone dots and text stay sharp. Any paper weight can have a coating, and which coating to choose is largely a creative decision. Here are the three most popular options:

Freshly updated customer reviews from TrustPilot

Ink

How is printing ink used?

Now that we’ve covered paper, the other main ingredient we need for the offset printing process is ink! Most full-color offset printing uses four colors of ink (cyan, magenta, yellow, and black), applied separately via four separate printing plates, to produce millions of colors. This ink makes its way down from the ink reservoir (known as a fountain) onto the printing plate, then onto the rubber blanket, and finally onto the paper itself. The photo below shows four ink fountains on a 4-color press machine.

Ink Fountain

If you look down at an offset press from above, you’ll see four ink fountains — one for each color of ink. Each of these fountains sits at the top of an assembly containing a cylinder that will hold the printing plate and another that will hold the rubber blanket.

Water Solution

Each fountain also has a reservoir of a water-based liquid known as fountain solution. This water solution is rolled onto the printing plate to repel the ink from the areas that will become white space on paper. Digital offset utilizes the chemistry of water and imaging oil solutions to achieve the same effect.

Roller

The roller distributes ink onto the plate in an even, controlled manner, creating consistent ink coverage for the entire plate.

Freshly updated customer reviews from TrustPilot

Press Setup

How is an offset printing press set up?

PrintNinja’s custom printing includes a detailed setup to achieve the best results in creating your book, calendar, comic, or other product. For your general knowledge and convenience, each step in printing your custom project is detailed below.

Cleaning the Press

First things first, the press must be cleaned from its last use. On a traditional offset press, all printing plates must be uninstalled, and in the case of a digital offset printer, the printing image plate is cleaned with imaging oil. In a traditional offset press, all cylinders, fountains and rollers are cleaned after every press run to ensure the next parent sheet has a fresh setup. It is important these three pieces are clean so the alignment is not thrown off by dirt.

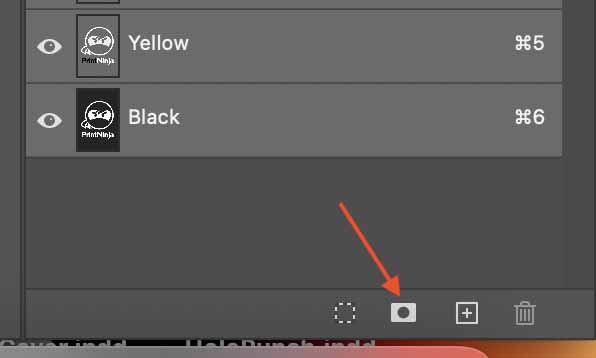

Installing the Plates

Four plates are clamped onto cylinders inside the press. One plate is used for each color: cyan, magenta, yellow, and black (CMYK). Each time a new parent sheet needs printing, four new plates must be mounted into the press. The cost and time involved in these installations is what makes offset printing impractical for small runs.

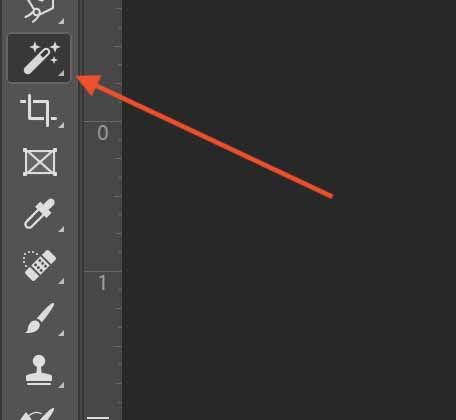

Calibrating the Press

The press operator adjusts the press’ output using calibration software. The press operator will adjust the color control using levels, curves, and other tools to produce the right color density. Paper thickness and coating are calculated in the software, with the absorption of ink taken into account.

The press runs at a slow speed so the initial sheets can be carefully checked for alignment and color against the press operator’s proof. The operator can then make adjustments to the press as needed. Once there is a proper amount of ink density on the paper, the press speed is increased to full production.

Ready to get started?

PrintNinja can print books, playing cards, board games, calendars, puzzles, and more. Whether you’re ready to print or just starting to budget your project, it’s always a great time to check out our instant price calculator. You can even lock in your price for 90 days!

See Project TypesFreshly updated customer reviews from TrustPilot

Press Check

What is a press check?

Most offset printing presses function similarly, but the quality of the final product depends on a number of factors – perhaps most importantly, a certified team of press operators and quality control specialists. Most printing facilities will have a Quality Assurance department responsible for inspecting all printed parent sheets during the press run, monitoring the final product for defects, and flagging any issues early on in order to deter waste.

On-Site Press Check

There are many quality control checkpoints throughout the entire process, from file and production prepress to printing and binding. Perhaps the most vital is checking parent sheets as they’re coming off of the press.

Press operators will randomly cross-reference printed sheets with a previously printed proof to confirm color accuracy, making sure that quality stays high throughout the entire print run and that the colors and registration aren’t drifting away from where they need to be as the run progresses.

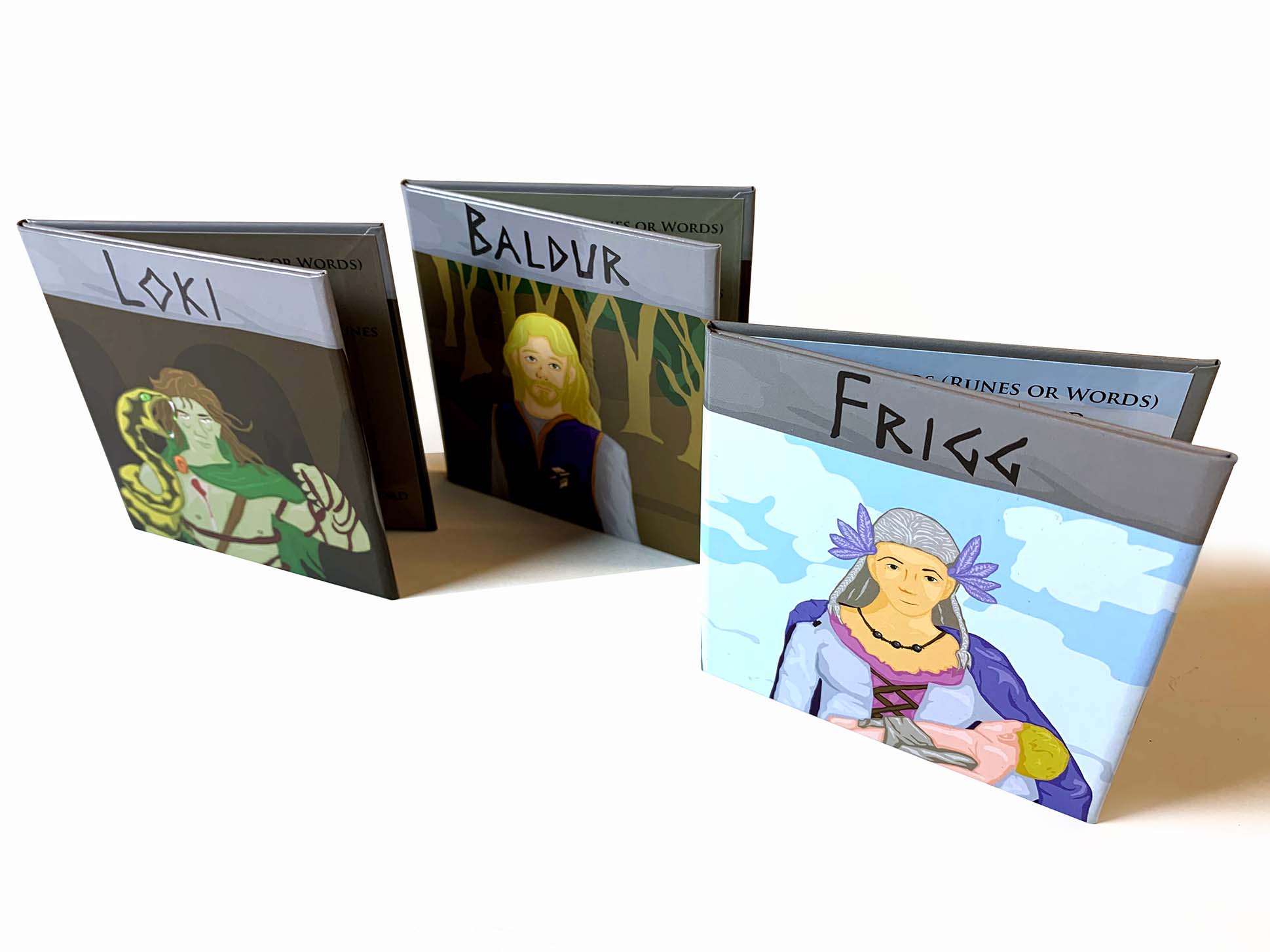

Game Quality Control

Printed game pieces (game boards, cards, tokens, etc.) follow the same quality control measures as books, from prepress to pulling printed sheets off the press.

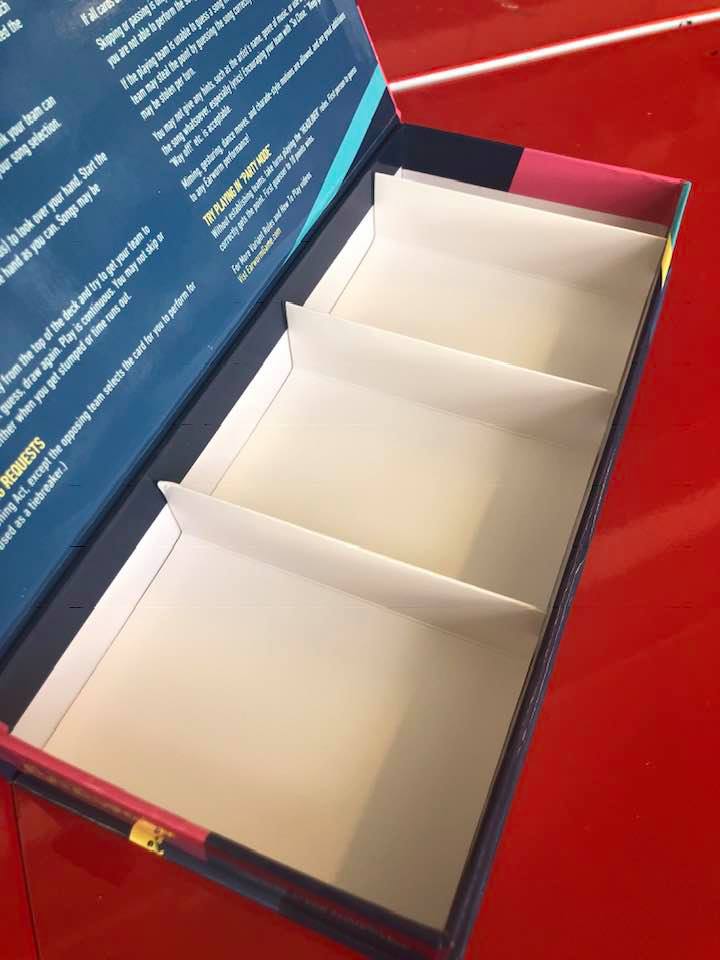

Card game assembly has a few extra steps to ensure consistency. Operators will insert blank pages in between the full printed card game sheets. When blank cards appear, this signals to operators that the deck they are assembling is ending and a new deck is starting. Each deck, once assembled in its packaging, is then weighed to make sure a card is not missing — or, vice versa, that there’s no extra card.

Game pieces we use have passed safety tests. However, if you need paperwork to present to a retailer or distributor that proves your game is safe to sell, then you’ll have to re-run the safety test on your specific game as a whole.

Freshly updated customer reviews from TrustPilot

Cylinders

What are the cylinders used in the printing process and how do they work?

If you look inside the four compartments of the press that hold the ink fountains, you will see something similar to the diagram at the right. Each of those four assemblies is made up of many moving cylinders which are intrinsic to the offset, or lithographic, printing process.

Plate Cylinder

The printing plate – embedded with your file images – is wrapped around the plate cylinder and rotates while water and ink are distributed onto its surface. The plate transfers ink to the rubber blanket, which is wrapped around the offset cylinder.

Rubber Blanket / Offset Cylinder

The offset cylinder is home to the rubber blanket that receives ink from the plate above. This cylinder rotates until the rubber blanket makes contact with a parent sheet moving along the conveyor belt, transferring the ink onto it.

Impression Cylinder

The impression cylinder sits directly underneath the rubber blanket and applies pressure to the paper – moving in between both cylinders – while the paper absorbs ink from the blanket at the same time.

Inside the Press

This is the inside of one press compartment. The top cylinder is the plate that has already been rolled with water and ink from above. The plate rotates and transfers ink to the rubber blanket, the blue cylinder. The final cylinder on the bottom, the impression cylinder, applies pressure to the paper as it passes under the blanket.

Freshly updated customer reviews from TrustPilot

Printing

What happens in the printing process?

We’ve met all of the pieces: the plates, the paper, the ink, and the cylinders. The press has been cleaned and calibrated, and the plates have been installed. Now it’s time to see a 4-color sheet-fed offset press in action printing 8 pages of a real project! Each parent sheet zips through and is printed with four colors of ink all in a row, coming out the other end fully printed.

As you can see, this part of the printing process happens very quickly — but don’t worry, quality assurance is still in place during this step. Most printing facilities will have a Quality Assurance department responsible for inspecting all printed parent sheets during the press run, monitoring the final product for defects, and flagging any issues early on in order to deter waste. The quality control team follows the standards set by the printing facility, who ultimately decides the quality the product is required to meet. These Quality Assurance experts will sign off on color, bindery, and press runs by testing your product at random during different steps of the process.

Watch parent sheets go from blank to fully printed in a matter of seconds in our international facility in the video below:

Freshly updated customer reviews from TrustPilot

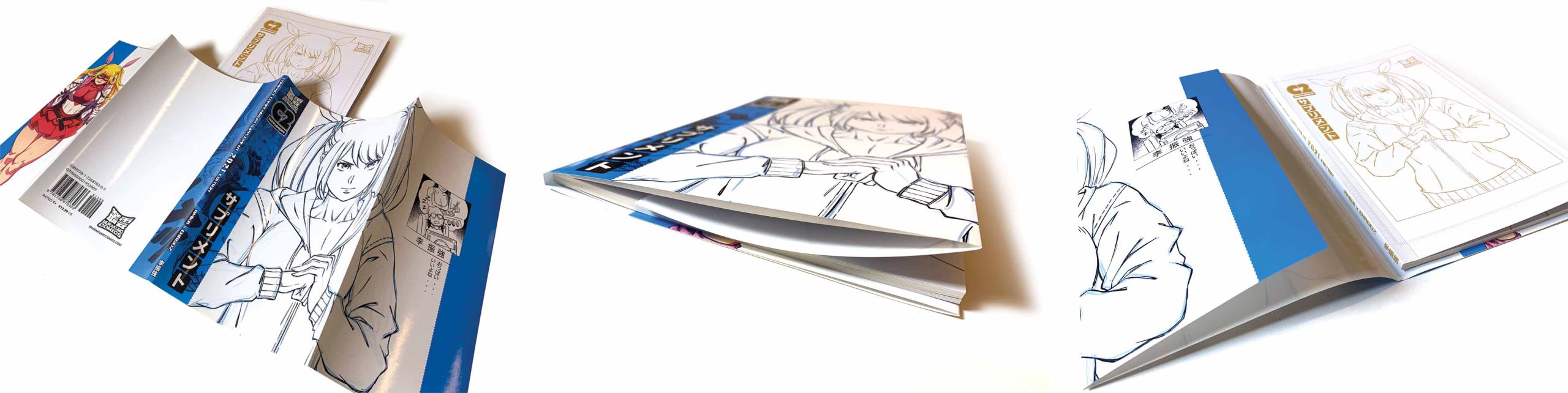

Post-Press

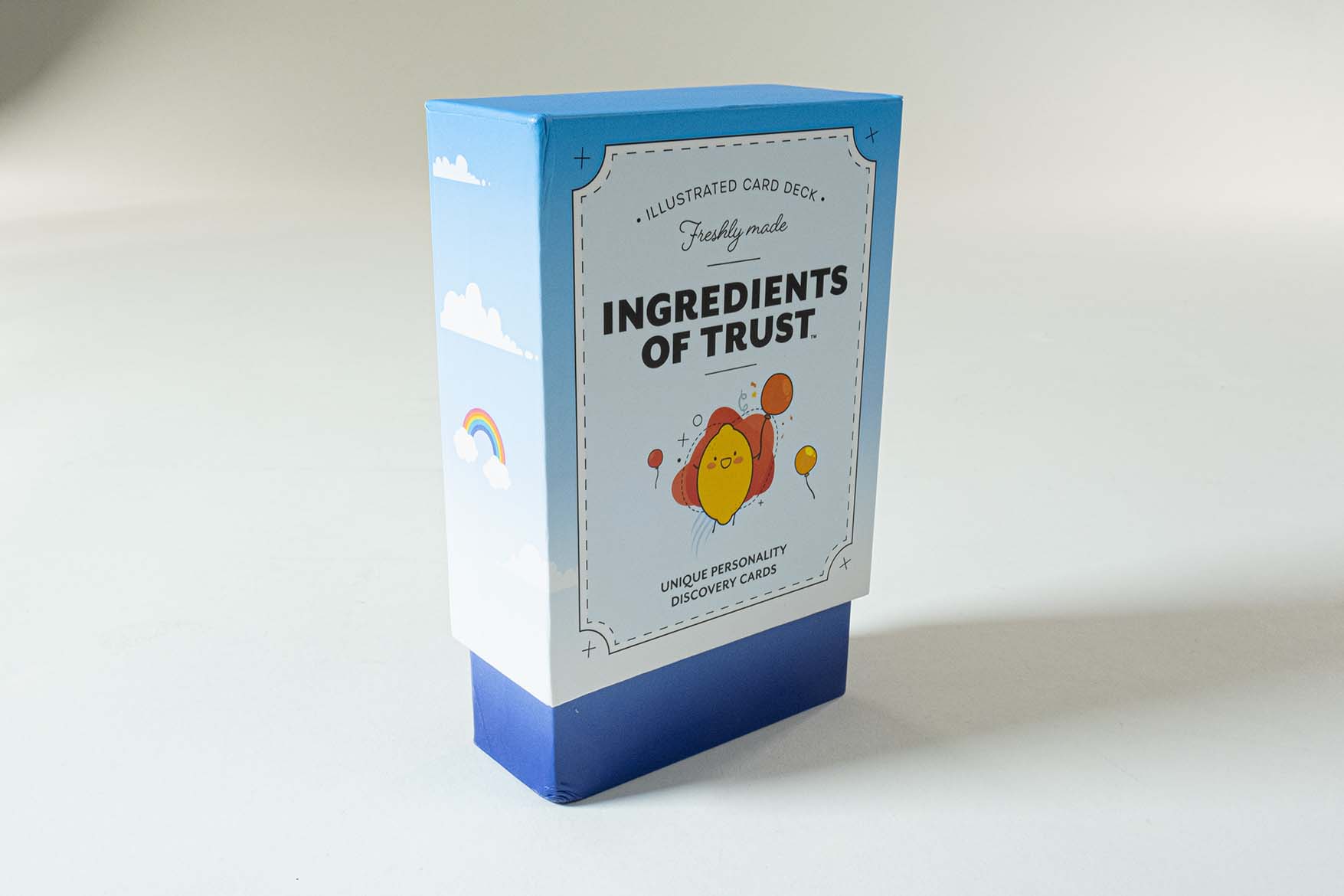

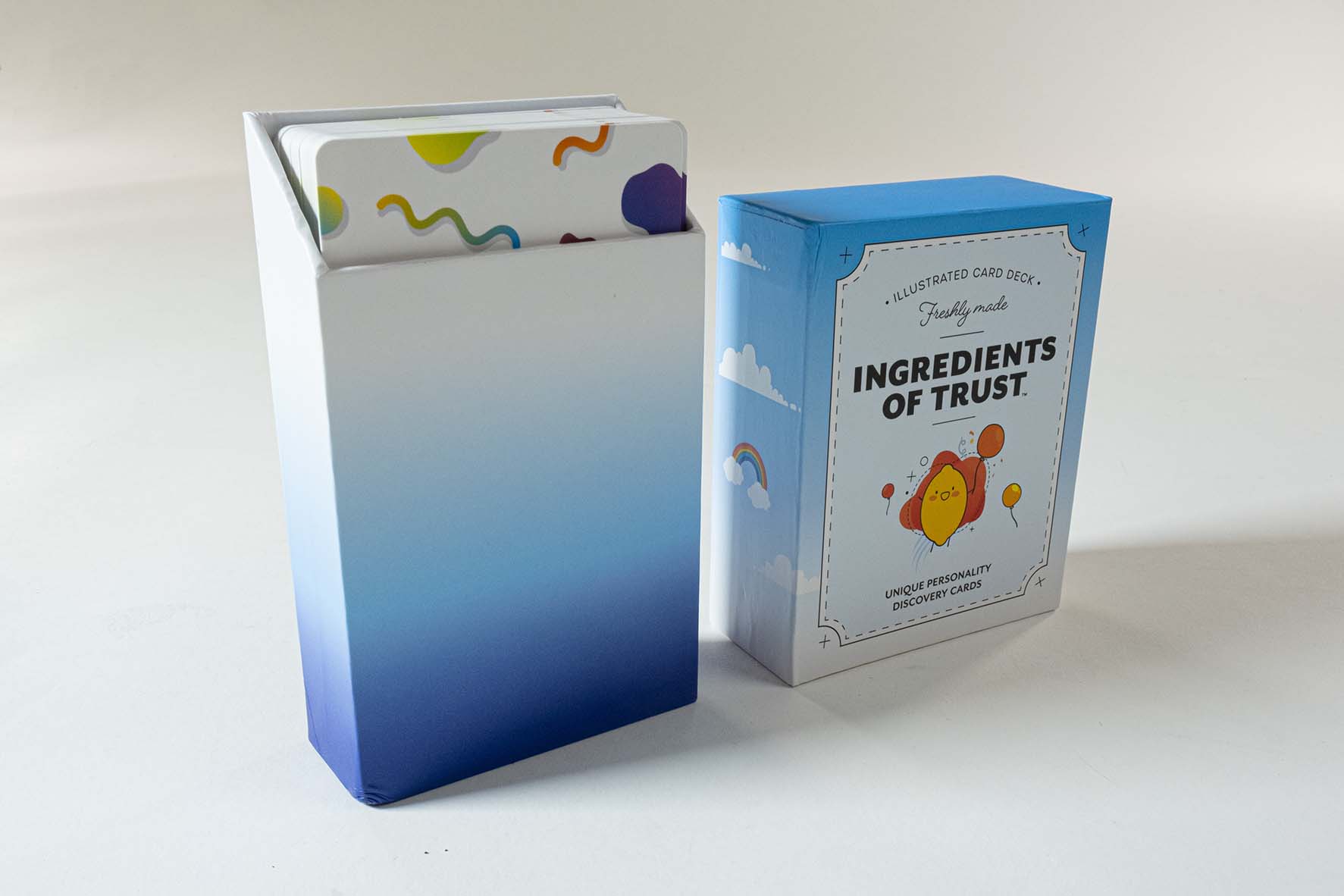

Post-press is everything that takes place after your pages have been printed on parent sheets – and it turns out that “everything” is quite a bit! Books are folded, cut, and bound into your final project before they are ready to be shipped to your front doorstep. For the prepress of board and card games, cards get trimmed, smoothed, and rounded; game boxes are printed and constructed, and then all the components are assembled and packaged to create your final product. That’s a lot of things that happen once the printing process is done!

The following articles will teach you more about just what happens in post-press. You’ll learn about folding signatures, collation sorting, and cover paper finishing. You’ll also learn about on-site quality assurance, book drying methods, and card game production. Read on to become a post-press pro! Of course, if you have any more questions about the post-press process, feel free to contact us — we’re always happy to take questions about what happens after the prepress and press stages of your printed project’s life, but before you receive your final product.

Post-Press Chapters:

Freshly updated customer reviews from TrustPilot

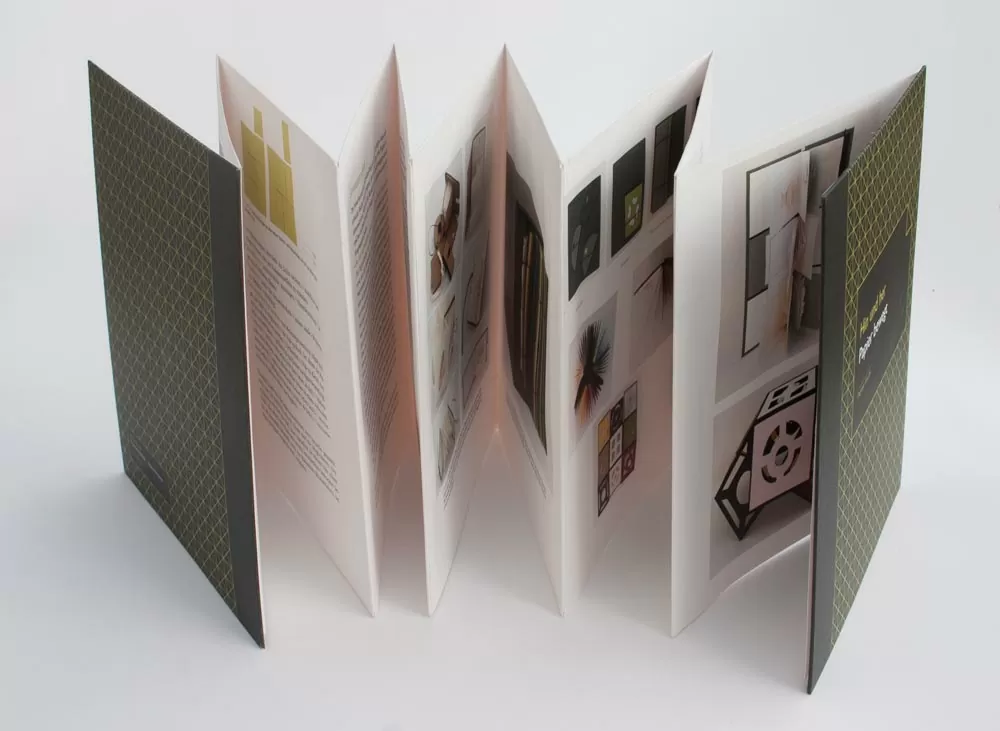

Folding Signatures

This article will teach you about folding signatures and how they are involved in the offset printing process.

Once the printing is complete, the stacks of fully-printed and dried parent sheets are taken to be folded by the folding machine. Each parent sheet zooms through the machine one at a time entering into gates that are set to the proper fold size. A final fold is applied by a heavy arm – this is called the knife fold – which applies immense pressure on the fold line. The final project rolls out of the machine as a “signature.” The majority of projects are folded by these machines, although extremely large projects or those with unique requirements may occasionally be required to be folded by hand.

Watch parent sheets fly through a folding machine and finish as a signature:

Signatures

The folded groups of pages that emerge from the folding machine are called signatures. Most projects have signatures of 16 pages (8 pages on each side of the parent sheet), but projects 6″ x 9″ or smaller may have signatures of 32 pages, and projects larger than 9″ x 12″ may only have 8 pages per signature.

Freshly updated customer reviews from TrustPilot

Collation/Sorting

The collation process starts with parent sheets being folded into signatures.

Parent sheets are large pre-cut pieces of paper, typically designed to fit 4-16 pages of a project on each side or 55 poker cards. They come in many weights and are often pre-coated with gloss or matte coating. One of the major factors in the cost of a printing project is how many parent sheets will be used, which is why certain standard sizes (8.5″x11″, 6″x9″, 9″x12″) and page counts (multiples of 16) are usually the most cost-effective choices since they can maximize the parent sheets used.

Once the printing is complete, the stacks of fully-printed and dried parent sheets are taken to be folded by the folding machine. Each parent sheet zooms through the machine one at a time entering into gates that are set to the proper fold size. A final fold is applied by a heavy arm, called the knife fold, that applies pressure on the fold line. The final project rolls out of the machine as a signature. The majority of projects are folded by these machines, although extremely large projects or those with unique requirements may occasionally be folded by hand.

There may be 1 or dozens of folded signatures that have to be gathered and bound for the final product. Once all the folding is complete the signatures are sent along for collation.

The collator stacks the signatures into the appropriate page order, and they are prepared for final binding. Based on your binding method, this will be either stapled (saddle stitching) or sewn (smyth sewing for perfect binding and case binding). The resulting new stack of ordered signatures is now called the book blocks.

Finally, the stacks of signatures are taken to the collation machine, which collates the separate signatures into their proper page order. The resulting new stacks of ordered signatures are now called book blocks.

Watch the Collation machine stack signatures in page order to make book blocks.

Collation machines like the one pictured below are large enough to handle books with many hundreds of pages, but books with only two or three signatures can also be collated by hand.

Freshly updated customer reviews from TrustPilot

Finish

This article will explain how finish is applied to your cover paper.

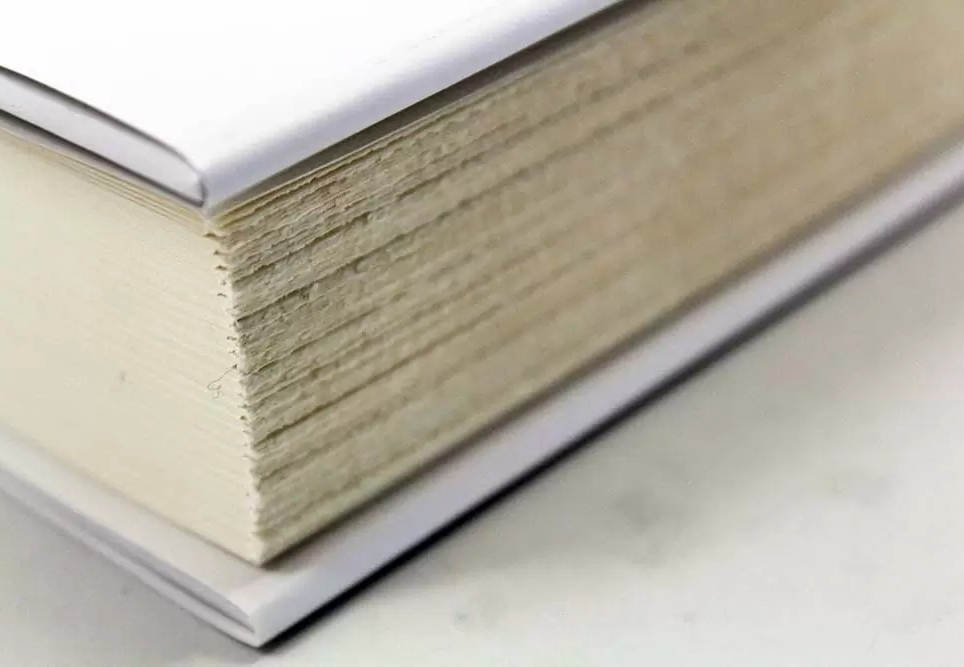

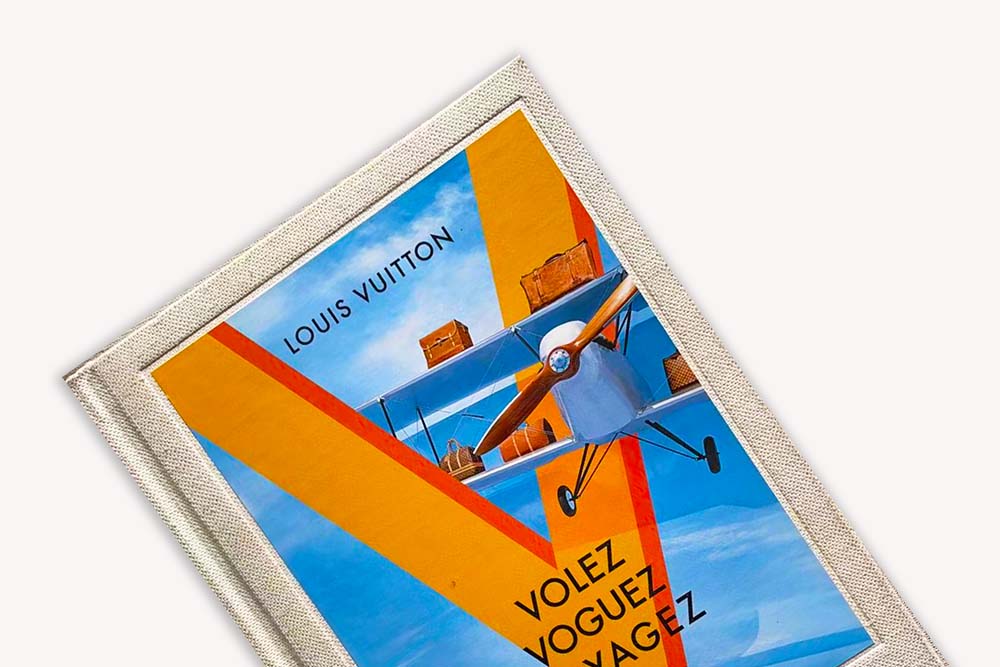

The printing process is almost complete. Your book block is now finally ready to be bound, but before binding can happen, the parent sheet that will become your cover needs to have a finish applied to protect it. Finishes can be gloss (high-shine) or matte (low-shine), and come in two distinct types: varnish and lamination.

A varnish is a liquid finish applied on the printing press to your cover paper following the same process as if it were an ink. The varnish style usually matches the coating of your paper (gloss or matte) and protects the ink on your cover. If you choose matte varnish, you can add spot UV to make select parts of your cover matte.

Lamination is the most protective card finish. Lamination is a thin polypropylene film that is applied after the printing process is complete. As seen in the video at the bottom of this page, a lamination machine glues a roll of film onto the printed parent sheet to produce the desired effect.

On rare occasion, you may opt to skip the cover finish. This provides a raw look and feel, but it’s important to note that it provides no protection, leaving your cover more susceptible to damage. If you want a matte finish, we recommend adding a matte varnish instead of opting to skip the cover finish.

Watch a matte lamination finish being applied to cover paper

Freshly updated customer reviews from TrustPilot

Binding Process

This article includes links that will teach you more about the binding process and the difference in binding styles.

The pieces are all in place. The body pages are folded into a book block, and the cover page has had its specialty finish applied. At this point in your project’s lifespan, we’re finally ready to enter the binding process.

Depending on which binding method you have chosen, binding can be as simple as adding a couple of staples, or it can be a complex process involving sewing machines, gluing machines, hardcover cases, and more. There are three popular binding methods: saddle-stitched (stapled), perfect (softcover), or casebound (hardcover). Each of these methods has it’s own pros and cons. Read on to learn the difference in process between each binding method – the more you know about each one, the better you’ll be able to determine which one is right for your printing project with PrintNinja.

There are also other methods of binding such as spiral binding, wire binding, and a special process for board books. For more information on these less common binding types visit our advanced concepts section.

Freshly updated customer reviews from TrustPilot

Saddle-Stitched Binding

This article will teach you about the saddle-stitch binding process and how it impacts your printed project.

Saddle stitching is definitely the simplest form of binding: two staples are inserted into the spine, holding all of the pages together. It’s a much more straightforward process than hardcover/casebound or perfect-bound/softcover book binding!

As the first step in the process, the cover and book block are collated, with signatures placed one inside the other. Most saddle-stitched projects contain 3 or fewer signatures so that there aren’t more pages than the staples can handle – this is why saddle-stitching is an especially popular binding method for comic books: they have fewer pages than, say, a novel.

Next, the collated pages are put through a stitching machine for stapling. The pages are draped across either side of a “saddle” – hence “saddle-stitched” – belt that runs along the entire machine, and the V-shaped belt helps align all the pages at the central fold for a symmetric binding. The project then moves down the line and staples are inserted at the crease.

Finally, the stapled project is trimmed down to its final size in a guillotine, leaving you with a great looking saddle-stitched project.

Freshly updated customer reviews from TrustPilot

Perfect (Softcover) Binding

The perfect binding process, commonly referred to as softcover binding, results in a book with a glued binding and a squared-off spine.

Smyth Sewing

PrintNinja’s perfect binding process, the collated signatures of the book block are sewn together using the smyth sewing technique. Smyth sewing uses thread to first sew through the folds of each signature and then sew the entire group of signatures (book block) together, resulting in a durable binding that can be opened relatively wide – a great option if you have any pages with continuous spreads.

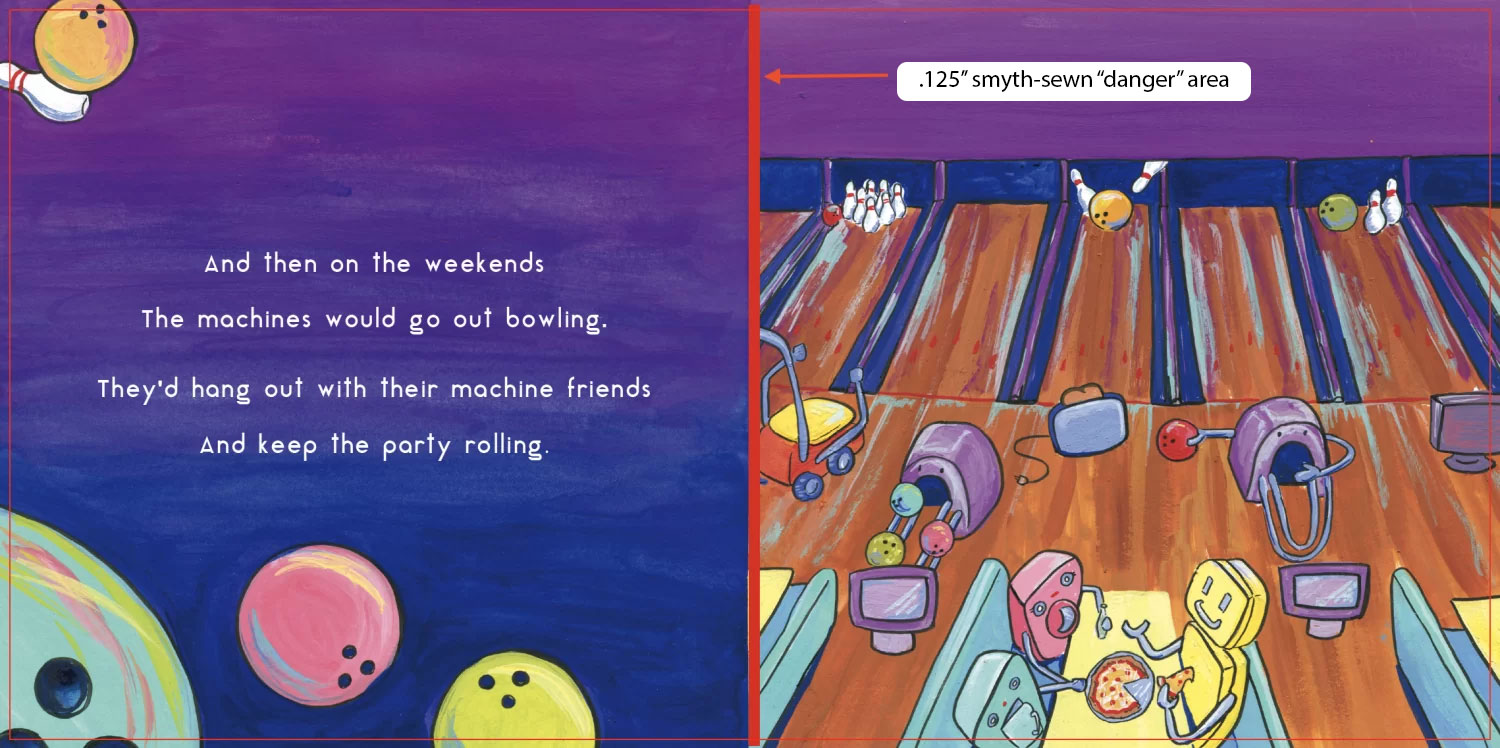

Note

Traditional perfect binding involves cutting the signatures off at the fold instead of sewing them, resulting in a much less durable binding, with much more content lost in the gutter between pages

Gluing

Next, a tech will place the sewn book block into a clamp that tightly holds the body together while it moves through the binding process. First, glue is applied to the spine and run through a heating process, after which the cover is wrapped around the book block.

Trimming

Finally, the bound books are trimmed down to size using a special cutting machine that trims all 3 edges in the same process.

Watch a short clip of softcover books being trimmed in our international facility

Freshly updated customer reviews from TrustPilot

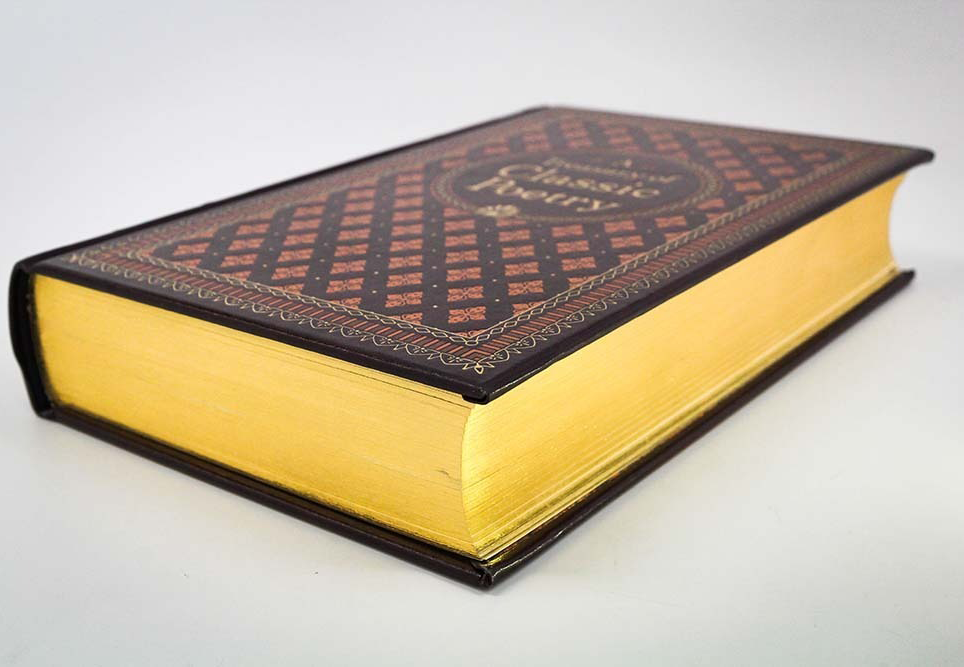

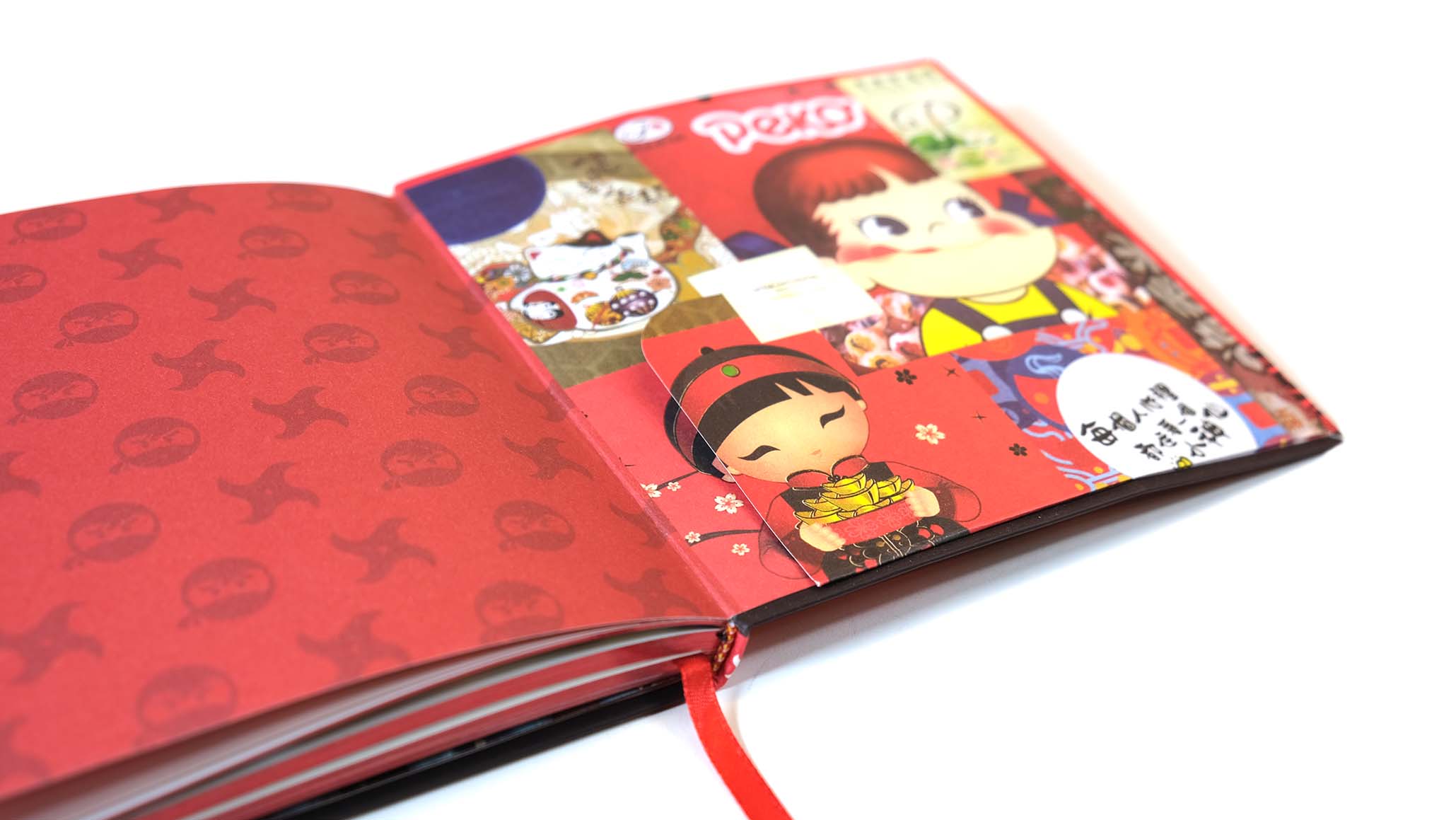

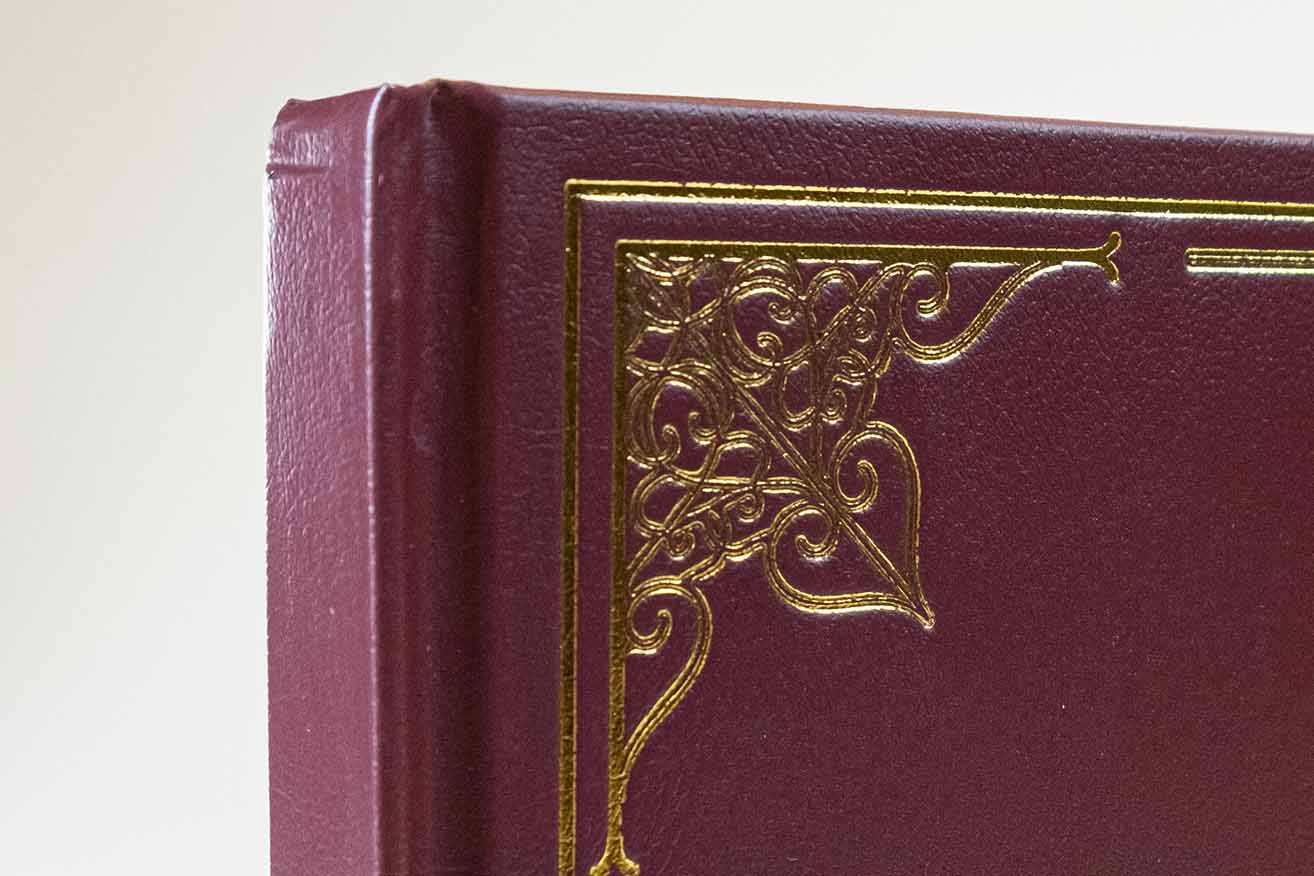

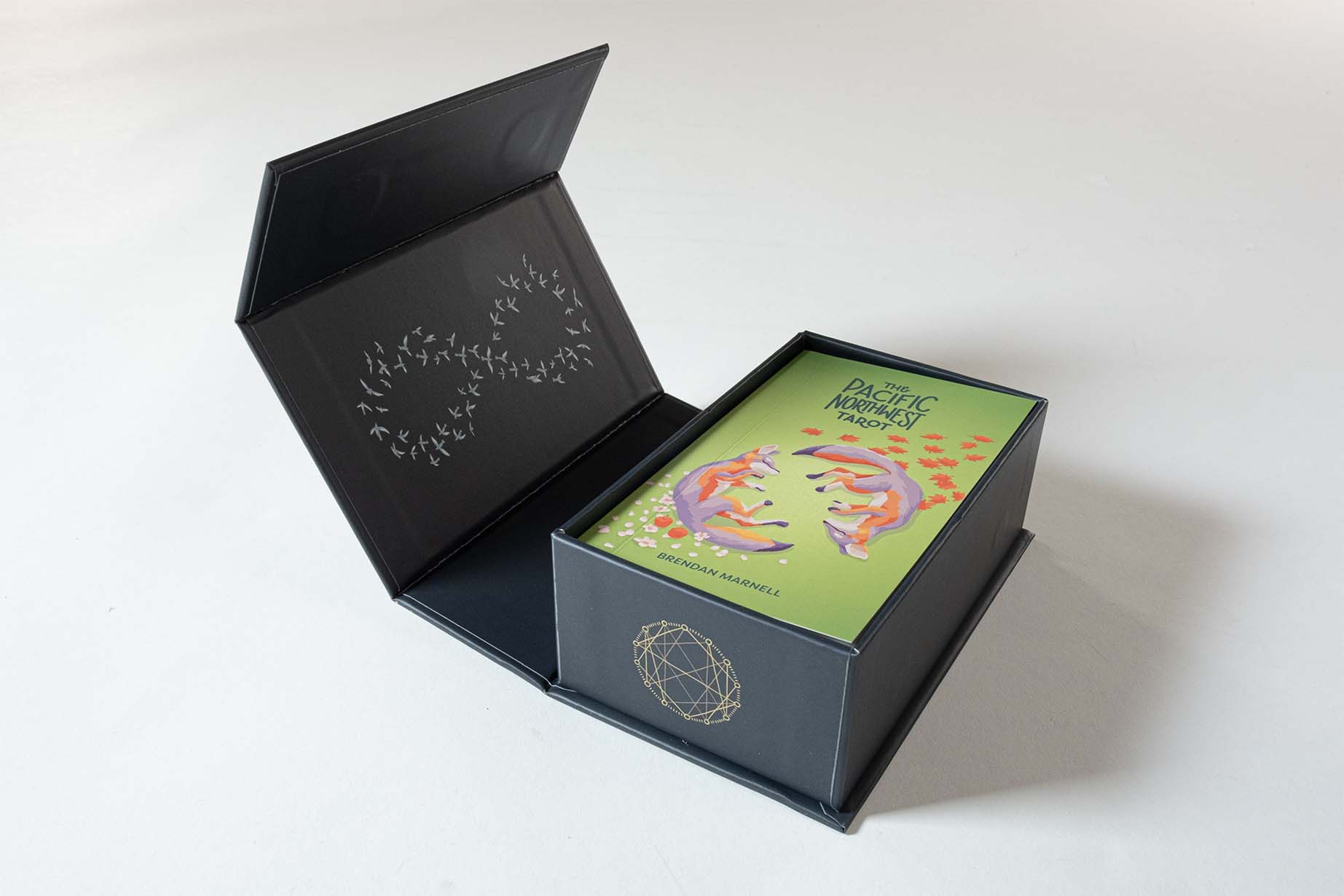

Casebound (Hardcover) Binding

This article will teach you about the hardcover and casebound binding project.

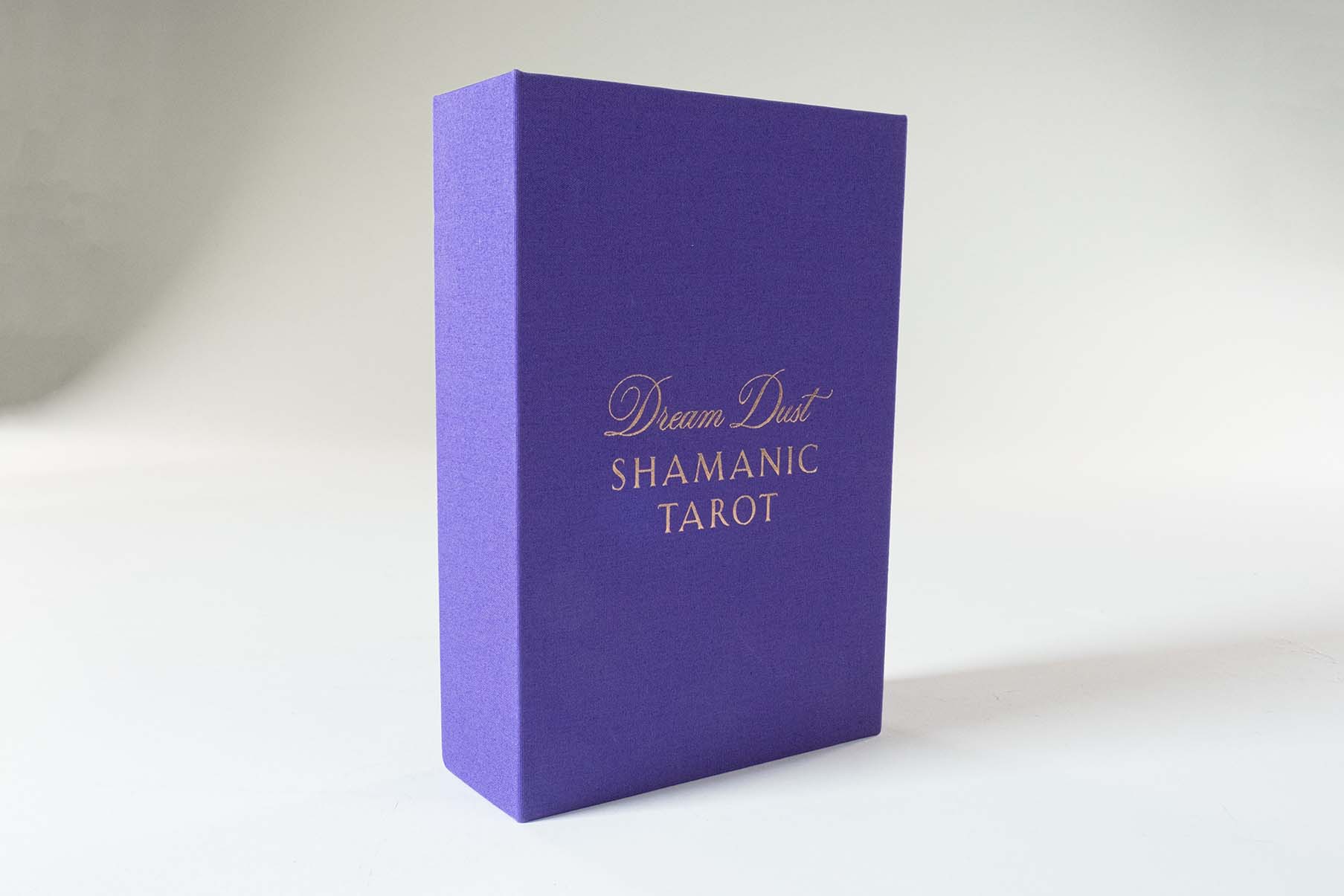

Casebinding, commonly referred to as hardcover binding, involves the construction of an exterior case made of cardboard wrapped with paper. Casebinding is a more complicated process compared to other typical types of binding, but your book is safe in PrintNinja’s expert hands.

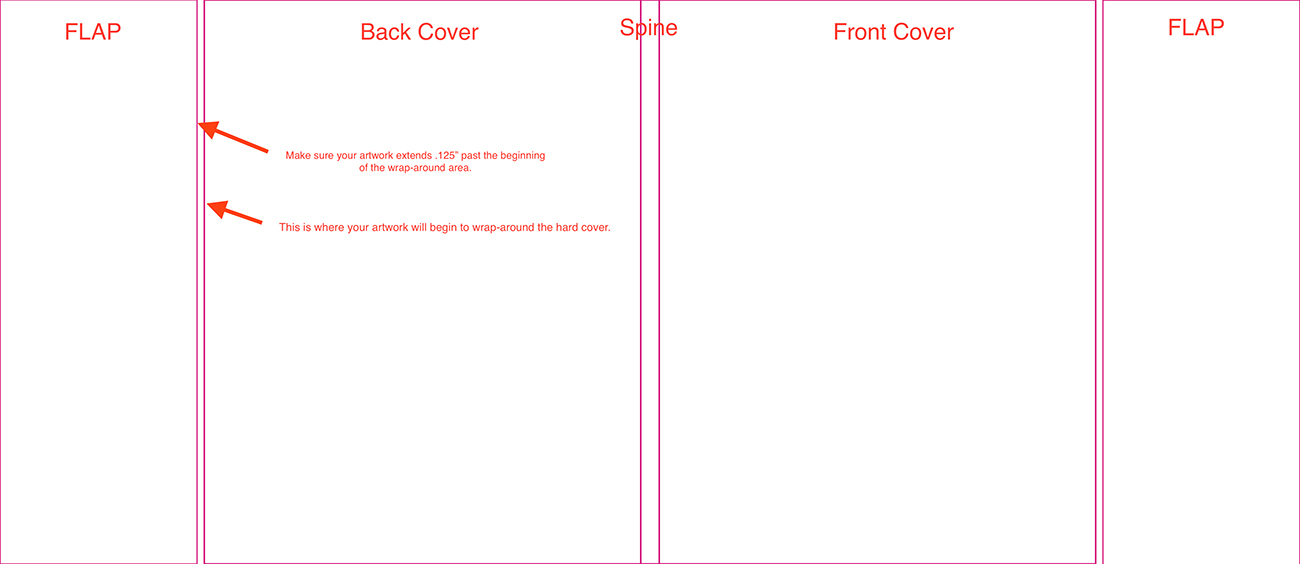

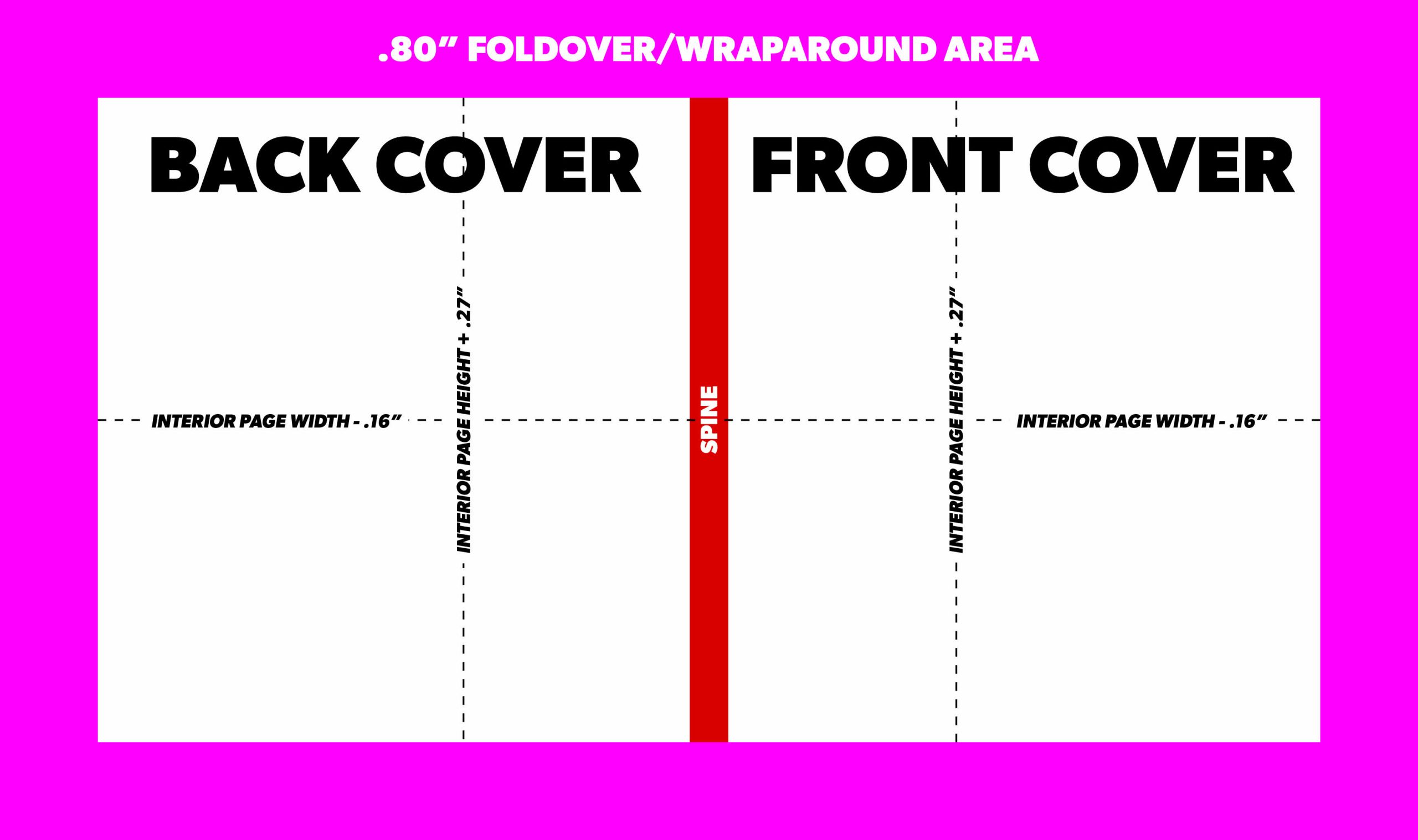

Case Construction

The first step in casebinding is the construction of the hardcover, also known as the case. First, sheets of cardboard are cut to their proper size to form the rigid skeleton of the cover. From there, printed and finished cover sheets are fed into one end of a case manufacturing machine, while the pre-cut cardboard is fed into the other, and the two are combined through several gluing and folding operations into the final case.

Smyth Sewing

Next, the collated signatures of the book block are sewn together using the smyth sewing technique. Smyth sewing uses thread to first sew through the folds of each signature and then sew the entire group of signatures, (also known as the book block) together, resulting in a durable binding that can be opened very wide.

Trimming

Next, the sewn book blocks are trimmed down to size. With some softcover books, this happens after the cover is applied, but because the hardcover case is larger than the book block, in casebinding the trimming step happens before the book block is glued into the case.

Gluing

Finally, the finished book blocks and cases are placed into a hardcover binding machine where they are glued together into a completed casebound book. First, the sewn book block has glue applied to its spine, and a piece of fabric (called the super) is placed on top of the glue. Farther down the line, the hardcover case is wrapped around the book block. At this point, books with 60 pages or more will also have endsheets added to hold the entire book together.

Ready to get started?

PrintNinja’s hardcover book calculator makes it easy to take the next step in creating your hardcover book. Our calculator is pre-populated with popular options, but you can customize just about anything. You can also save your quote for 90 days, so it’s no problem if you’re not quite ready to print yet.

Get Your PriceFreshly updated customer reviews from TrustPilot

Quality Assurance

Most printing facilities will have a Quality Assurance department responsible for inspecting all printed parent sheets during the press run, monitoring the final product for defects, and flagging any issues early on in order to deter waste. Due to PrintNinja’s aggregated leverage, we’re able to make sure that our international vendors maintain a high level of quality for our customers. Many of PrintNinja’s vendors produce books and games for high-profile worldwide publishers.

Book Quality Control

The quality control team follows the standards set by the printing facility, who ultimately decides the quality the product is required to meet. These quality assurance experts will sign off on color, bindery, and press runs by testing your product at random, during different steps of the process.

Game Quality Control

Printed game pieces (game boards, cards, tokens etc.) follow the same quality control measures as books from prepress to pulling printed sheets off the press.

Card game assembly has a few extra steps to ensure consistency. Operators will insert blank pages in-between the full printed card game sheets. When blank cards appear, this signals to operators that the deck they are assembling is ending and a new deck is starting. Each deck once assembled in their packaging is then weighted to make sure a card is not missing or vice versa there’s no extra card.

Game pieces we use have passed safety tests. However, if you need paperwork to present to a retailer or distributor that proves your game is safe to sell then you’ll have to re-run the safety test on your specific game as a whole.

Drying

This article will teach you more about the final step in the process of printing your book: the drying.

The final step in the offset printing process is to dry out your bound books. This step is not necessary for digital offset, which is one of the reasons that digital offset offers a faster turnaround. As you see below, all printed books are compactly stacked on top of each other using that pressure to halt pages from warping. This step is especially crucial for hard cover books; due to the moisture added in gluing and lamination, these covers are prone to curving if there’s no pressure to keep them flat while they dry. Book drying may seem like a boring part of the process as opposed to, say, hot foil stamping, but it’s actually a very crucial part of making your book or other printed project both look great and stay durable.

Many printers will have a designated drying room with controlled temperature and humidity settings to ensure consistency in drying. This insures that if you have multiple runs of books, they’ll be consistent in appearance and durability.

With book drying and the end of your printing process comes exciting news – after your project is done drying, it’s time to think about shipping, storage, and fulfillment of your project!

Freshly updated customer reviews from TrustPilot

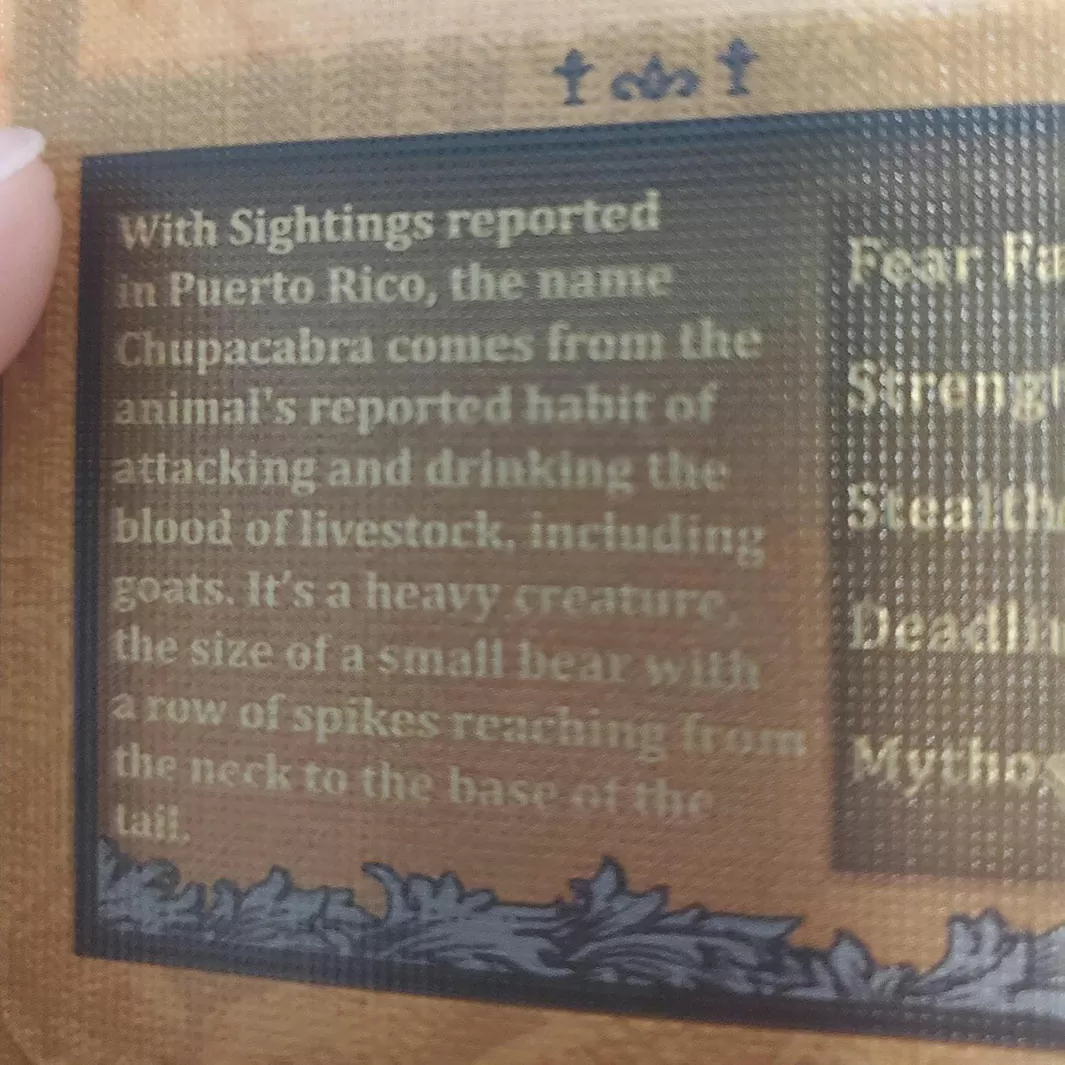

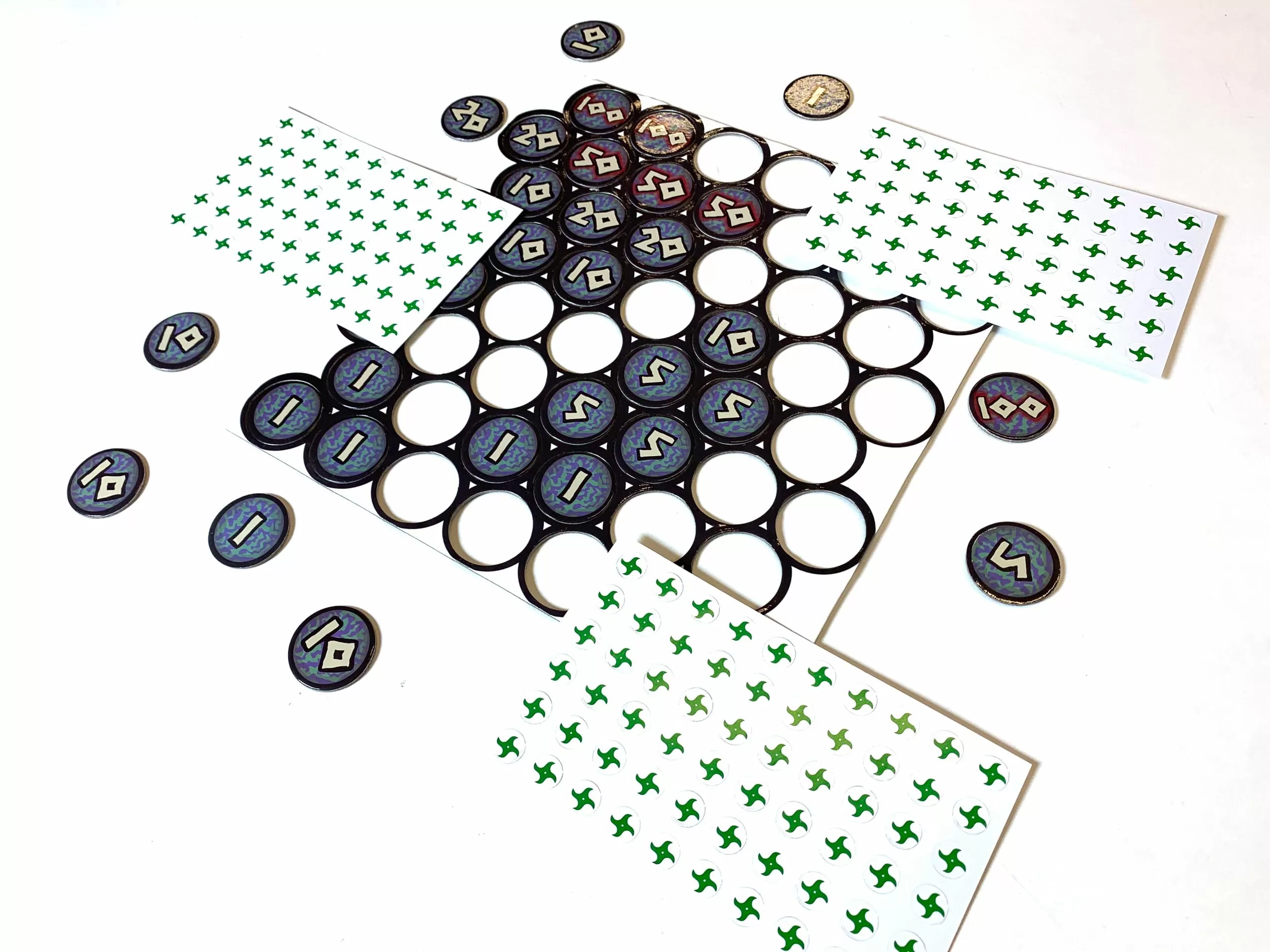

Card Game Production

This article will teach you about the process of card game production.

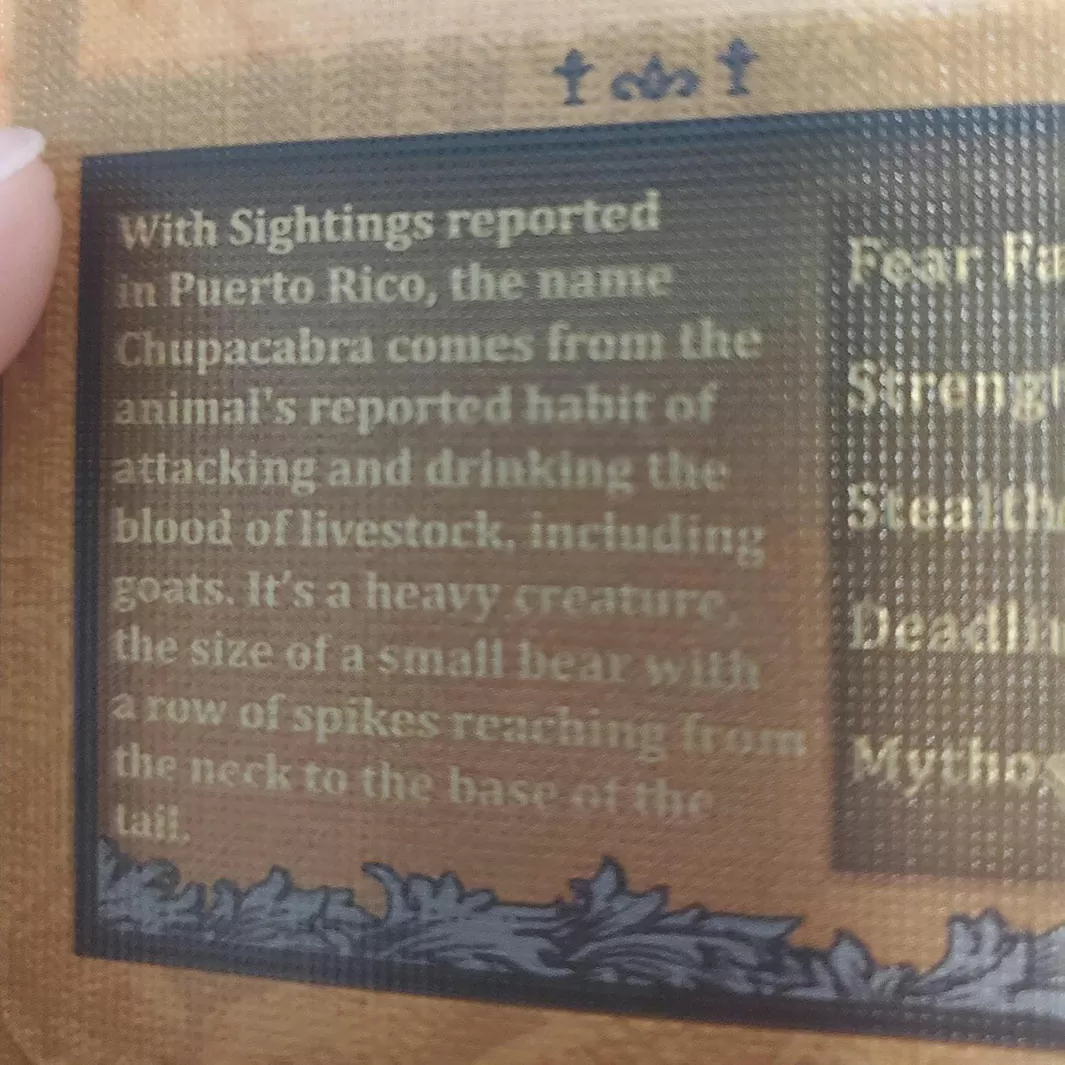

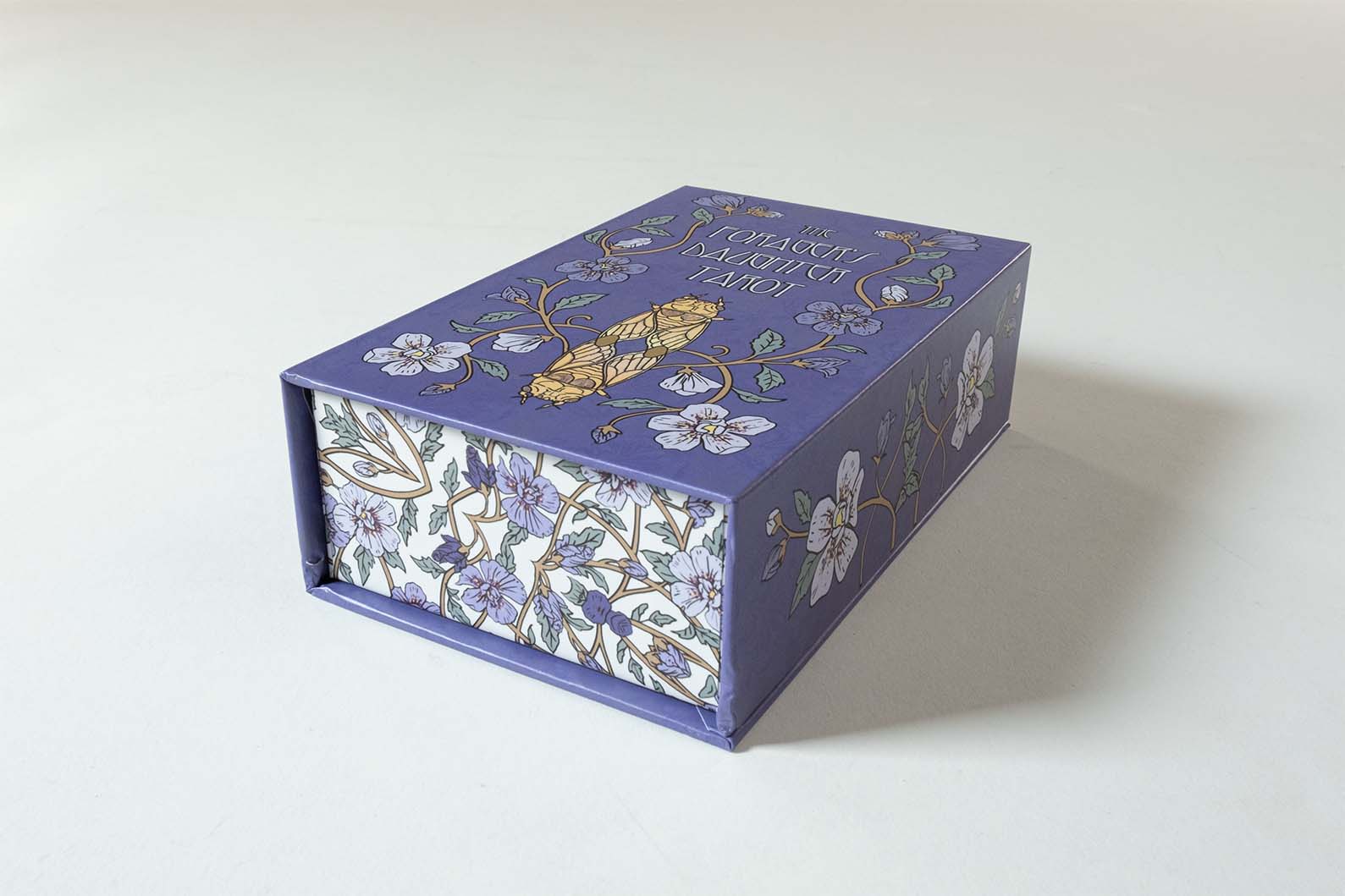

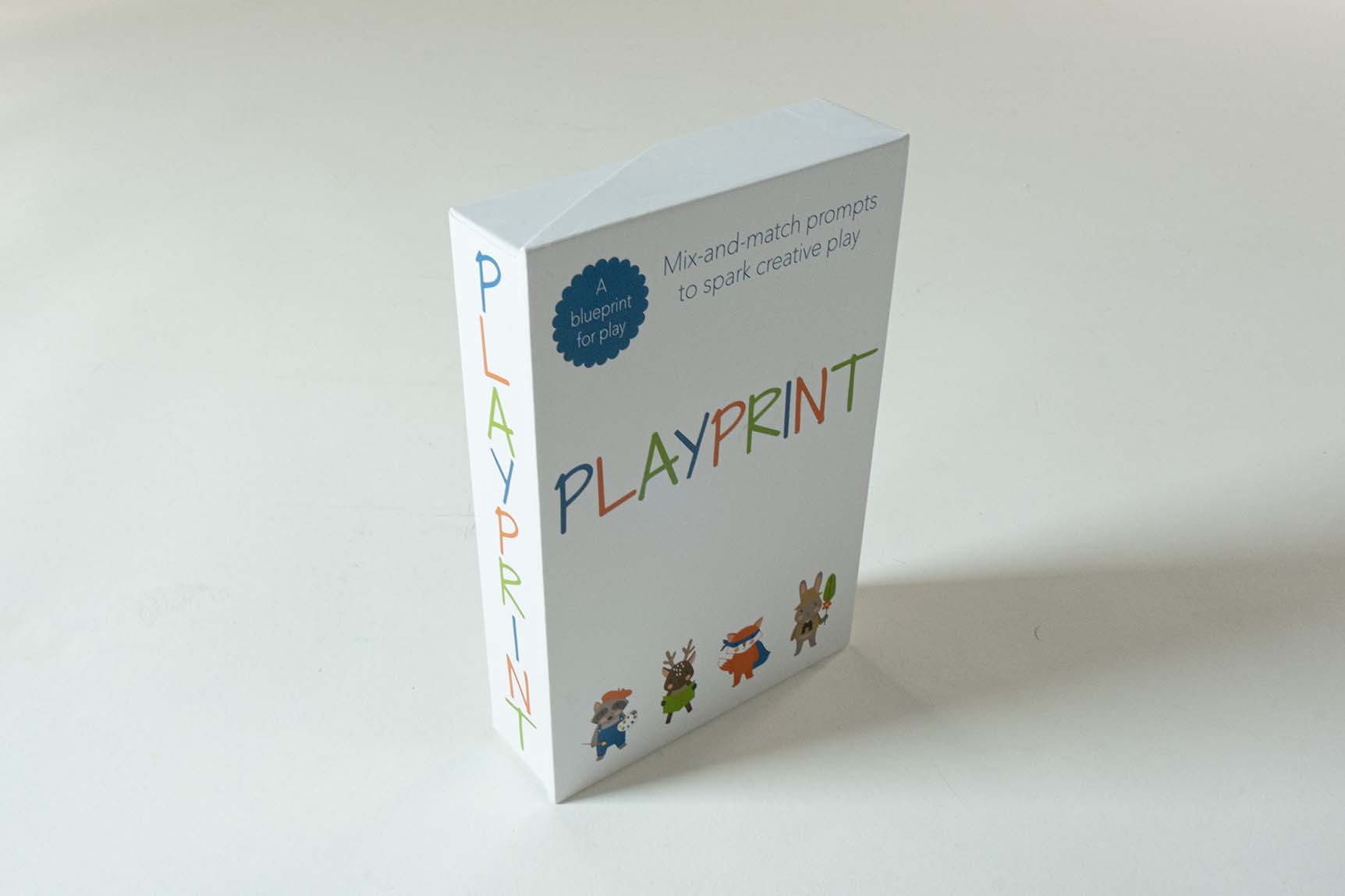

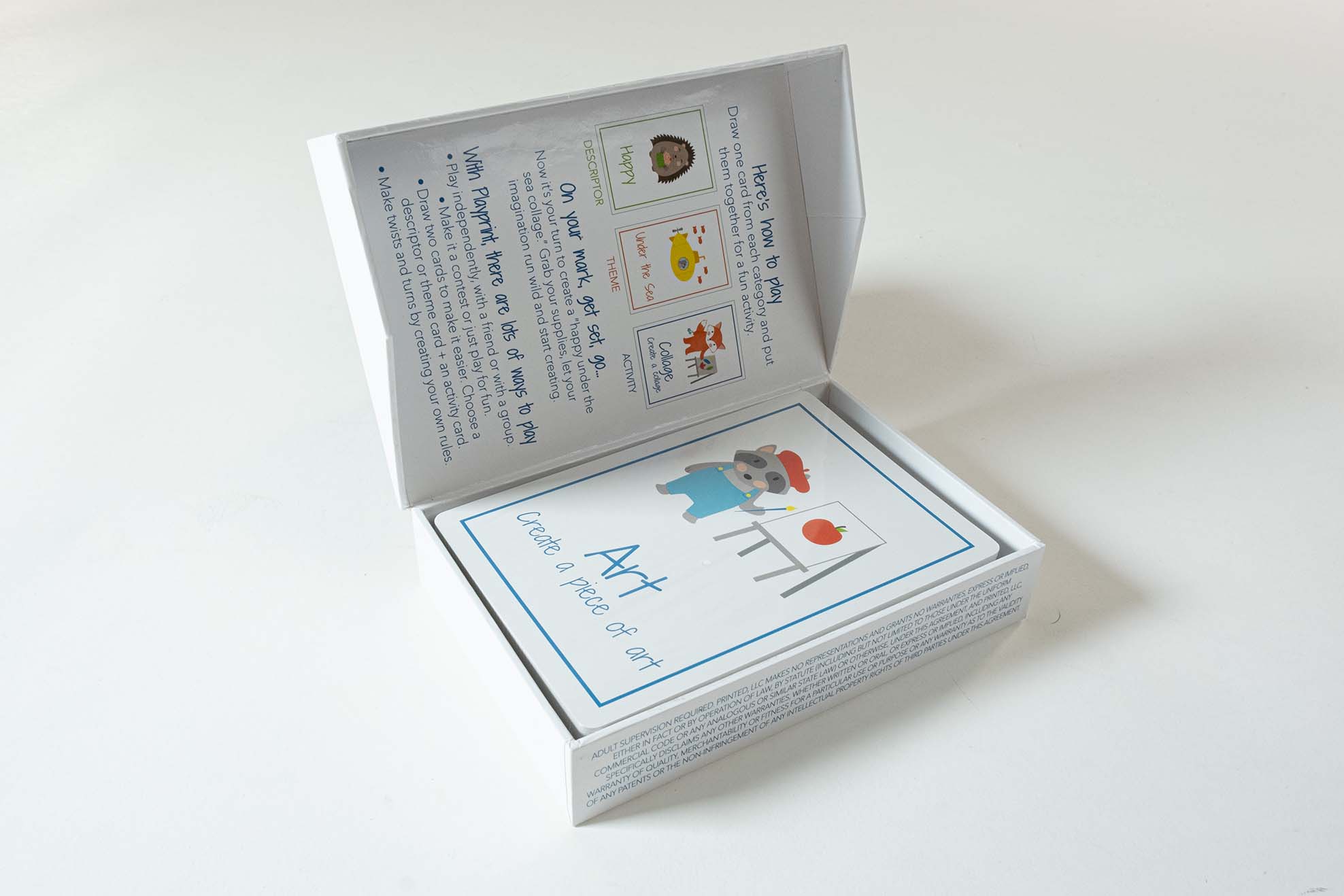

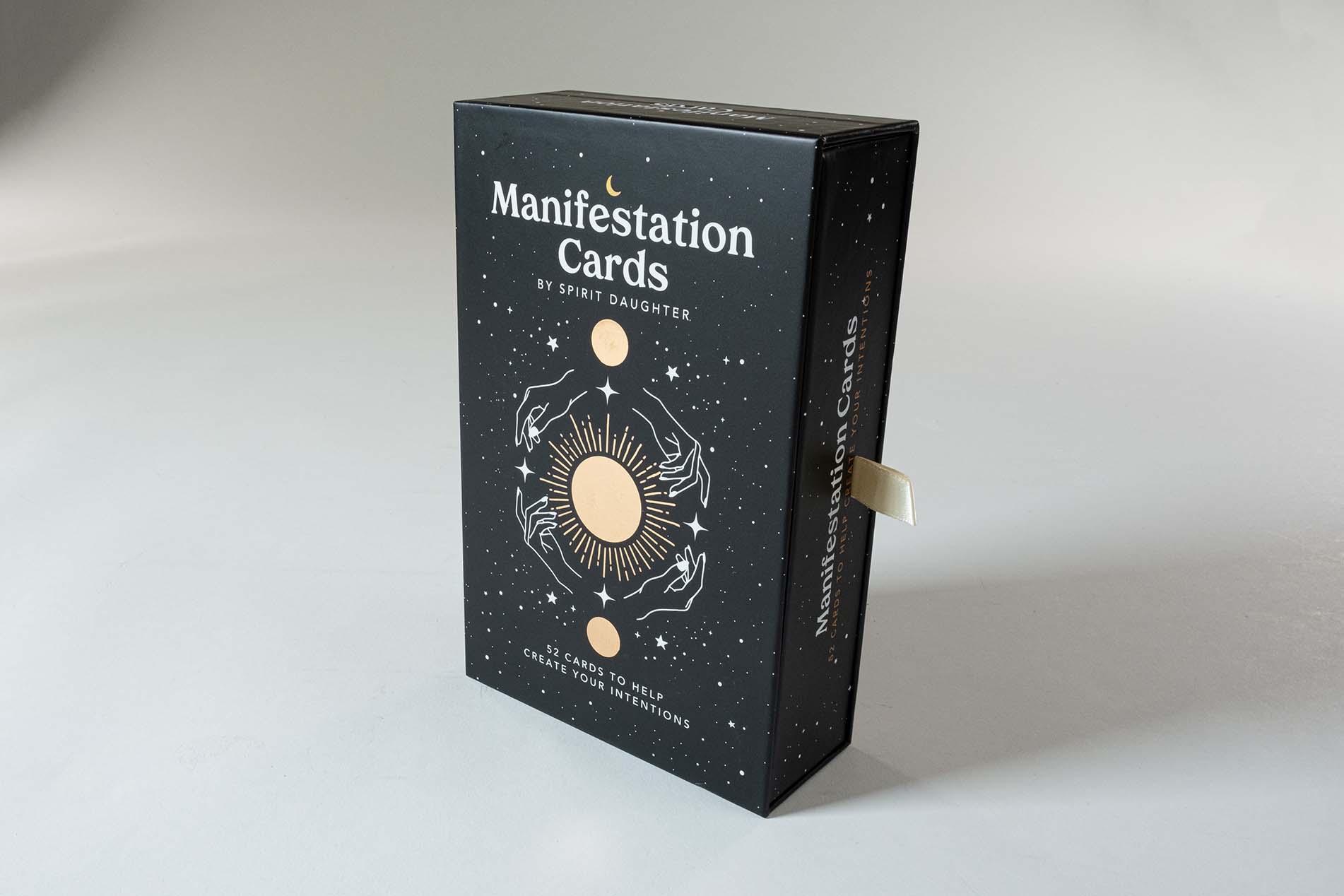

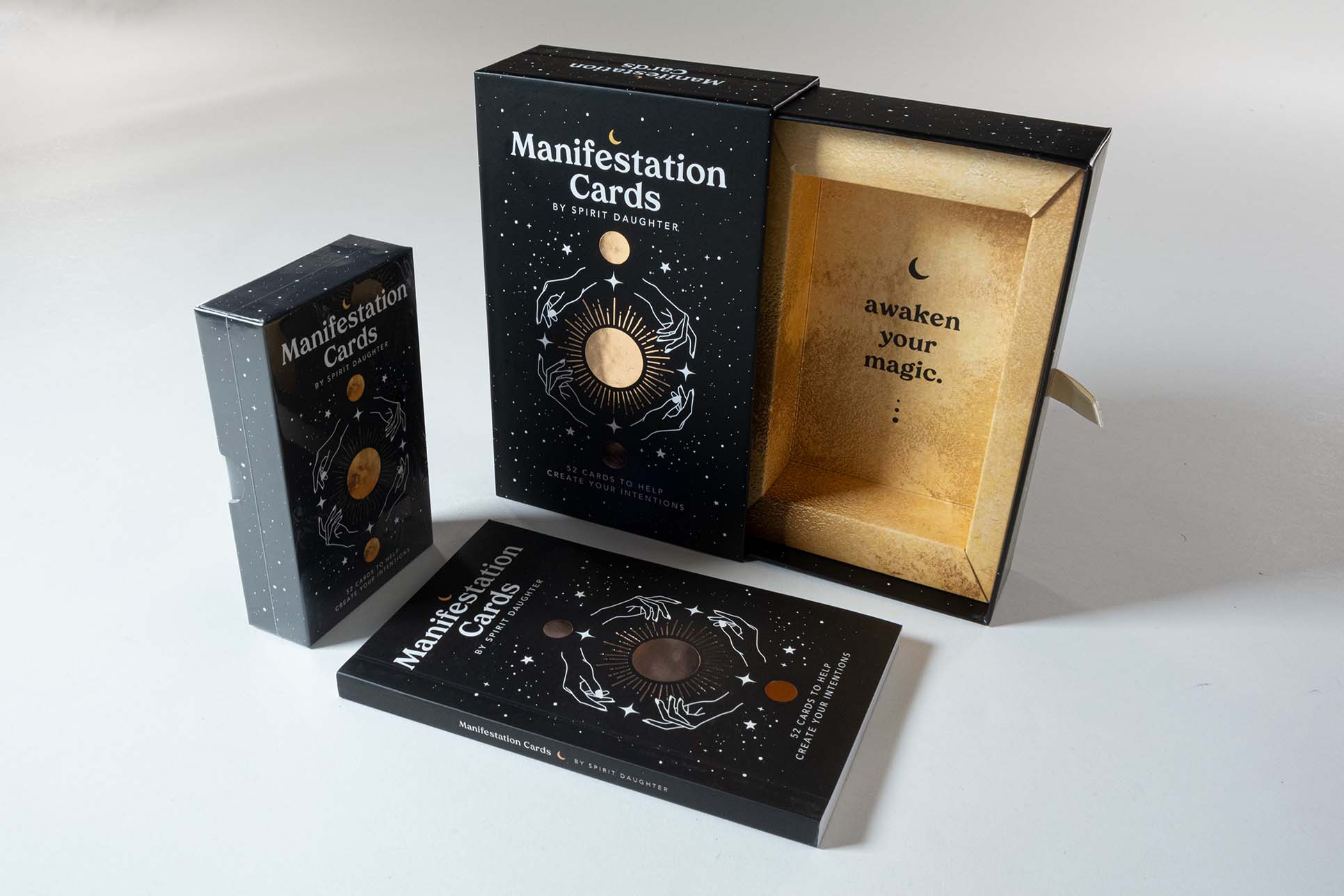

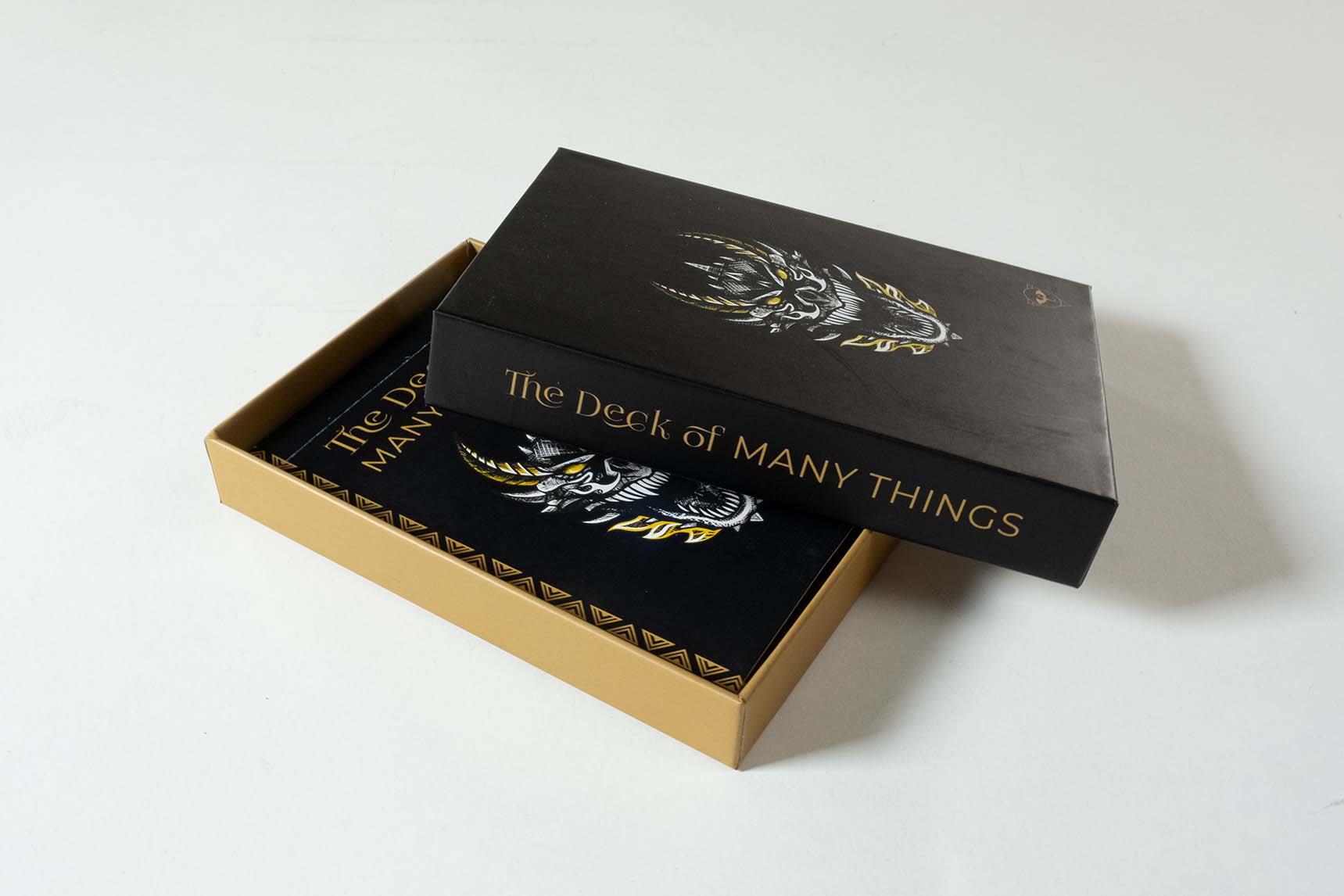

Once both the cards and tuck boxes have been printed onto parent sheets, they are ready to be cut, assembled, and packaged together.

Trimming Cards

The playing card parent sheets are fed one at a time through a calibrated trimming machine. As the sheet makes each turn, blades cut out strips of cards until each card is cut out and stacked in a deck. Our domestic facility uses a rotary die cutter for all of our card projects. The printed sheets will pass through a drum that holds a die with the size and shape of your cards, held on by powerful magnets. The die trims for size and rounded corners at the same time.

Die Cutting Boxes

A tuck box’s unique shape requires the die-cut method to extract the box and its unique flaps from the parent sheet. Die-cutting requires an operator to form blades to the box’s shape and use heavy pressure to cut out the design, as seen in the video below.

Smoothing and Rounding Cards

The trimming machine leaves rough edges around the perimeter of the cards and square corners. To shape them, an operator pushes stacks of cards through a “smooth edge machine” installed with the appropriate die size. The pressure of the cards being pushed through the dies leaves the edges smooth and rounds the corners at the same time. Most playing cards have rounded corners to prevent the corners from being damaged; however, some creators do request square corners.

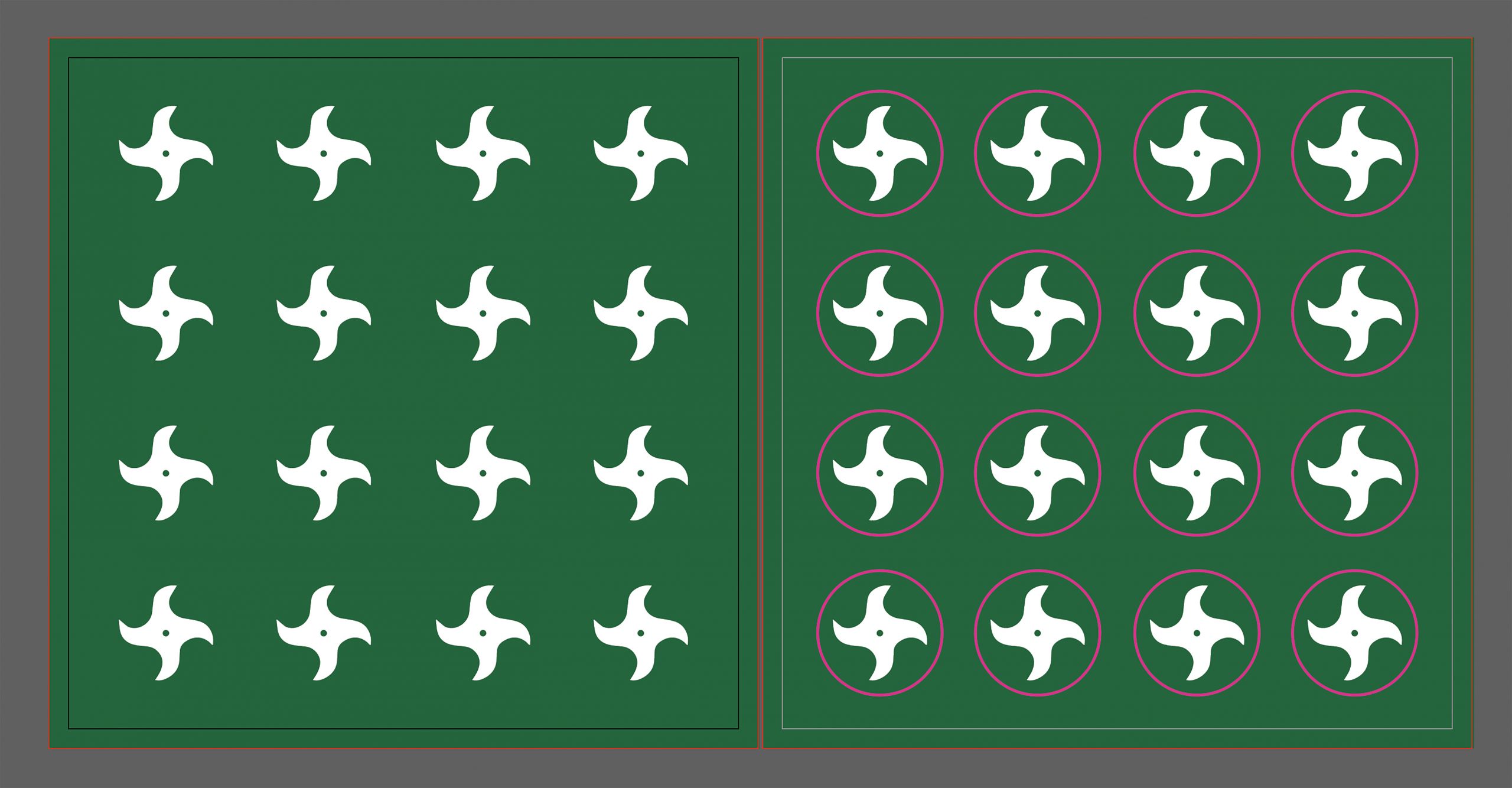

Adding Linen Texture Finish

Linen texture is a specialty finish that adds a tactile crosshair texture. Bicycle branded playing cards are known to have this linen finish. The texture is applied after your cards are printed on a parent sheet and before they are cut to size.

The printed sheet is forced under a heavy metal roller with the crosshair pattern. The weight of the cylinder applies it’s marks to the printed paper. These sheets are then trimmed to size and put through the rounded corner machine.

Assembling Cards into Tuck Boxes

When all the pieces are printed and cut, all that’s left is to assemble them together. Cards are organized on parent sheets in the order that they are to be assembled into each box, so collation is taking place at the same time they are being trimmed.

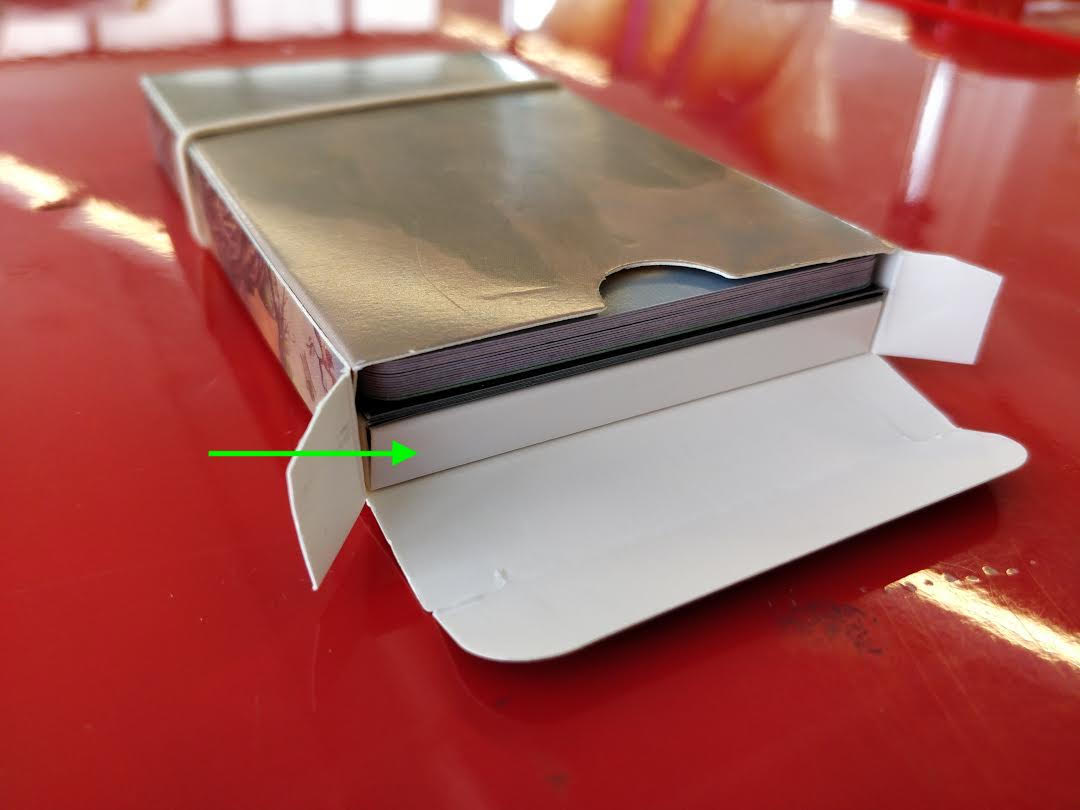

The cards arrive at the assembly line in crates with each deck completed and separated. Tuck boxes are folded to form and have a glue dot applied to the bottom flap for extra durability. Cards are then placed inside and sealed.

Shrink-wrapping Final Product

Most card games will be shrink wrapped for added protection from theft and dirt. This is a necessary step if you plan to sell your game to retailers, who require your games to be delivered in shrink wrap and sometimes even with hang tags applied.

A shrink wrap machine works in three steps:

- The operator wraps the box in plastic shrink film.

- The film is sealed by a heavy clamp on the machine, with a straight seam line.

- The machine applies heat to the film that release the cold air out of tiny holes, causing the film to shrink to the shape of the box.

Freshly updated customer reviews from TrustPilot

Logistics

This article explains some of the complex process of international shipping logistics.

International trade can be an incredibly complex endeavor. Not only do you have to arrange to get goods from one country to another via some combination of ocean, air, truck, and rail, you’ve got to be familiar with all of the trade regulations and laws that affect commerce between the two (or more) countries in question. You’ve also got to be able to communicate with your counterparties in the other country, doing business across language barriers which may range from mildly confusing to impenetrable. Finally, participants in international trade don’t benefit from many of the legal protections that domestic consumers take for granted, leaving the buyer exposed to potentially catastrophic loss if something goes wrong, even if it’s not their fault. But, when you print with PrintNinja, you can rest assured that we’re taking care of all the logistics for you, from the factory to your front door. We communicate daily with our team in China, so you can feel confident that your printing project is being treated with the utmost respect.

International Shipping Logistics Chapters:

Freshly updated customer reviews from TrustPilot

Air Shipping

Air shipping is the fastest mode of transportation available, but that speed comes with a hefty price tag.

Shipments that are sent from China to the US via air typically take approximately one week to arrive, much less time than ocean shipping, which takes approximately six weeks to get finished goods from the factory to your door. For an additional charge, air shipping time can often be cut down even further and a guaranteed delivery date can be hit, which is never the case with ocean shipments.

Air shipping is the most direct shipping pathway. Once the goods are finished, export documentation and paperwork are submitted, and the goods are delivered to the carrier’s warehouse. From there, they’re loaded onto a plane and flown to the airport closest to their final destination, where they go through import customs. After clearance, they’re taken to the carrier’s local warehouse and dispatched via one of the carrier’s trucks for delivery.

Small air shipments (under 50kg) go through a much faster and simpler customs process, removing one potential obstacle in the logistics timeline. Larger shipments (over 50kg) have to go through a more extensive customs process, similar to ocean shipping.

PrintNinja offers partial expediting services, meaning you can send some small portion of your goods using expensive, fast air shipping, while the bulk of your order travels via more cost-effective, slower ocean shipping.

We also have a Premium Expedited option that can bring the 1-week expedited turnaround down to about 3 days. These shipments must be custom quoted and your timeline must be confirmed with your account manager before your order is placed.

Ocean Shipping

Ocean shipping is the most cost-effective way to get goods around the world, as goods are packed into standardized shipping containers and loaded onto mega-sized container ships. It can take a long time, and the delivery dates can’t be guaranteed, but the process is so efficient that thousands of pounds of goods can be moved tens of thousands of miles for relatively low cost. Let’s walk through the various steps involved in getting a typical ocean shipment from a foreign factory to your door:

Export Customs

Once your goods are finished, the exporter files paperwork and pays documentation fees to get them ready for export. Once this documentation is filed, the goods are trucked from the factory to a shipping warehouse for consolidation into a shipping container.

Shipping Containers

At the shipping warehouse, your goods are loaded into a shipping container. Shipping containers are gigantic steel boxes that are most commonly 8 feet tall, 8 feed wide, and either 40 or 20 feet long. Because these containers are so standardized, they can be loaded and unloaded very efficiently onto oceangoing container ships. Once the container is full, it is sealed and delivered to a bonded customs warehouse for export.

Ocean Liner

Next, the shipping container with your goods in it is loaded onto an ocean liner known as a container ship with thousands of other similar containers, and the ship makes the ocean journey from the country of export to the country of import, where the containers will be unloaded. Modern container ships are so gigantic that they can only dock at a handful of deepwater ports across the world that are equipped to handle their size, making the ports a very scarce resource. This has made labor relations very difficult at these ports, and slowdowns and strikes have happened every few years when union contracts have come up for renegotiation.

Import Customs

Once the container has been unloaded from the ocean liner, it goes through customs in the destination country. This is the most unpredictable stage of ocean transport, as containers are occasionally flagged for a random inspection, adding anywhere from a few days to a few weeks of delay depending on the type of inspection. Once customs have been cleared, the container is delivered to the ground shipping warehouse.

Ground Shipping

At the ground shipping warehouse, the contents of the shipping container are separated, labeled, and shipped out via truck to their final destinations. This is the first step of the process where reliable tracking information is available, as most ocean carriers do not provide the type of high-quality tracking information that many people are used to receiving from UPS, FedEx, or their domestic mail service.

Freshly updated customer reviews from TrustPilot

Customs, Duties, and Taxes

Read on to learn more about how PrintNinja works with customs policies.

The complexity of handling customs, duties, and taxes on any given international shipment depends on the laws and trade agreements in place between the exporting and importing countries. Countries with free trade agreements can make such transactions much simpler, while duties and tarriffs are often in place to intentionally make it harder for certain types of goods to be imported/exported economically.

Customs

Every country has an agency that handles customs and imports. In the United States it’s US Customs and Border Protection, and in China it’s the General Administration of Customs. These agencies are responsible for regulating all shipments into and out of their parent country, enforcing their countries’ trade laws and customs policies, and collecting all applicable duties and taxes.

Duties and Taxes

Duty fees are based on the contents of your shipment and any applicable duties in place on that type of product. Depending on the two countries in question, some goods may be imported duty-free, while others may be subject to steep fees. In some countries a VAT(Value-added Tax) or GST(Goods and Service Tax) is also assessed at various rates, depending on the product being imported.

Freshly updated customer reviews from TrustPilot

Storage and Fulfillment

This article will help you learn more about your storage and fulfillment options for your project once it’s been printed with us.

You’ve made it through order placement, production, and international logistics, and your project has finally arrived at your door! So, what to do with the pallets of books that just landed in your driveway?

Do It Yourself

Some folks like to handle everything themselves: warehousing, fulfillment, inventory, tracking, and shipping for day-to-day orders. Not to mention providing customer service via email or phone. This is a great route to take if you can manage it, but be sure not to underestimate just how much work DIY storage and fulfillment is, how much space it requires, and how much additional cost it adds!

If you’re planning to handle storage yourself, check out our visual guide for tips and tricks on how to properly store your project:

Third-Party Warehousing / Fulfillment

Another option is to use a third-party warehousing and fulfillment service. One of the most popular choices is Amazon’s FBA (Fulfilled By Amazon) program. Amazon is a great option for managing your project and handling day-to-day orders, but Amazon requires quite a few steps toward receiving goods and establishing a functioning account. We highly recommend downloading the below “Amazon Fulfillment Process” PDF to get a step-by-step guide on printing with PrintNinja and fulfilling with Amazon.

Download Amazon Fulfillment Process Guide Here

There are also many independent warehousing and fulfillment companies. Printninja has a partnership with E Fulfillment Services, which is a company that will store your books and ship them out on an as-needed basis. Plus, if you mention Printninja when getting a storage quote with EFS, you’ll be eligible for discounted pick & pack rates!

Remember that many third party warehousing and fulfillment companies have huge economies of scale. Their warehouses are so advanced and their freight rates so low that in many cases you can actually save money by going with a third party service.

Freshly updated customer reviews from TrustPilot

Advanced Concepts

The links in this section will help you learn advanced concepts about offset printing.

PrePress

Learn about the difference between CMYK and RGB, color variance, and pantone/spot color.

Press

Learn about what manufacturing variance is and how it impacts your order.

Post-Press

Learn about board book binding, spiral/wire binding, and safety testing your project.

Specialty Features

Learn about all the specialty features we offer, like foil stamping and spot UV, embossing and debossing, and the cloth/PU leather process. Also learn about endsheets, the die cutting process, and newsprint.

- Endsheets

- Foil Stamping Process

- Spot UV Process

- Emboss/Deboss Process

- Die Cutting Process

- Cloth/PU Leather Process

- Newsprint

Distribution

Learn everything you need to know about getting your project out in the world, like ISBN/barcode requirements, copyright information, library placement, and pricing fluctuations.

After you’ve learned about all of these advanced concepts, you’ll be totally ready to understand the process of offset printing your project with PrintNinja. Have any other questions that aren’t addressed here? Feel free to contact us and our customer service team will be happy to help you.

Freshly updated customer reviews from TrustPilot

Overprinting

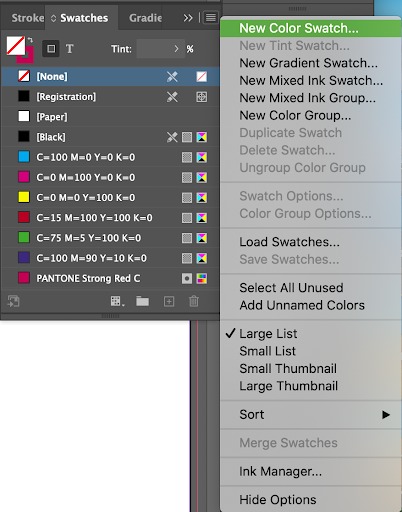

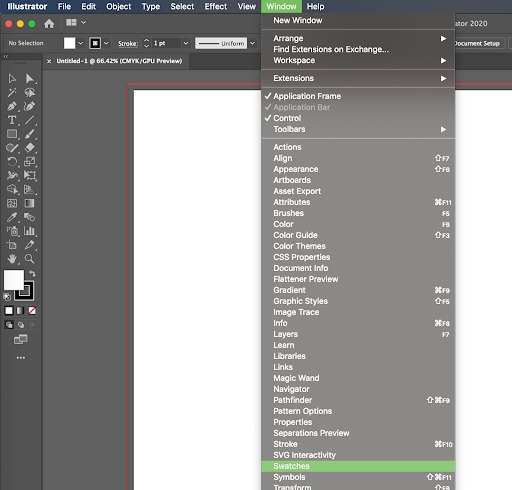

Overprinting

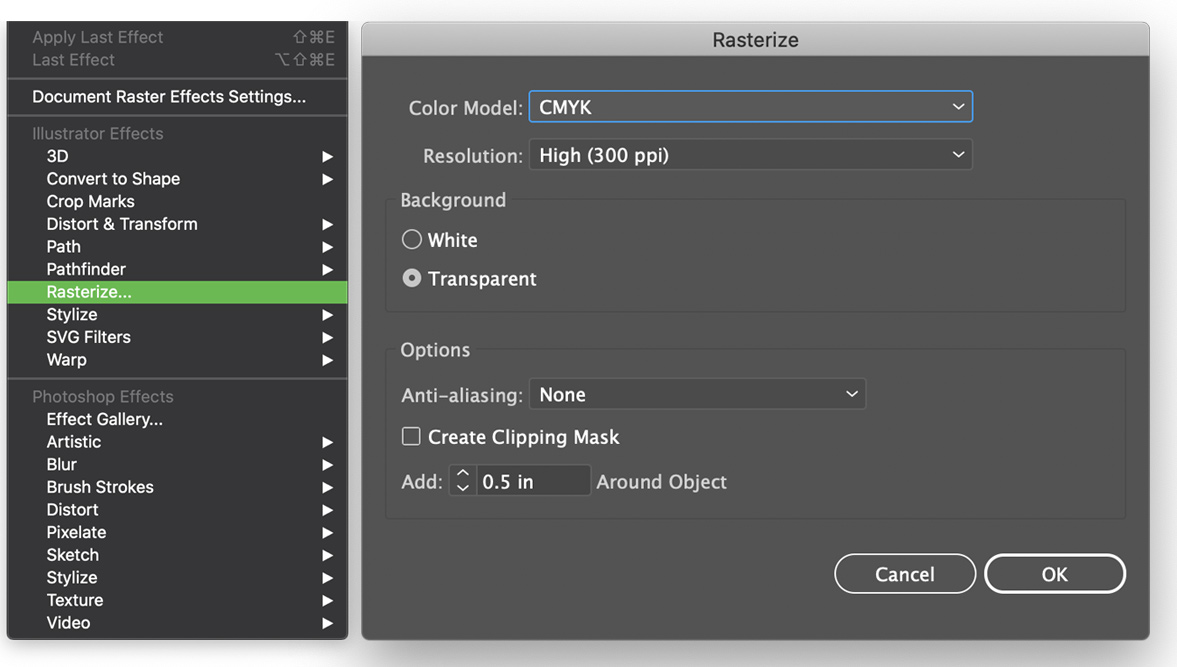

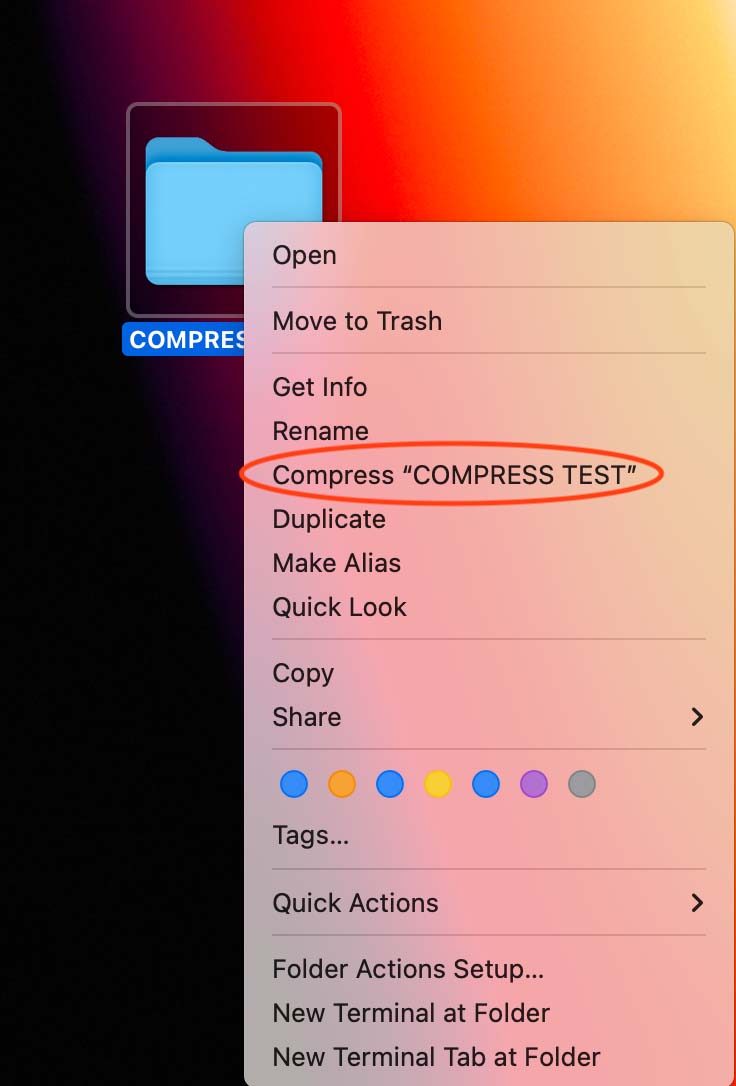

Overprinting is an advanced printing technique that should only used by creators who understand how to implement it properly. Overprinting is the process of printing one color on top of another color. When this happens unintentionally, the bottom color can show through the top color and ruin the quality of your printed materials. In Adobe-based programs such as Illustrator and InDesign, objects colored black can have a default setting for overprinting assigned to them. Luckily, you can easily adjust that on your end by following our simple step-by-step video instructions below.

Alternatively, when objects are not set to overprint, the result is a knockout of the color underneath. The color from the bottom artwork layer is unprinted (or “knocked out”), leaving only the color from the top artwork layer. This is the default state of all non-overprinting objects ensuring colors won’t get mixed, muddied, and oversaturated.

Please watch the following video for more details and step-by-step instructions covering how to check for overprinting and turn off overprinting in your artwork:

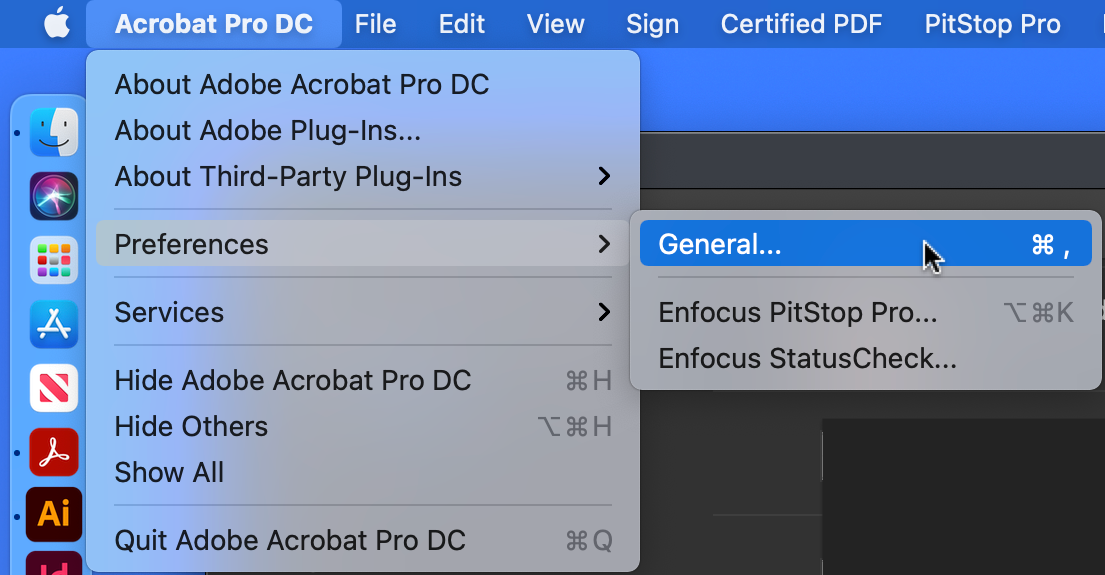

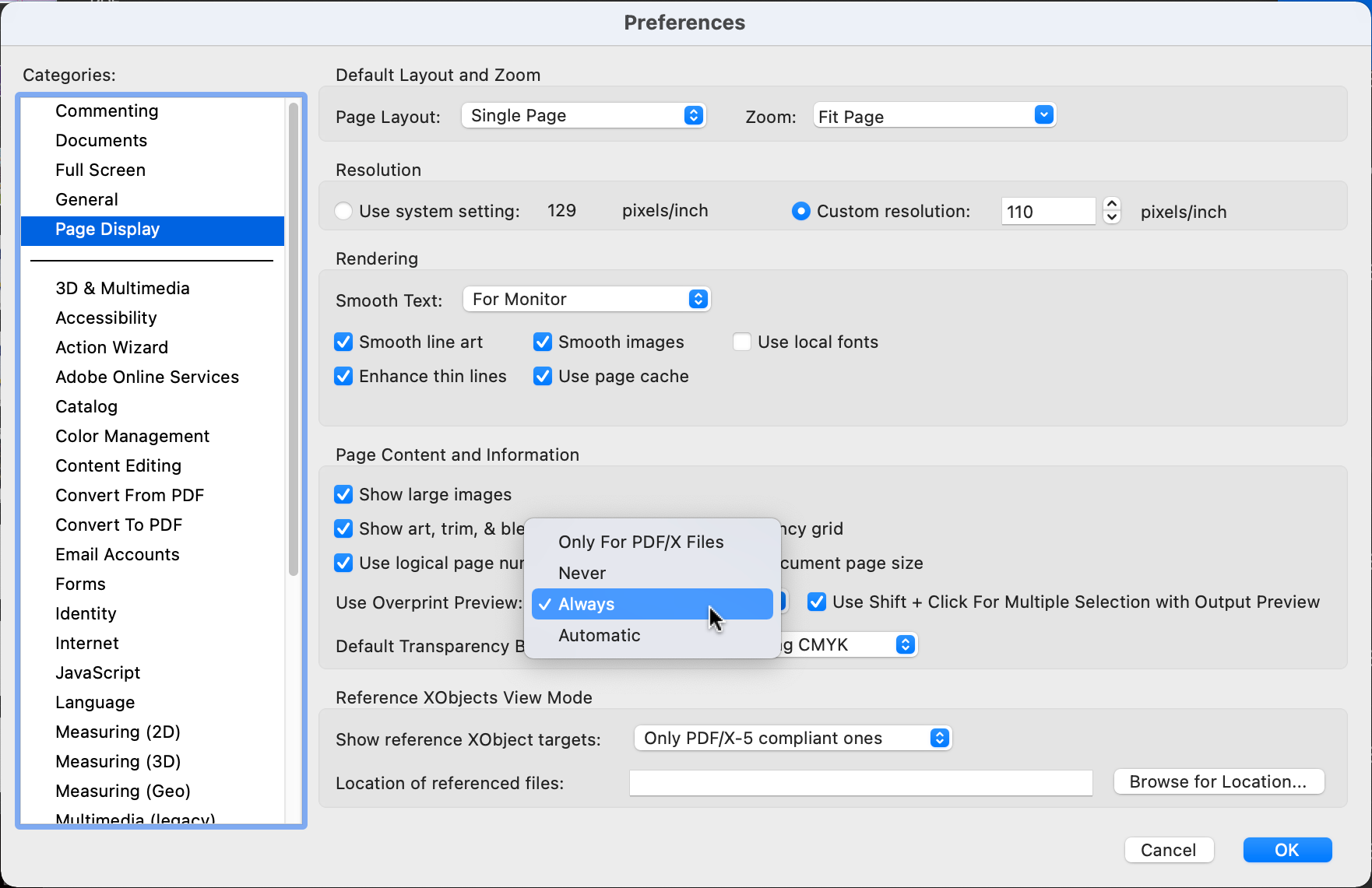

PLEASE NOTE: Overprinting may not display properly in our electronic proof PDFs unless you have followed the directions highlighted here to adjust your overprint preview settings in Acrobat. Even still, overprinting may not be abundantly obvious on a digital monitor.

Hard copy sheet proofing for printed projects and hard copy proofing for game projects are excellent ways to see in-person if a particular object is set to overprint. Hard copy proofing is always recommended and the peace of mind is a true investment into your overall vision.

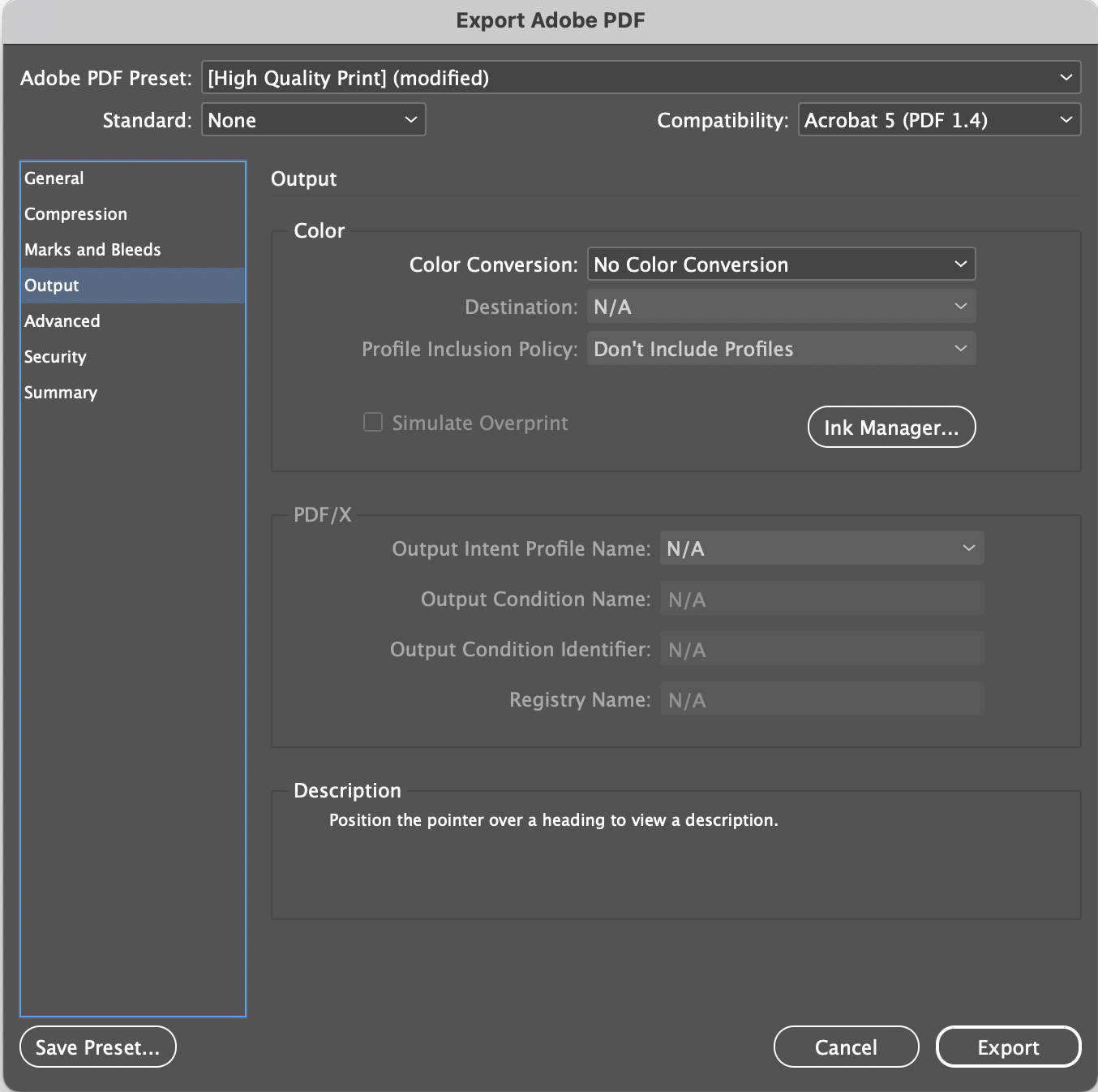

CMYK Printing vs RGB Advanced Explanation

So, what is CMYK printing?

Without a doubt the single biggest issue we run into here at PrintNinja arises from confusion about CMYK and RGB.

We address this briefly in our PrintNinja Printing Color Guide, but you’ve reached the advanced version so now it’s time to dig a little bit deeper into the physics behind these two methods of creating color, and explain why it can be so frustrating to try and convert between the two.

PrintNinja Tip

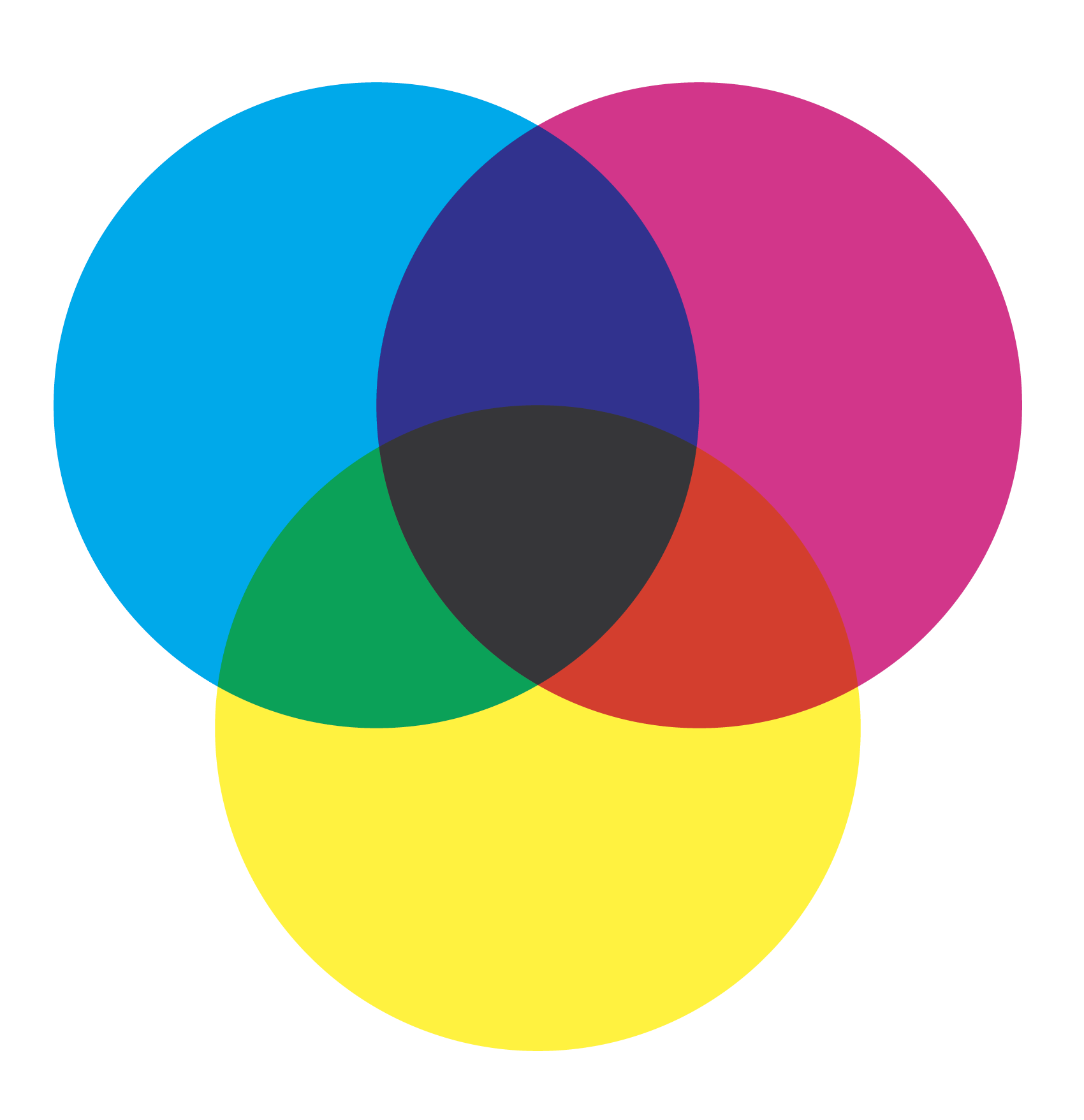

RGB creates colors by blending the three primary colors of light: Red, Green, and Blue. It is used by devices that generate light, such as computer monitors, TVs, or LCD screens.

RGB Color Profiles

RGB is known as an ‘additive’ color profile, because you add the primary colors of light together to create new colors:

Green and Blue light combine to make Cyan

Blue and Red light combine to make Magenta

Red and Green light combine to make Yellow

Red, Green, and Blue light combine to make White

RGB has a very wide color gamut, meaning it can produce many colors, because RGB is actually how our eyes perceive color. We have 3 different kinds of ‘cone’ cells located in our retinas, one each for perceiving Red, Green, and Blue light, and our brain combines the signals these cells receive and interprets them as color.

The key thing to remember about RGB color is that RGB can only be used by devices that generate light.

Printed items obviously don’t generate light, they can only reflect the light that hits them. Thus, they need to use a different color scheme, one based on reflecting light instead of producing it. This is where CMYK comes into play.

PrintNinja Tip

CMYK creates colors by blending four colors of ink: Cyan, Magenta, Yellow, and blacK (also known as Key). It is used to print in full color on items that reflect light but do not generate it, such as paper and fabric.

CMYK Color Profiles

CMYK is known as a ‘subtractive’ color profile, because each ink removes a primary color of light from any white light that hits it:

Cyan ink reflects Green and Blue light, but not Red

Magenta ink reflects Blue and Red light, but not Green

Yellow ink reflects Red and Green light, but not Blue

This gives us a backwards way to reflect the three primary colors of light via subtraction:

Cyan and Magenta ink combine to only reflect Blue light

Magenta and Yellow ink combine to only reflect Red light

Yellow and Cyan ink combine to only reflect Green light

Starting with a white piece of paper, which reflects every color of light, we can use Cyan, Magenta, and Yellow inks to subtract specific colors of light to make a wide gamut of colors.

Theoretically, combining Cyan, Magenta, and Yellow ink makes black, but because inks are not perfectly aligned to our RGB vision, we also add blacK ink (Key), which reflects no light, to help provide darker tones and truer blacks.

Issue with Converting RGB to CMYK

Because the CMYK profile is forced to subtract light instead of generate it, it cannot produce anywhere near as wide a spectrum of colors as RGB. Especially vivid primary light colors such as pure Red, Green, and Blue will often appear muted or dulled upon conversion to CMYK.

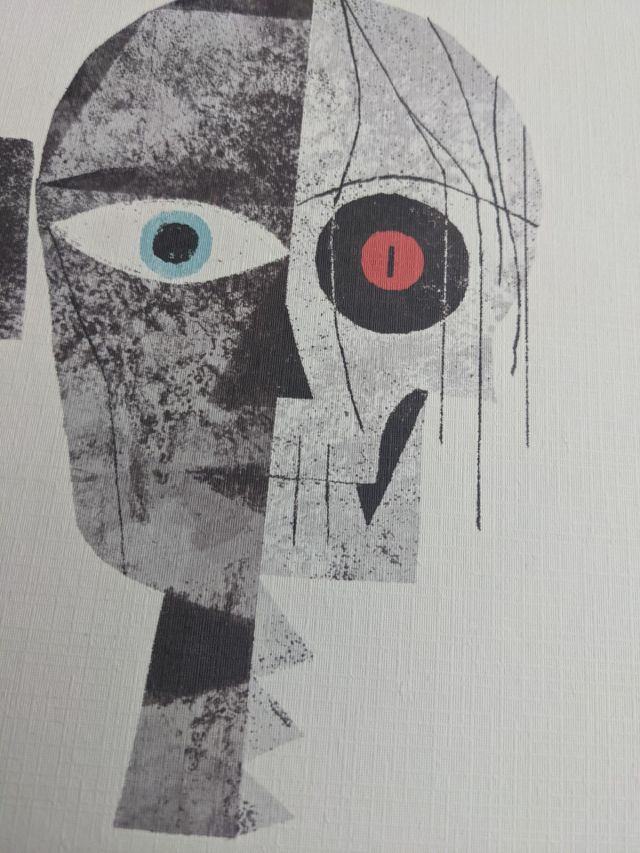

The illustration to the left compares the gamut of colors achievable with several different RGB profiles vs. the much smaller gamut achievable with CMYK.

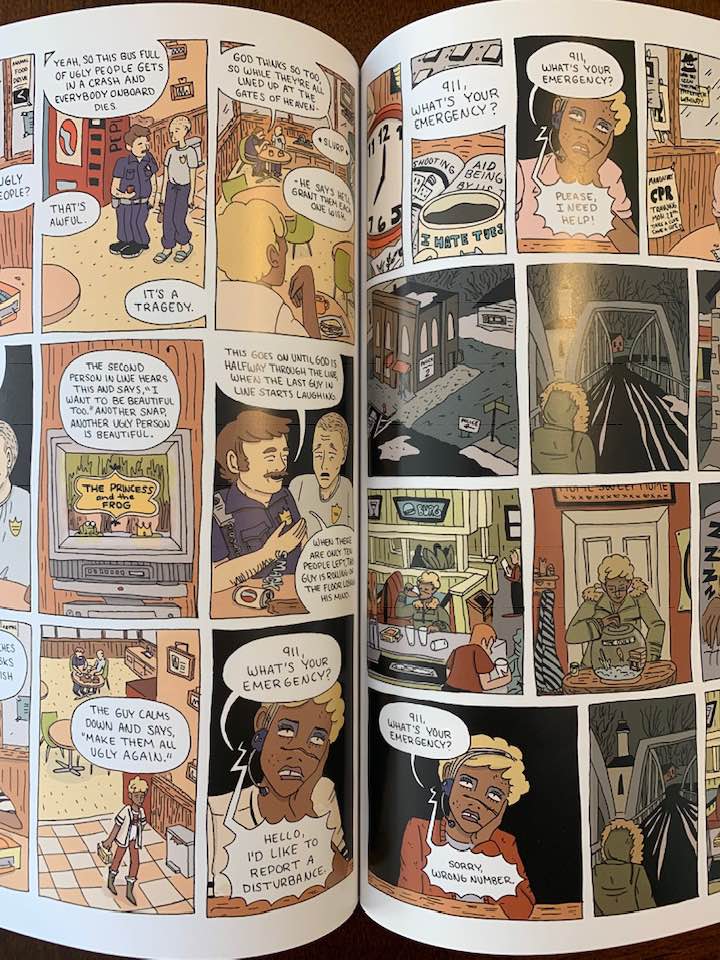

This is why many creators who work primarily on computers and tablets, and whose work is most often viewed on computers and tablets, (such as webcomics creators) are often disappointed when they see how their colors look after being converted from RGB to CMYK.

This is also why CMYK can be converted to RGB and reproduced fairly accurately on a computer screen (which is what is physically happening when you set your color mode to CMYK in your graphics program), but RGB cannot be converted to CMYK and reproduced accurately on the printed page (which is what happens when you open an RGB image and hit “print” on your computer).

How to Stay in the CMYK Gamut

If you are using Photoshop or InDesign look out for the ‘out-of-gamut’ warning icon (triangle with exclamation point) that pops up in your color picker tool. This tells you that the selected color will not print accurately using CMYK production, offset printing.

Sometimes the program will suggest the closest color within the gamut. Otherwise, for best offset printing results check out this illustrated guide of CMYK values. If you must use the out-of-gamut color, then we suggest printing it as a Pantone color.

How to Work with RGB and CMYK Profiles

Now that you know the differences between CMYK and RGB, the question arises: what is the best way to work?

The answer largely depends on your primary medium. If you’re creating work solely for print, like a flyer or printed program, you’re probably best starting in CMYK and staying there, since your work will never be viewed on a computer screen by anyone but you.

However, if you work in a medium that is primarily digital (like webcomics), working in CMYK to begin with will really limit the colors you have at your disposal, which for most creators is overly restricting.

In many cases, the best strategy is to work in RGB, then before printing, convert your files to CMYK and make adjustments from there to any colors that have shifted in undesirable ways.

Check out PrintNinja’s guide to converting your colors from RGB to CMYK.

Remember, you can’t physically achieve the exact look of your RGB colors using CMYK values, but if you get your colors looking the way you want them in CMYK mode, you’re going to have a much better idea of what your final printed product will actually look like.

Here’s a helpful guide of known CMYK values that produce vibrant results.

So that’s the long story! Remember, PrintNinja also has pre-press experts that review your files, so if you have more questions, you can always give us a call.

Freshly updated customer reviews from TrustPilot

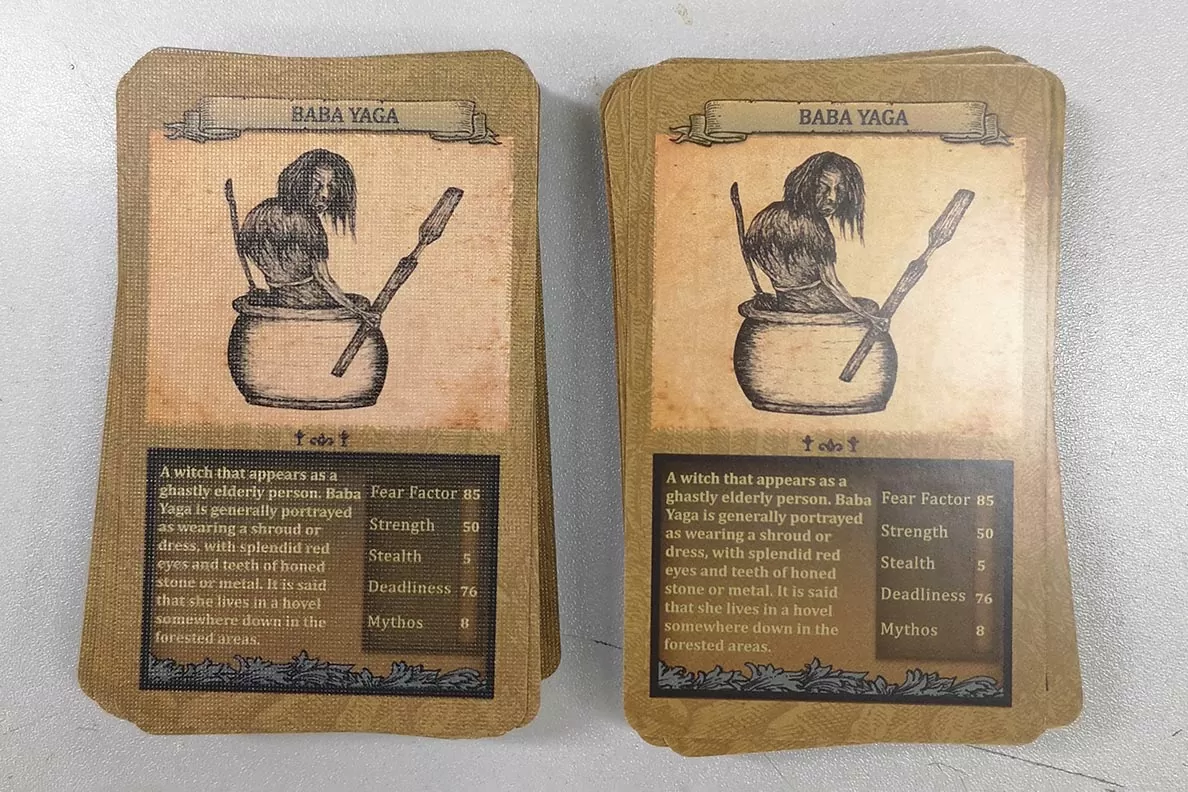

Color Variance

This article is about color variance in the offset printing process.

Due to the complex nature of reproducing a full spectrum of colors by blending 4 colors of ink (Cyan, Magenta, Yellow, and Black), all 4-color printing is subject to some small degree of color variance. This means that specific colors may look slightly different from the beginning of a run to the end of the run, and differences become more pronouned between different runs.

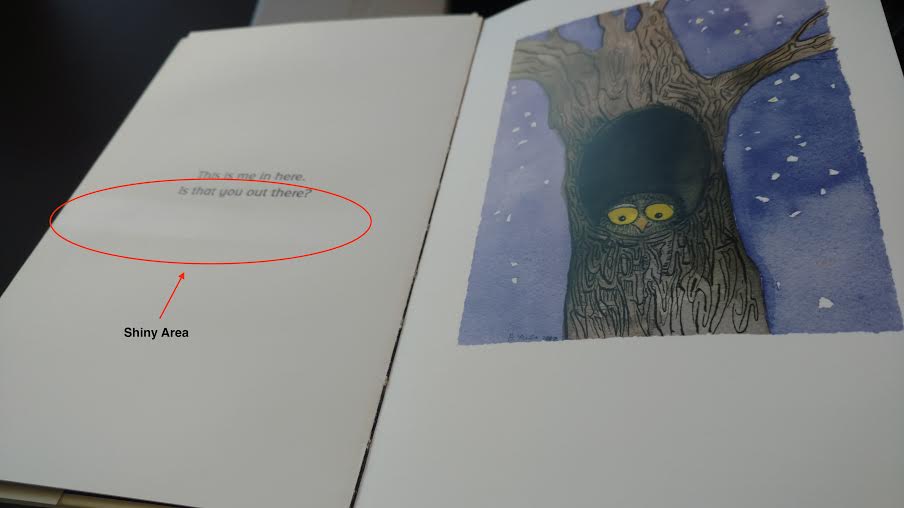

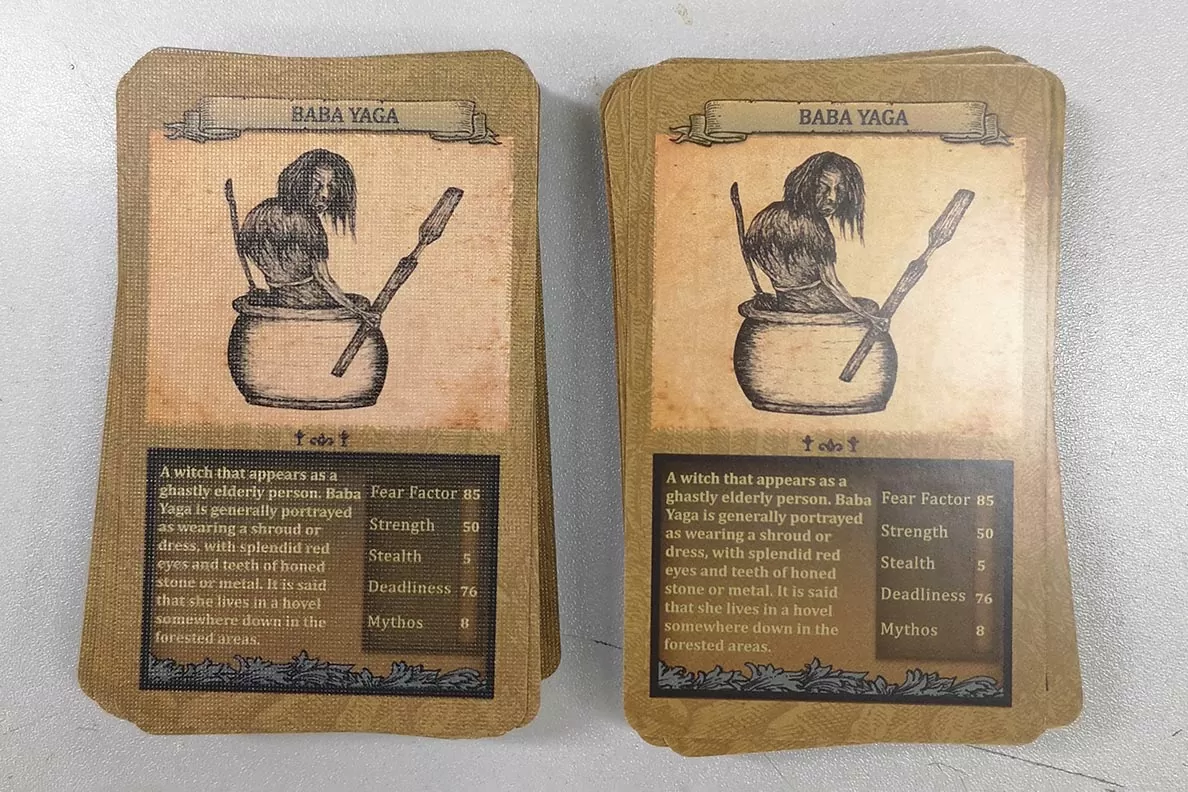

4-color offset presses are able to reproduce colors far more consistently than digital or print-on-demand presses, but the blending of inks means that there will always be some variance. This variance is most noticeable between different runs of the same project, as in the photo below:

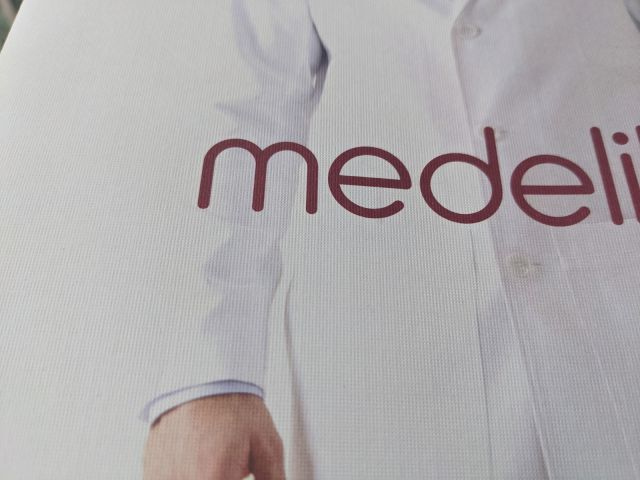

For individual colors that need to be exactly the same every time (e.g. a corporate logo), the color can be guaranteed by the use of a spot color ink. In this process, instead of using 4 separate colors of inks applied by 4 printing plates, the liquid ink is mixed separately until it exactly matches the desired color, after which it’s applied via a separate printing plate designed to apply only this single color. The specific color to be matched is most commonly specified using the Pantone Color Matching System.

Freshly updated customer reviews from TrustPilot

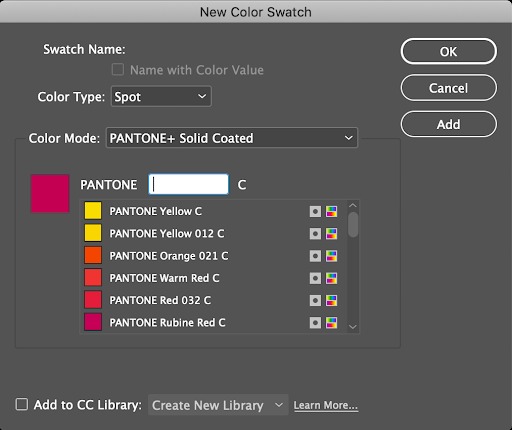

Pantone Spot Color

This article gives a detailed explanation Pantone spot color.

Sometimes, a specific color must be reproduced exactly the same every time it is printed (for example, a corporate logo). If that color were created through the standard application of 4 separate colors of ink (Cyan, Magenta, Yellow, and Black) during the 4-color printing process, it would exhibit very slight color variance between different print runs.

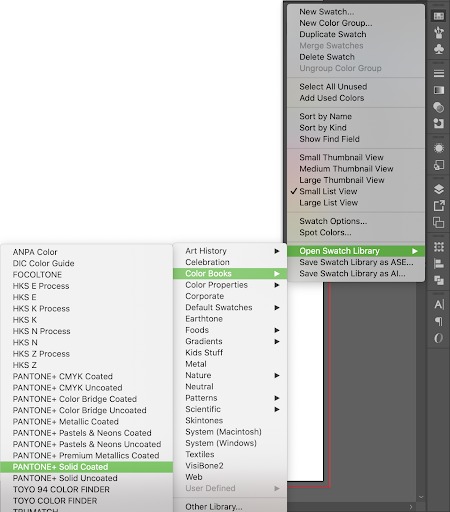

The only way to make sure a specific color looks exactly the same every time it is printed is to use what is known as a spot color. When using a spot color, the ink is pre-mixed to match the specified color, and is applied via its own printing plate. The most common way of specifying the exact color to be matched is by using the Pantone Color Matching System:

Because these colors can be made on their own without needing to consist of just Cyan, Magenta, Yellow, and Black, the color range of Pantone inks is far wider than the standard CMYK gamut, and it can include specialty inks such as metallic or fluorescent colors. Pantone colors are usually indicated by referring to their code: for example PMS 3245 is a bright, seafoam green.

Using spot colors always adds significant cost to an order, since they require prepress, printing plate manufacturing, press setup, and a press run for the extra color of ink to be applied. Metallic and specialty inks are also more expensive than standard 4 color process inks. However, when you need an exact color for branded materials like logos, or a specialty color that can’t be created by CMYK, they’re a great option.

The book to utilize when selecting your color is the “PANTONE FORMULA GUIDE Solid Coated (or Uncoated if the stock is uncoated)”. It’s important to note that we have a limited standard color selection for metallic inks, neon inks, and pastel inks. You can see the standard metallic ink color selections on this page here. Below are the standard offerings we have for neon and pastel inks:

Pastels

- PMS Yellow 0131

- PMS Red 0331

- PMS Magenta 0521

- PMS Violet 0631

- PMS Blue 0821

- PMS Green 0921

- PMS Black 0961

Neons

- PMS 801 – Neon Blue

- PMS 802 – Neon Green

- PMS 803 – Neon Yellow

- PMS 804 – Neon Orange

- PMS 805 – Neon Red

- PMS 806 – Neon Pink

- PMS 807 – Neon Violet

If you would like a neon or pastel ink outside of our above standard offerings, you will need to reach out to Customer Service or your Account Manager to make sure we can apply your unique color. Be prepared to send along the Pantone PMS color.

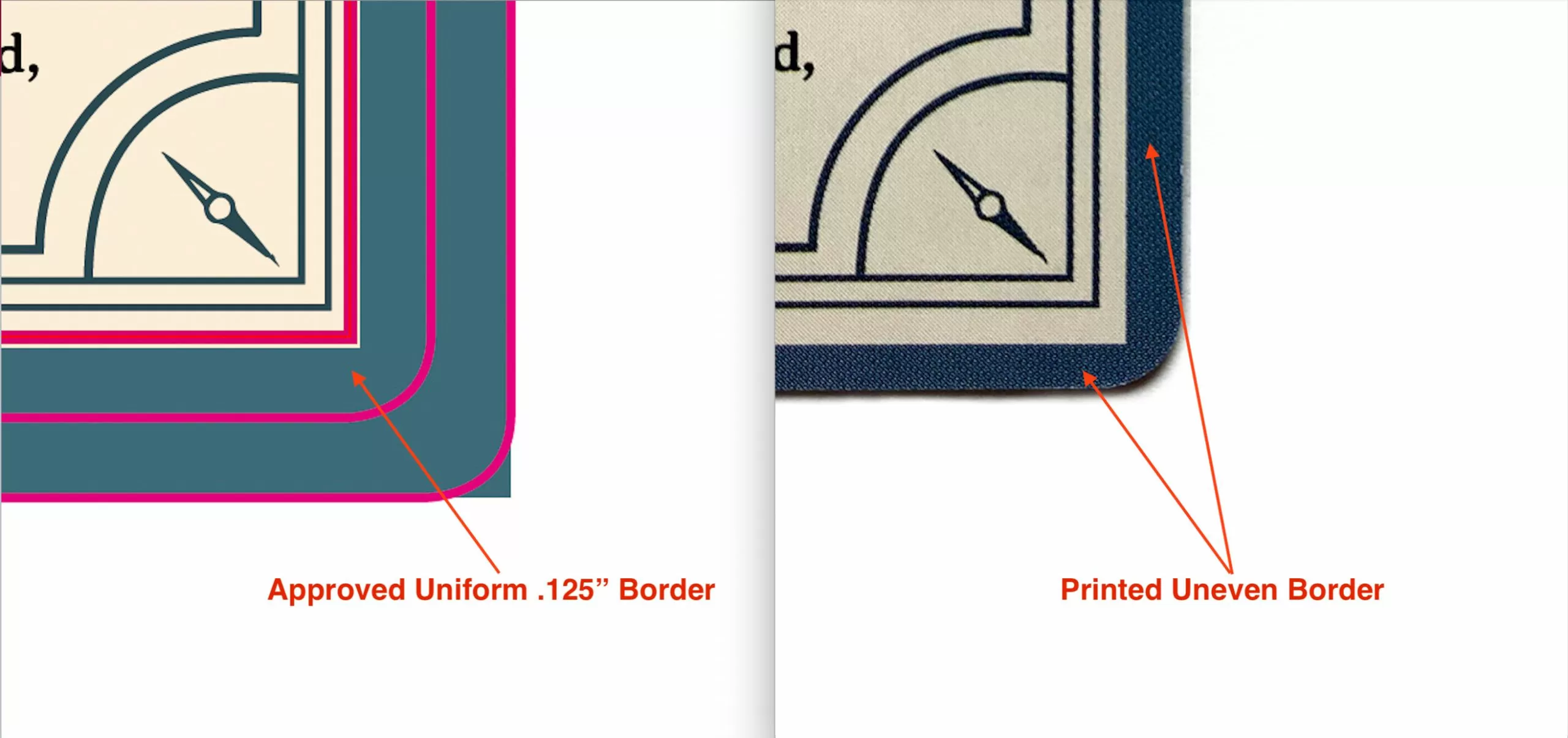

Manufacturing Variance

Learn what manufacturing variance is and why it’s important to understand when printing your project with PrintNinja.

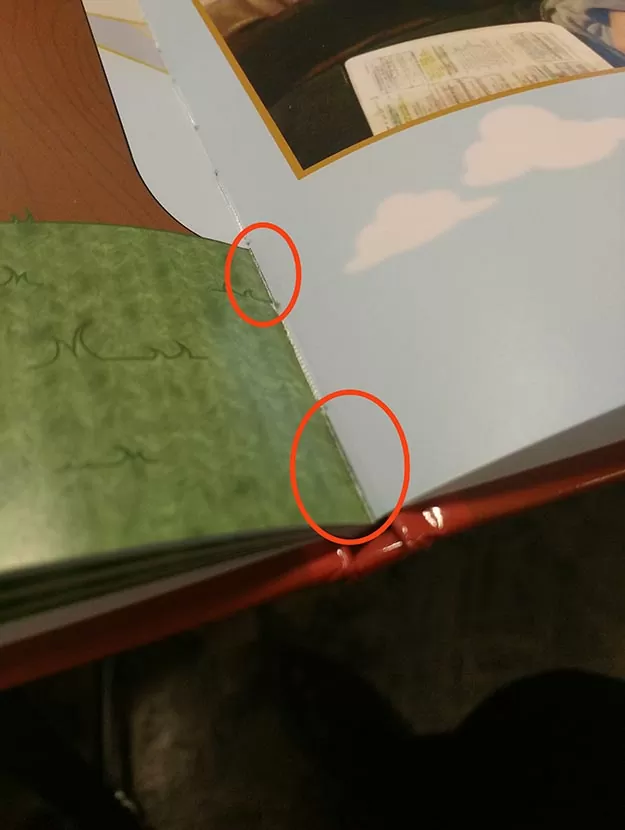

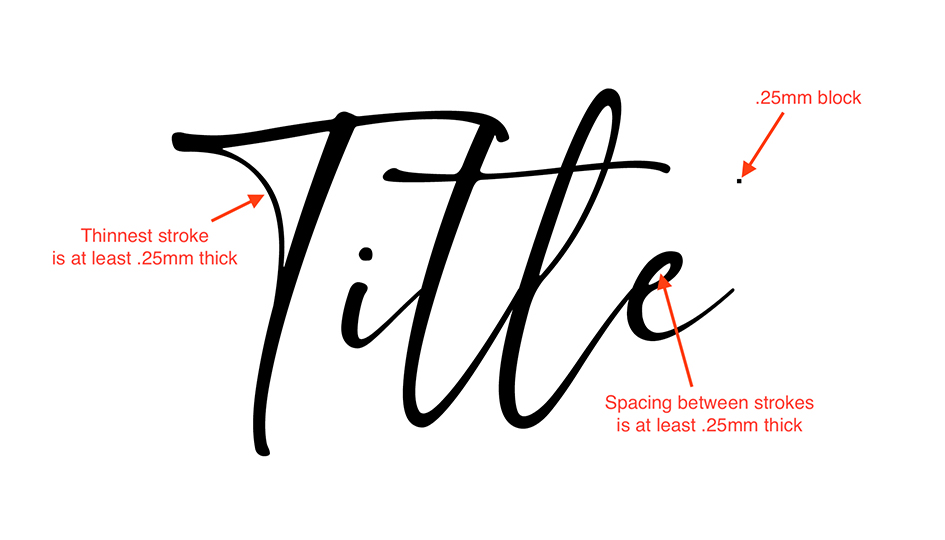

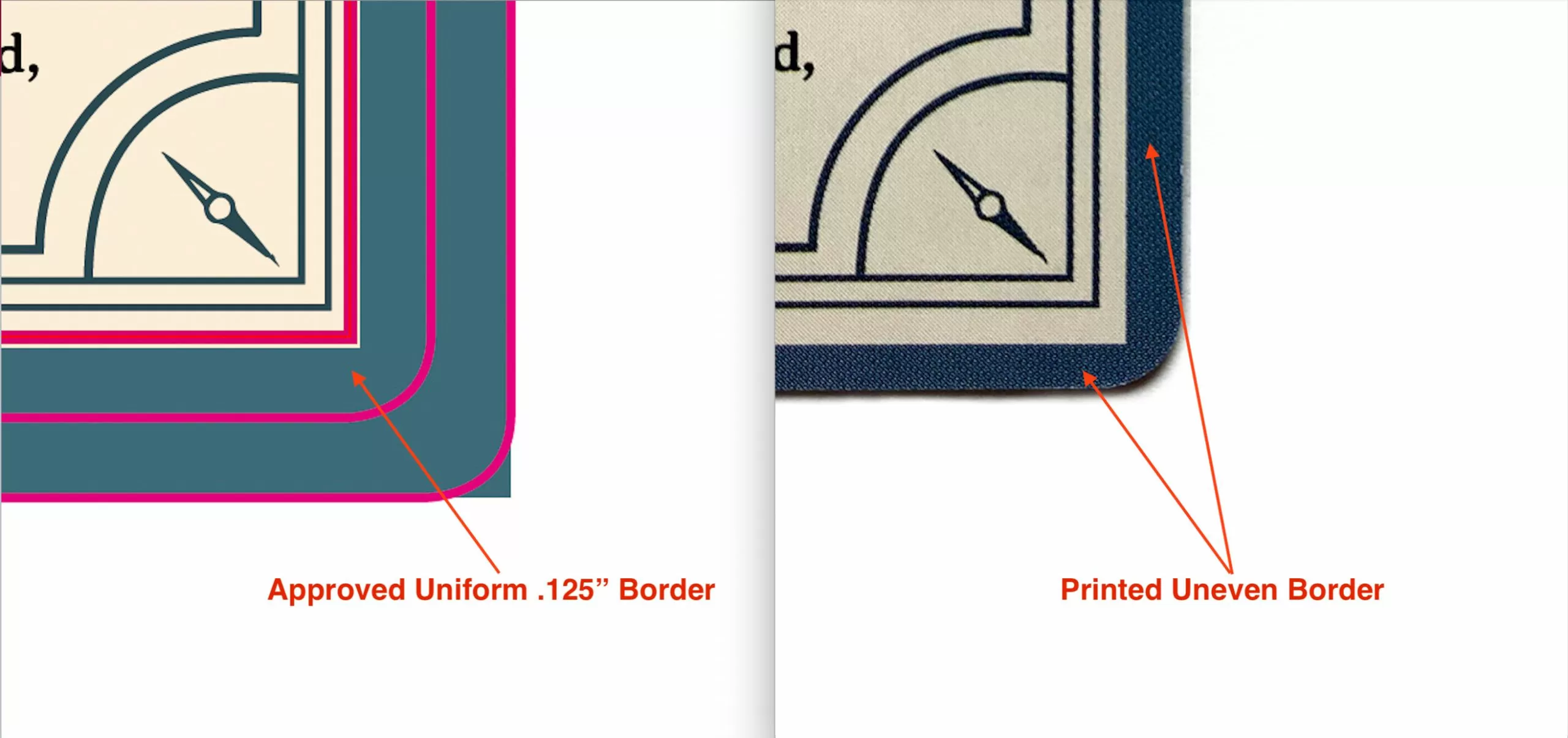

Sheet-fed offset printing quality can’t be beat, but as with any mechanical process, printing, trimming, and binding all exhibit miniscule variances (usually under 1mm) from piece to piece. This is why projects need bleed, for example, so that a cutting variance of 1mm won’t leave unsightly unprinted edges showing. While it’s impossible to avoid, we take all the steps we possible can to make sure your project ends up looking great. It’s also why we include a free 2% overrun – if there are any manufacturing variances you deem too severe, you can discard them and still be left with the same amount as your original run.

The most obvious and common manufacturing variances can be seen with specialty options such as embossing, debossing, hot foil stamping, and spot UV.

Watch the process of debossing a book cover:

It is difficult to get a spot UV, for example, placed exactly on top of your cover title without some pieces showing a millimeter of variance. It’s not extremely noticeable, but next time you are in your local bookstore take a close look at a few of the titles. Can you spot the variance?

Freshly updated customer reviews from TrustPilot

Board Book Binding

This article explains the process of board book binding.

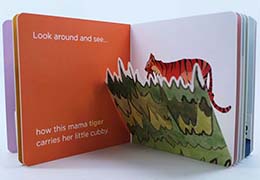

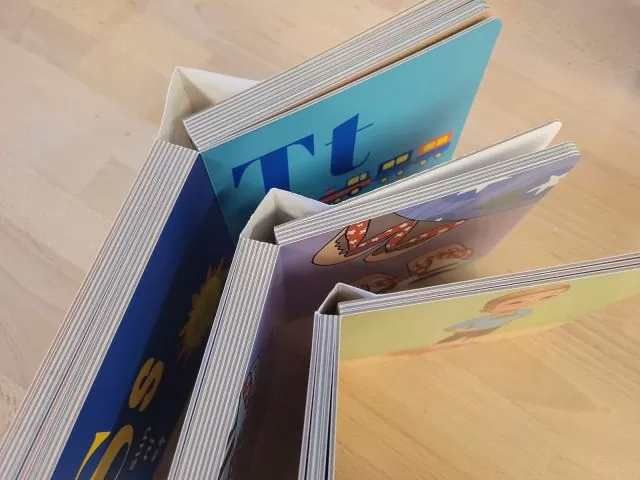

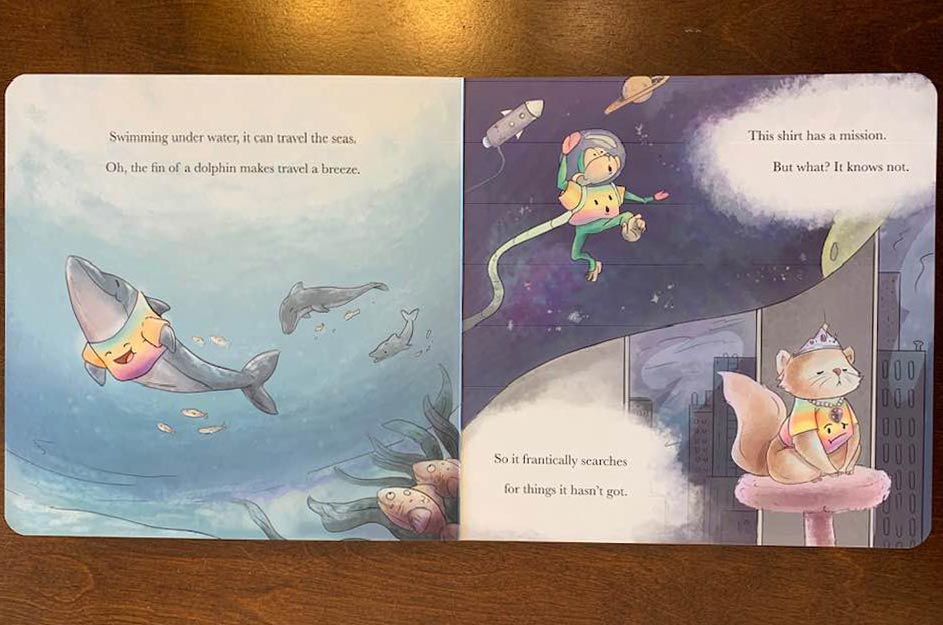

Board books are books with pages that are each made of thick paperboard rather than thin paper stock. This binding is perfect for children’s books, since the paperboard makes the book durable enough to survive a lot of hands-on attention from small children, while the thick paperboard also makes it easy for little fingers to turn pages without assistance. Most board books also use rounded corners to prevent paper cuts.

The board book binding methodology is not actually technically “binding” at all. Each set of 2 pages is printed, cut, and then glued by hand to blank paperboard. From there, each set of 2 pages is glued together one at a time. Finally, The cover paper is wrapped and glued around the body. Board books traditionally use a laminated finished on all pages, to increase durability and protect them from the intense handling they usually receive when in use.

Because these books are assembled by hand 2 pages at a time, they do not follow the standard page count multiple of 4 rule. Instead your final page count can be an increment of 2.

Freshly updated customer reviews from TrustPilot

Wire and Spiral Binding

This article will teach you about the process of creating wire and spiral binding. Read on to expand your knowledge about this type of binding!

For the process of creating wire or spiral binding, the book block is first trimmed on all four sides. Then, holes are drilled along one side and the pages are secured by either a wire that is clamped through the holes or a spiral that is threaded through the holes.

Because projects using this type of binding do not have to be stapled or sewn through the fold, they do not follow the standard page count multiple of 4 rule. Instead your final page count can be an increment of 2. That is great news if you have a project that has a page count that isn’t a multiple of 4!

This type of binding is most often used for calendars, cookbooks, and activity/workbooks. For all of these types of projects, the wire and spiral binding makes it possible for them to lay flat when open against a surface like a desk, floor, or wall. If you’re printing a project like this, then wire binding might be the right type of binding for you.

Freshly updated customer reviews from TrustPilot

Safety Testing

Safety testing for books is a certification requirement that rises from the Consumer Product Safety Improvement Act of 2008. The act was intended to make sure that products sold in the US were free from harmful materials. PrintNinja offers safety testing services through third-party labs based in Hong Kong. We offer the service for books as well as for games.

Safety testing for books is most commonly required when your book or game is targeted to a young demographic, especially when connected with anticipated distribution through a book retailer. Our board book printing customers, for instance, often submit samples for testing.

Games – especially those targeted to children under 13 years of age – will likely require additional testing or certifications. Games often use small pieces – dice, small tokens, even custom miniatures – that present choking hazards to young children. If you want to market a game to children, you may need to test to additional US standards so that your game is considered safe. Without testing, games can only be labeled for ages 13 and up. (It’s clearly better to design with the tests in mind, because it’s very expensive to fail a test for a game piece that you have tooled up and purchase many thousands of before you get into testing!)

If you are targeting distribution in Europe for books or games, you may also want additional safety tests to verify that your game meets all CE marking requirements.

All of that said – we have never had a product fail a safety test. The likelihood that a printed book would fail a test is quite low. The materials that are used in printing today simply aren’t the kind of materials that are subject to contamination from lead, phtalates, or other dangerous compounds.

The attachment below is an example of the output of a safety testing for books request that we performed in 2017. The test was for a board book, and the output is representative of the output that satisfies insurance companies and distribution partners.

Sample pdf of toxicity testing results.

Freshly updated customer reviews from TrustPilot

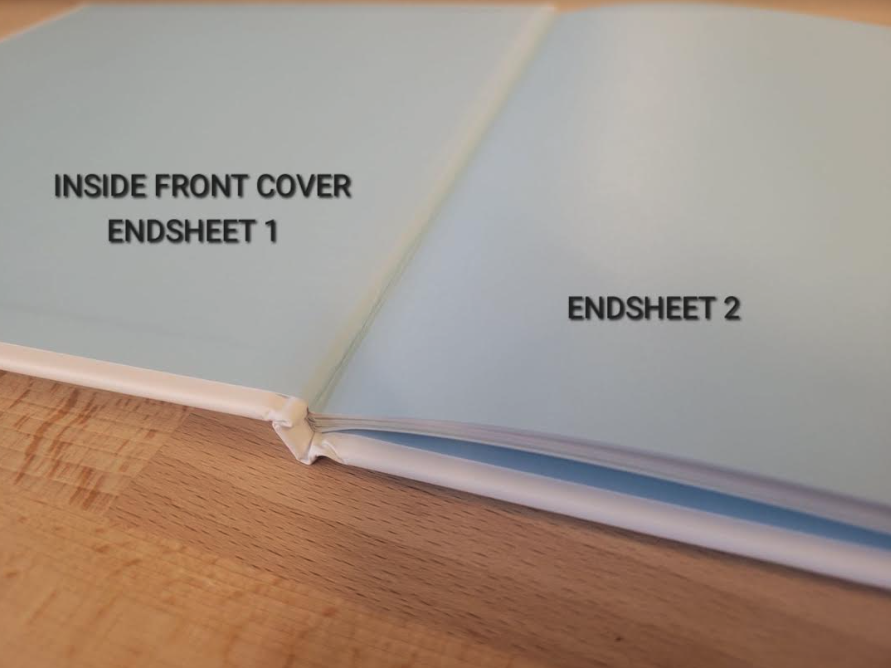

Endsheets

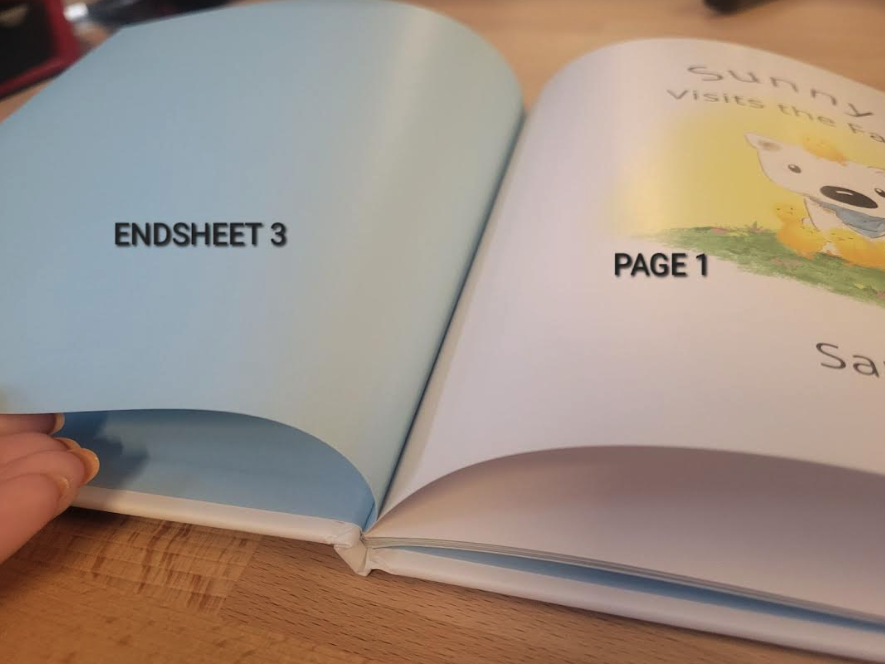

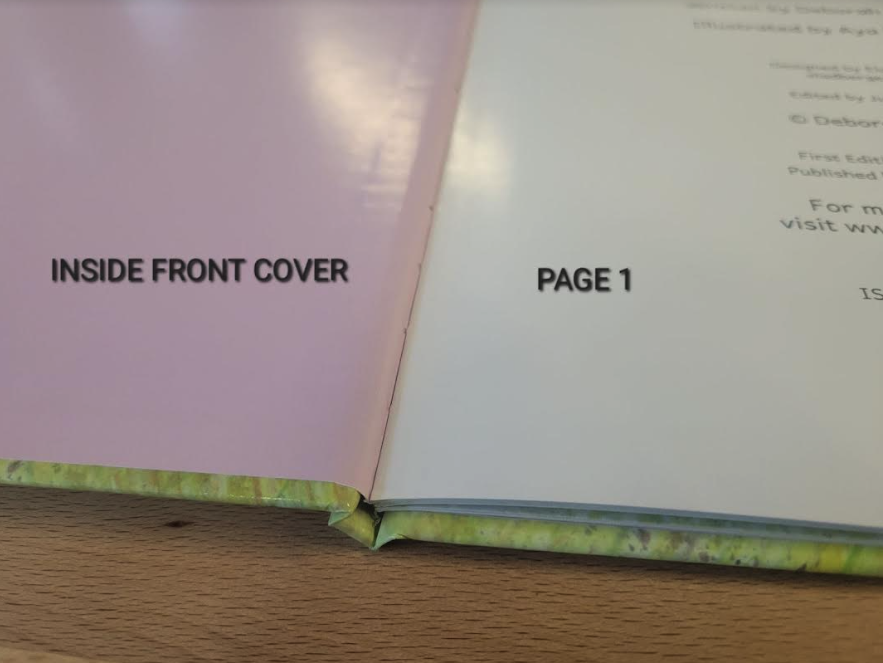

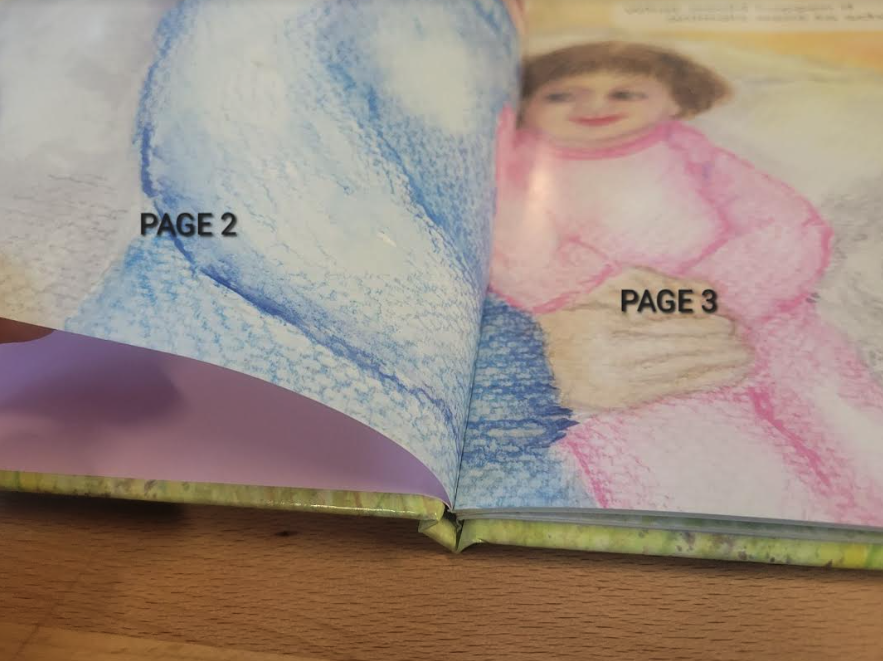

Endsheets, or endleaves, refer to the pages at the beginning and end of hardcover books with at least 60 pages. They are typically made of a 105lb uncoated paperstock that fortifies hardcover books and adds durability. Endsheets are printed as a two-sheet spread. One side of the spread is glued down on the inside back and inside front cover of your book:

When getting a quote or preparing your project files, remember that endsheets do not count toward your interior page count. However, they need to be included in your interior page file. The endsheets should be the first three pages and the last three pages of your interior page file. Let’s say you have a project that is 64 pages. Your interior page document should include 70 pages. Pages 1-3 are the front endsheets and pages 68-70 are the back endsheets. This leaves 64 additional pages, hence, your final page count of 64. Check out this link to an example page file (PDF).

Endsheets can make counting your interior pages a little tricky, so if you need some extra help, check out our video guide here!

When Endsheets Aren’t Needed

Casebound books under 60 pages don’t include endsheets unless requested through a custom quote. If your casebound book does not have endsheets, the pages glued to the hardcover case will be your inside front and back covers:

Regardless of whether or not your casebound project includes endsheets, or traditional inside covers, printing is included! Endsheet pages and inside covers are typically left blank, printed with a solid color or a pattern, but the design is totally up to you!

Fabric and Endsheets

Hardcover books are also reinforced with fabric, known as the super. The super is glued to the spine during the binding process to strengthen the spine and prevent pages from tearing. In the image to the right you can see the fabric underneath the endsheet lining the spine for added strength.

Freshly updated customer reviews from TrustPilot

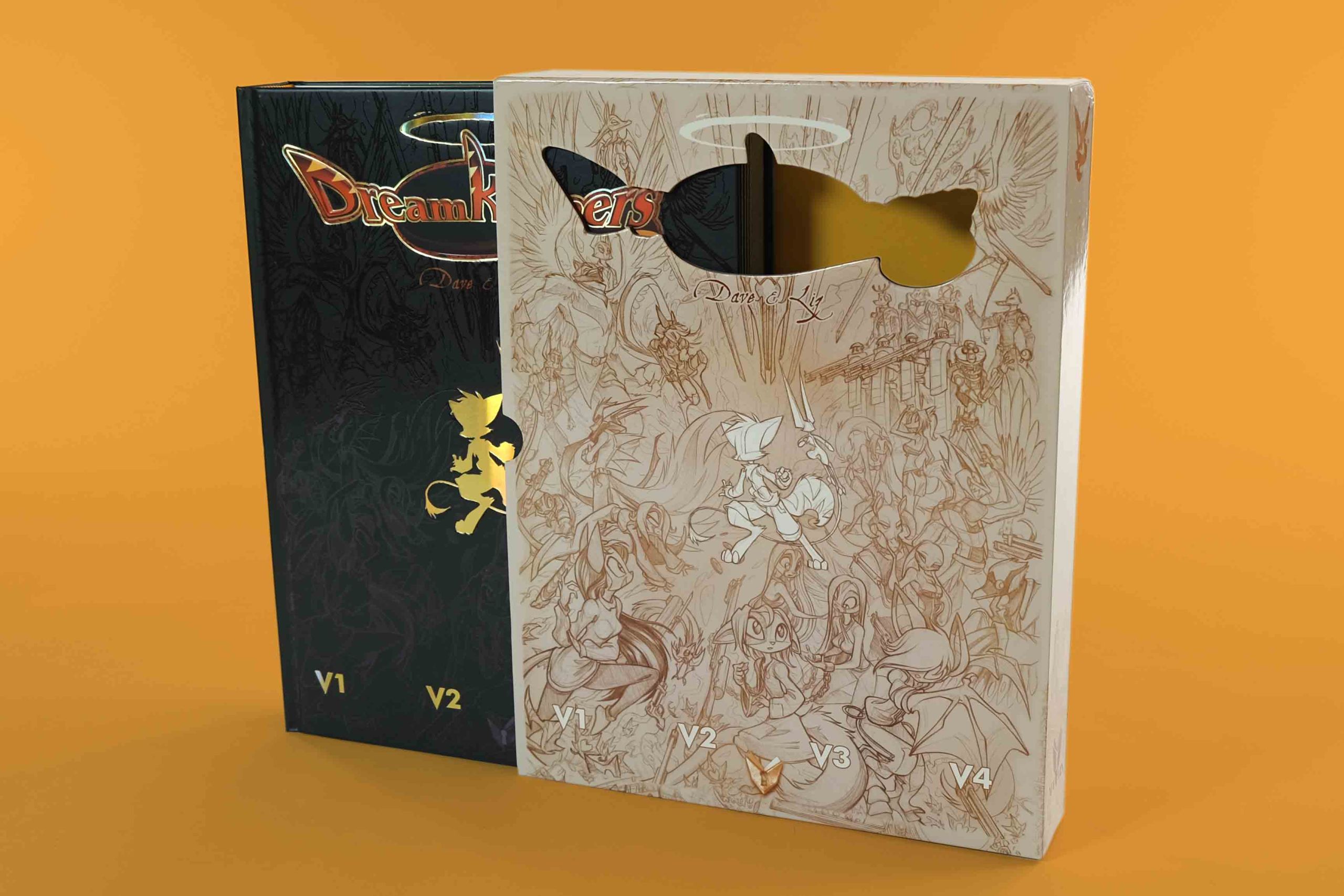

Foil Stamping Process

This article will teach you about the hot foil stamping process.

Hot foil stamping is the application of adding metallic material to a project using heat and pressure.

A key player in the foil stamping process is the hot foil machine. Hot foil machines are run manually by an operator who makes sure each project gets stamped correctly. The operator measures the project and places markers on the machine’s platform in a formation that allows the project to be slipped snugly inside. The formation also takes into account where the foil stamp needs to be placed. Once everything is set up, pieces are hand fed into the machine one by one until each piece has been stamped.

Foil stamping uses a heated metal die to transfer the metallic material; your digital art file is used to create this die, so all pieces will be stamped with the same shape.

Sequential Foil Numbering

Sequential foil uses a specific machine, as seen to the right. Instead of using a single die, these machines use a die with a rotating numbered head so that each piece gets its own unique number.

Hot foil stamping process in action